Arkieva Supply Chain Link Blog.

Creating the link between better supply chain planning and decisions.

How Tariffs Are Shaping Supply Chain Risk Management

Learn how tariffs impact supply chain risk management and what proactive strategies leading companies are using to stay agile, resilient and competitive.

Beyond the Grid: What the 2025 Gartner® Magic Quadrant™ Means for Supply Chain Planners

Explore key takeaways from the 2025 Gartner® Magic Quadrant™ and learn how to evaluate supply chain planning solutions for today’s complex business needs.

Supply Chain Planning in Light of Tariffs

Can your supply chain planning withstand the uncertainty of tariffs? Organizations that leverage what-if scenario planning will be a step ahead.

Evaluating Supply Chain Planning Solutions: Key Takeaways from the 2024 Gartner Critical Capabilities Report

See how Arkieva performed amongst 20 vendors in the 2024 Gartner Critical Capabilities Report for supply chain planning solutions use cases.

Tariffs & Supply Chain Management: Complexity, Robustness and Responsiveness

Leverage supply chain management software and central planning models to survive against tariffs and market volatility.

How to Successfully Implement Supply Chain Planning Software

Learn how to implement supply chain planning solutions effectively with expert insights and practical strategies to avoid delays and maximize ROI.

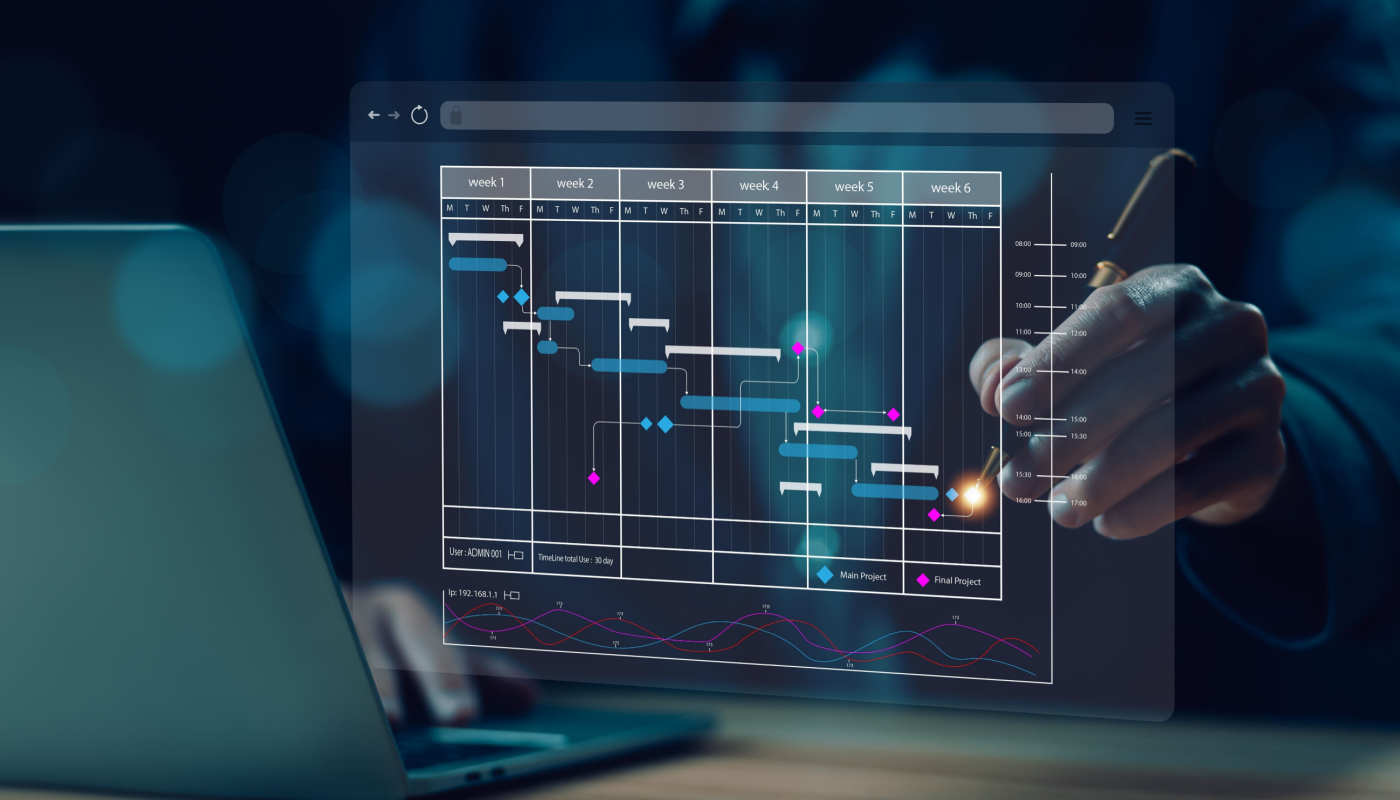

Supply Chain Scheduling Best Practices: Developing the Tools to Execute your Supply Chain Plan

If supply, inventory and demand planning are building materials, scheduling is the tool that helps you assemble them. Learn best practices of effective production scheduling.

How to Select and Implement Supply Chain Planning Software for Long-Term Success

Struggling to choose and implement the right supply chain planning software? Learn key strategies to streamline selection, ensure smooth adoption and drive ROI.

Artificial Intelligence: Getting a Handle on a Moving Target

Artificial intelligence for supply chain is a hot topic. Uncovering misleading claims and understanding the differences between types of AI is crucial.

Top Blogs of 2024 (Plus Some Supply Chain Analytics Blasts from the Past)

From supply chain analytics to demand planning best practices and beyond. Here’s a roundup of 2024’s most popular blogs, including a few blasts from the past.

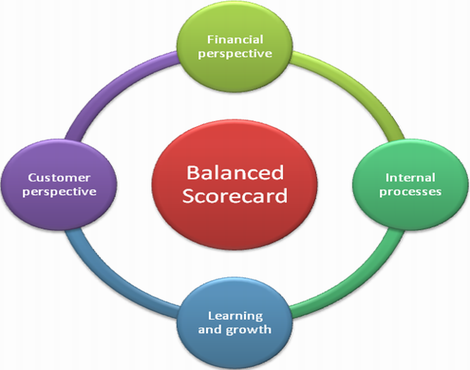

KPIs: More Than Metrics – They’re Tools for Change

Learn how to design effective supply chain KPIs that drive organization change, align teams, and improve performance with actionable insights.

5 Supply Chain Planning Mistakes That Will Haunt You

Curbing bad habits or errors early is essential to effective supply chain management. Look at supply chain planning mistakes that haunt you if not corrected.

Demand Planning Best Practices: Practical Advice for Harmonizing Demand and Supply

Proactively sense and respond to changing customer demands with effective demand planning. These best practices will help set your business on the right path.

The Balancing Act: Lot Size vs. Production Constraints

Understanding and balancing lot size vs production constraints is a common juggling act in supply planning for manufacturers. Learn how to balance them.

Maximize Profit With Supply Chain Optimization Software

Squeeze the greatest profit possible from the resources your business already has available. Supply chain optimization software identifies the most valuable demand to meet.

Digital Supply Chain Transformation: Keys to Success

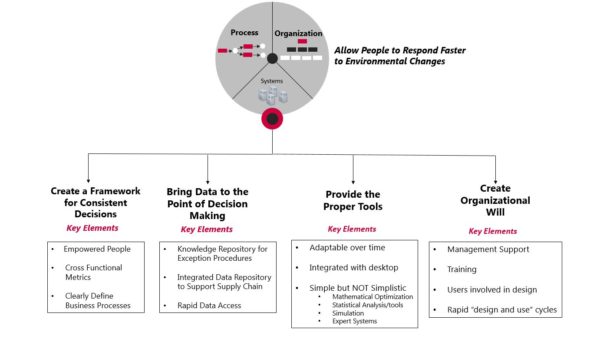

Discover strategies for successful digital supply chain transformation. Learn how to focus on people, processes, and technology to overcome common challenges.

2024 Gartner Critical Capabilities Report Supply Chain Planning Recognizes Arkieva

Explore the latest Gartner® Critical Capabilities Report and its impact on supply chain planning. Discover why Arkieva is recognized in the industry.

Maximizing ROI Value from Your Supply Chain Software Investment

Learn how to maximize ROI from your supply chain software with best practices, advanced features, and continuous optimization strategies.

Essential Concepts for Successful Responsiveness: 7 Steps to Improve the Scheduler’s World

This blog covers 7 seps to improve scheduling, essential concepts for successful responsiveness, including data requirements and managing objectives.

Building the Business Case for Supply Chain Planning Software Implementation

Calculating expected benefits and demonstrating ROI for supply chain planning software implementations are critical. Attend our webinar and learn how.

Essential Concepts for Successful Responsiveness: Planning versus Scheduling Basics

Understanding the difference between planning and scheduling basics will help achieve responsiveness which is increasingly important in the ever-changing world.

4 Common Production Scheduling Problems that the Right Software Solves

Minimize changeover time and maximize utilization and production efficiency. Avoid common production planning and scheduling software missteps.

What the Economic Outlook Means for Demand Planning

Forecast as accurately as possible, even in uncertain economic conditions. Review demand planning strategies that can help you navigate hazy market conditions.

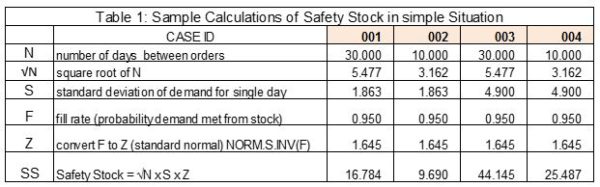

Avoiding the Assumption of Normal Distribution in Safety Stock Calculations

Explore alternatives beyond the norm in the world of safety stock calculations. Join our webinar to break free from distribution assumptions.

Arkieva Named Challenger in 2024 Gartner® Magic Quadrant™ for Supply Chain Planning Solutions

Arkieva recognized as Challenger in 2024 Gartner Magic Quadrant for Supply Chain Planning, empowering businesses with cutting-edge solutions.

Unwrapped: What You’ll Take Away from the 2024 Gartner Supply Chain Symposium

Make the most of your time at the 2024 Gartner Supply Chain Symposium/Xpo in Orlando. Preview the can’t-miss speakers and supply chain planning topics.

The Latest R in Sustainability: Reshoring

As awareness of climate change and globalization grow, the list of Rs in sustainability is also growing. This blog explores the latest trend: reshoring.

Unpacking S&P Global’s 2024 Supply Chain Industry Outlook

Mitigate supply chain risks. Review our analysis of S&P Global’s 2024 Outlook to assess the challenges and importance of building resilient supply chains.

How to Improve Forecast Accuracy

Forecast accuracy is at the top of the list of things that help a business plan better for the future. This blog previews how to improve forecast accuracy.

A Journey Through Safety Stock, Part 11

This blog is the latest part of the story of Kate and Jane as they navigate the concepts of safety stock at Jane's company and focuses on variance terms.

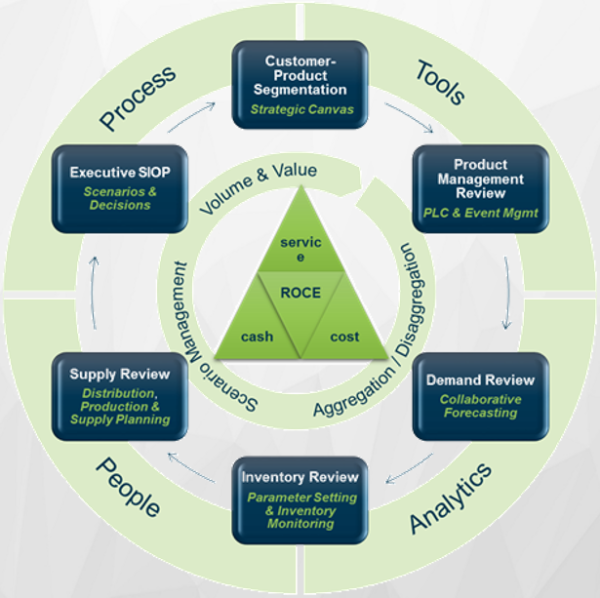

What is S&OP?

What is S&OP? In a world where you can easily get overwhelmed by the number of supply-chain related acronyms, S&OP is one you don't want to overlook.

An Artificial Intelligence-based Solution to Sudoku

This blog celebrates National Puzzle Day by detailing how to solve a Sudoku puzzle using artificial intelligence.

A Journey Through Safety Stocks, Part 10

This blog continues the journey of Kate and Jane as they navigate the concepts of safety stocks at Jane's company.

Top Reads of 2023: Unveiling Our Most Popular Blog Posts

From insightful industry analyses to practical how-to guides, our blog demonstrates the diverse range of supply chain-related topics we cover.

8 Things that Should be on Every Demand Planning Wish List

Effective demand planning positively impacts everything from production to inventory, distribution to marketing—and all steps in between.

How to Calculate Safety Stock and Evaluate Different Methods

Uncertainty and volatility have been around for decades. There are several methods of leveraging safety stock in the supply chain to mitigate risk.

Using What-if Scenario Planning to Balance Supply and Demand

Scenario planning provides a framework and set of tools to help planners pinpoint risks and opportunities, offer recommendations and more.

Seen and Heard at CSCMP EDGE Supply Chain Conference 2023

Key observations from the Edge Conference for Supply Chain, including the impact of generative AI and the gap in skills that is an outcome of this trend.

Navigating the Pitfalls of Expedited Shipping

In the dynamic supply chain management landscape, one of the most challenging aspects is dealing with the differences between our forecasts and reality.

The Consequences of Complacency

Complacency can quickly make supply chain planning software obsolete. We lose when we "wait and see". Now is the time for investment and improvement.

How to Build the ROI Case for Planning and Scheduling

Planning and scheduling of manufacturing operations can be likened to going on vacation. Our next live webinar builds the ROI case for planning and scheduling.

Planning Ahead: 2024 Business Investment and the ROI of Supply Chain Planning Software

As 2023 comes to an end, it's a good time to plan your business investment strategy for 2024, and that should include supply chain planning software.

Arkieva Helps Fight Childhood Cancer

Arkieva is proud to sponsor Jeff Ondria on his 4th annual Great Cycle Challenge and support efforts to raise money for the Children's Cancer Research Fund to fight childhood cancer.

A Journey Through Safety Stocks, Part 9

This blog continues the safety stock discussion between Kate and Jane as they evaluate historical sales and lead time data.

Boosting Efficiency: The Value of Scheduling Software

Scheduling software is similar to GPS, organizing the movement of items, marking process steps, ensuring expected locations, and optimizing the route.

Understand the Factors Behind Inventory Accumulation by Optimization Models with No Demand

While working with various optimization models, I often encountered situations where the supply chain optimization model would make decisions to produce items even when there was no demand. This blog discusses different scenarios that led to the optimization models producing and storing excess inventory.

How to Achieve Better Operations Scheduling

This blog previews our free webinar where Sujit Singh discusses his learnings from the schedulers and planners he has had the good fortune to work with.

How Does Arkieva Support Client Success?

This blog features a few of our client success stories. Read more to see how Arkieva helps clients achieve their business objectives.

The State of Just-in-time Supply Chains

Prior to Covid-19, a lean, just-in-time global supply chain model was ideal. Fast-forward and you may be wondering - how did the JIT supply chain model fare?

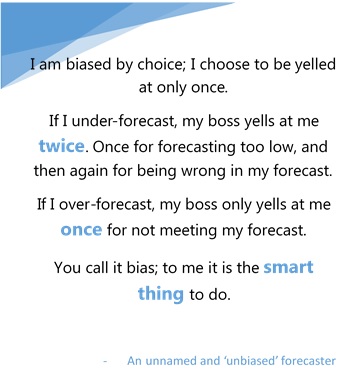

Why Planning Forecasts Are Wrong and What You Can Do About It

Predicting the future is difficult, yet forecasting remains a critical tool for businesses to plan and prepare for what lies ahead.

How Can A $150MM Manufacturer Compete with Larger Players?

Supply chain disruptions can have a higher impact on smaller manufacturers. How can you keep up with Fortune 1000 companies?

A Journey Through Safety Stocks, Part 8

This blog continues the discussion between Kate and Jane as it relates to the unit of measure as the input demand.

How Can Smaller Manufactures Navigate Competitive Supply Chain Planning Pressures?

In the fiercely competitive landscape of manufacturing, companies with revenues ranging from $50 to $250 million often find themselves under pressure from both smaller and larger competitors. This article explores the competitive pressures faced by manufacturers in this revenue range and provides insights into effective strategies for mitigating these factors.

How to Improve Your Statistical Forecast Using Machine Learning

Our latest webinar examines the varying definitions of machine learning and artificial intelligence while discussing how they can be leveraged to improve your statistical forecast.

5 Ways Artificial Intelligence Impacts the Supply Chain

The adoption of machine learning and artificial intelligence is on the rise, but not at the pace of other transformations. Here are a few reasons why.

SOS(C): Shorten Our Supply Chains

What is a shorter supply chain and what are the benefits of shortening a lengthy supply chain? This blog discusses this and more.

Are You Caught in the Middle?

Do you fall into the gray area of companies who require advanced planning capabilities but lack the resources of larger companies? Arkieva+ is for you.

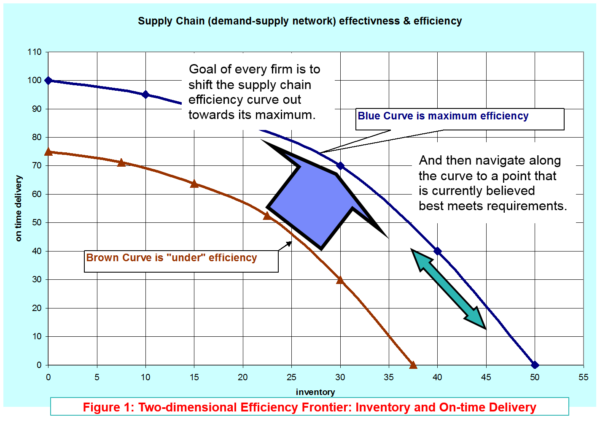

Is Your Supply Chain Effective, Efficient or Neither?

This blog previews our webinar on effective supply chains and the difference between efficiency and effectiveness.

What Stops Businesses from Adopting Planning Software?

Learn common factors that hold companies back from implementing supply chain planning software - according to ChatGPT and our experts.

A Journey Through Safety Stocks, Part 7

This blog continues the discussion with Kate and Jane and covers variance and cycle service level.

A Journey Through Safety Stocks, Part 6

This blog continues Jane and Kate's discussion on safety stocks through the lens of histograms.

Asking “What if?”

Now is the time to ask “what if” we enhanced our forecasting with technology that can work with or replace Excel?

How to Select Effective Dashboard KPIs

This blog previews a webinar that discusses how to find the best data to drive your integrated business planning processes.

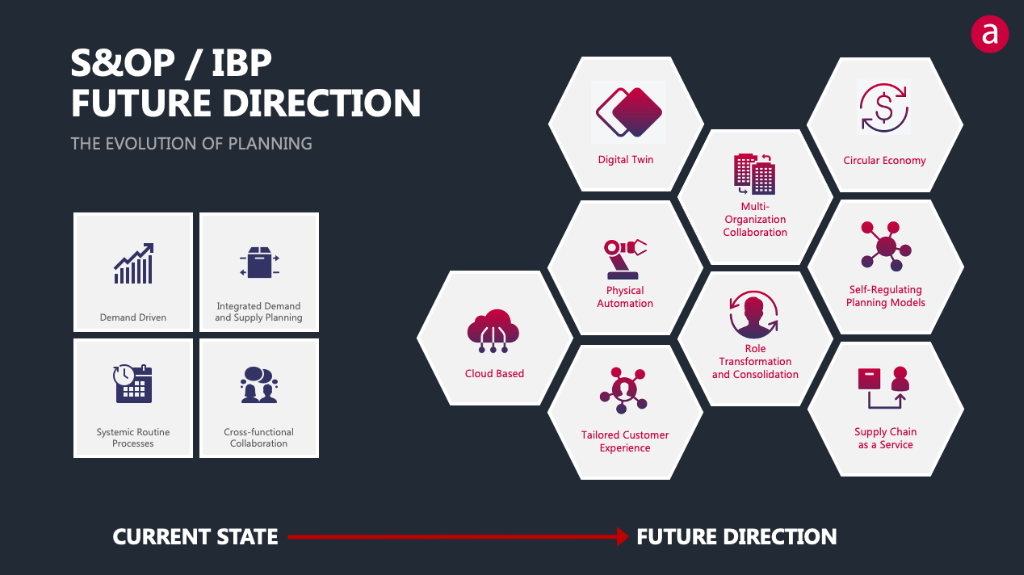

Sales & Operations Planning vs Integrated Business Planning

Are you ready to move beyond S&OP to integrated business planning? This blog covers key considerations for implementing IBP.

Why Now is the Time for Arkieva+

Digital transformation has been a prime area of focus over the last 10 years. Arkieva+ is our answer for smaller businesses looking to implement a SaaS solution.

The IBP Implementation Journey

Implementing IBP is a difficult journey. This blog previews a free webinar that discusses various challenges associated with the implementation of IBP.

A Journey Through Safety Stocks, Part 5

This blog dives deeper into the connection between safety stock and service levels, continuing our series on safety stock.

Why Are Our Supply Chains Broken?

Ever worsening weather, a global pandemic and labor shortages have generated a perfect storm that’s pushed global supply chains to their breaking point.

Effect of Change in Replenishment Frequency

This blog breaks down the impact of changing replenishment frequency on inventory and service levels from a mathematical perspective.

The Difference Between Knowing and Acting

New tools can use AI to respond to queries, but can they really replace the value in the difference between knowing and acting?

Building the ROI Case for Inventory Planning

Companies often focus on inventory to free up working capital. An inventory planning solution often requires presenting management with ROI.

Surviving the Impact of Holiday Returns on Demand Forecasting

Businesses can almost guarantee a jump in returns following the holidays. How can you account for returns in your demand forecasting?

Our Top Blogs of 2022

Each year, visitors read our supply chain blog to take advantage of all that we have shared. This is the round up of our top posts.

A Journey Through Safety Stocks, Part 4

This blog covers the importance of lead and cycle times when calculating safety stock and other things to consider.

A Journey Through Safety Stocks, Part 3

This blog continues the discussion of Jane's safety stock journey, where we'll cover an option when you're unsatisfied with your results.

A Journey Through Safety Stocks, Part 2

This blog discusses the importance of adjusting and refining safety stock approaches to balance inventory.

What Do Thanksgiving and the Supply Chain Have in Common?

From demand and safety stock to production capacity and sustainability, what do the supply chain and Thanksgiving have in common?

Battle of the S&OP Methods

This blog discusses the pros and cons of the three most common S&OP methods: top-down, bottom-up and countercurrent planning.

A Journey Through Safety Stocks, Part 1

Inventory planners have a difficult task balancing customer demand with inventory levels. This blog is the first in a series discussing safety stock.

5 Questions About Safety Stock Calculations

There are various approaches to safety stock calculations. This blog previews a free webinar that sheds light on the pros and cons of each.

Is It Time to Renovate Your Supply Chain Planning Software?

Are you a supply chain planning firefighter? Learn more about the value of keeping your technology current and the dangers of relying on an outdated system.

What Does Your Pantry Have in Common with Inventory Management?

Unlike a fine wine, inventory does not get better with age. Learn more about the importance of balancing inventory levels with related costs.

Where Are You Investing in 2023?

Investments typically fall into the familiar categories of people, process, and technology. So, what does this prioritization mean?

Is Warehousing Imperative to Reduce Logistics Costs?

Logistics costs account for a large portion of final costs. This blog explores whether warehousing can help optimize the logistics process.

Demand Planning by Segmentation-based Exceptions

Demand planners are facing unprecedented pressures caused by the all-time high number of planning combinations. Supply chain planning software can help.

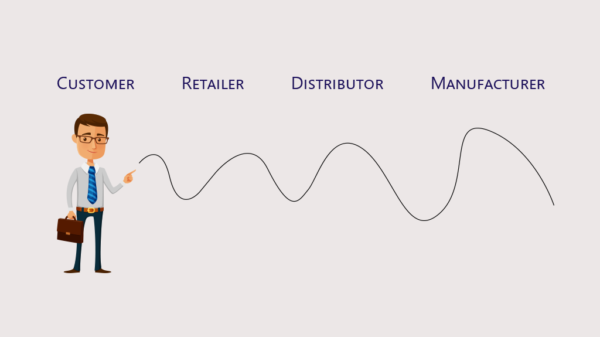

How to Mitigate the Bullwhip Effect in Today’s Market

One flick of the wrist triggers a wave of disruption that grows the deeper it penetrates the supply chain. This blog explains the bullwhip effect, how the pandemic exacerbated it and tips on how to mitigate the effect.

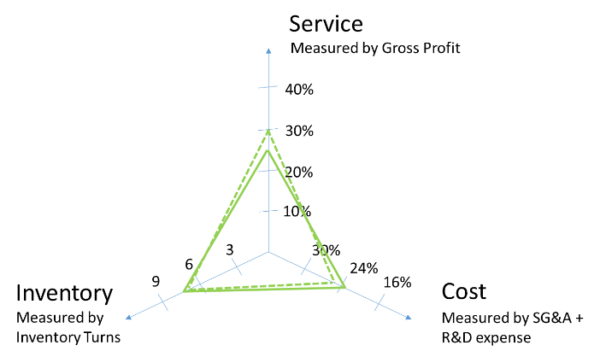

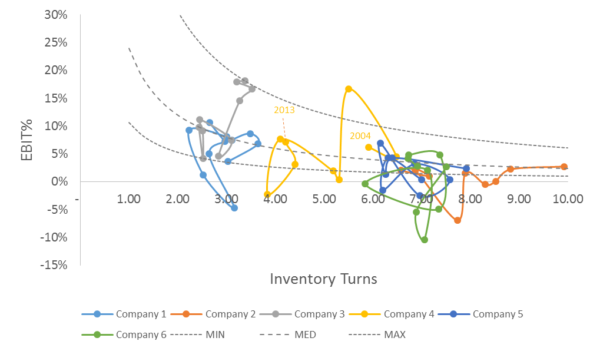

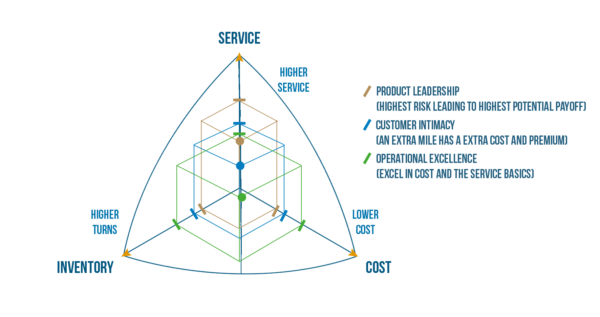

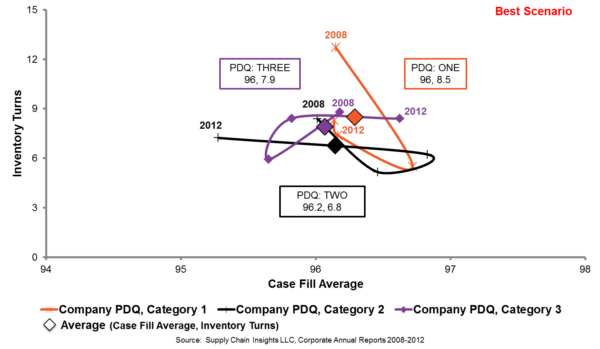

Managing the Complex Network is Key to Profitable Growth

Dr. Ken Fordyce shares his takeaways from Gartner's free webinar on the performance lenses that supply chain leaders must apply and balance.

Lessons Learned from a Complex Transformation Project

Common language, silos, process vs progress and utility vs value are important considerations when undertaking a complex project.

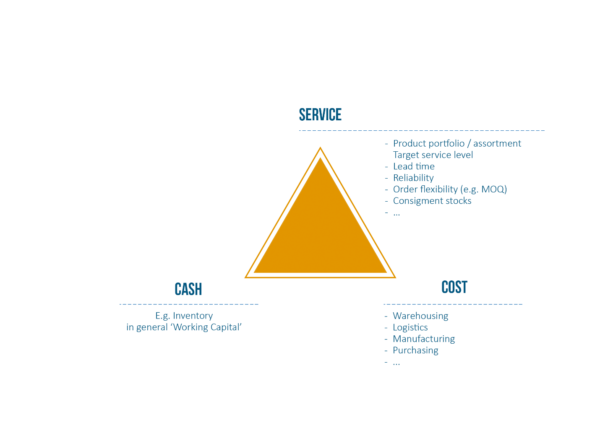

3 Must-have Inventory Planning Software Features

Every supply chain planner’s goal is to provide the highest degree of customer service while

How to Have a Serious Conversation About Inventory

Whether you are a manufacturer, retailer or distributor, inventory is likely one of your largest assets – after cash of course. Managing this asset takes a cross-functional team, all (hopefully) moving in the same direction. Weak management of the inventory process results in a porous supply chain.

Suggested Summer Reading from Arkieva

It’s the midpoint of summer and a good time to catch up on “summer reading”. For us at Arkieva, that means digging into industry reports and predictions. Here are a few articles that recently caught our eye.

Demand Patterns Inside a Period

Demand forecasting is often done in planning buckets such as months or weeks. But what about the pattern of demand inside a period? Whatever pattern it is, a demand planner should strive to understand it.

Rules-based Approach to Supply Planning: Matching Assets with Demand

In any supply chain, matching the supply assets to the demand in a consistent, reliable, and profitable manner is a key requirement. This blog discusses how to create supply plans based on a sequence of rules that makes the decision-making process fast, effective, and intuitive.

Which Came First: Supply Chain Woes or the Recession?

The next recession is at our doorsteps. Let’s discuss what we can do to rise to the latest challenge.

Seen and Heard at the 2022 Gartner Supply Chain Symposium | Xpo

The Gartner Supply Chain Symposium 2022 was filled with insights, actionable strategies, trends and more. Here we cover a few highlights.

7 Must-Attend Sessions at the 2022 Gartner Supply Chain Symposium | Xpo

This year’s recommended sessions range from executive leadership to lessons learned to simply getting the most out of the most recent Gartner Magic Quadrant for Supply Chain Planning.

The ROI of Inventory Reduction

A lot of projects propose to deliver ROI through lower levels of inventory. Servicing the demand at desired service levels with lower inventory should save the company some money. But how, exactly?

FAQs: Digging into the Arkieva Virtual Mailbag

We’ve spoken to a lot of people over the years. Here are the answers to some of our most commonly asked questions.

5 Steps to a Global Collaborative Demand Planning Process

Every business can benefit from having a proper demand plan. A pivotal part in this process is collaboration.

The Hippocratic Oath for Forecasters

Is there an equivalent to the Hippocratic Oath for forecasters? What harm(s) can a forecaster easily avoid? This blog explores some examples.

The Intersection of Supply Chain and Customer

Countless businesses around the globe are rolling out new products, building out infrastructure, and fighting for market share. In these disruptive times, there is immense pressure for supply chain leaders to deliver the goods despite strong supply-side headwinds and fickle customers.

Tools of the Trade: Production Activity Alternative Views – “Starts” and “Outs”

Since the beginning of time, alternate but related views of production have existed: historically called “starts” and “outs”.

What is the ‘Secret Sauce’ to Improve Demand Planning?

Successful demand planning requires a stable and sustainable planning process that is continuously reviewed and improved.

5 Key Supply Chain Assessment Benchmarks

If you're looking to improve your supply chain management systems, these quick tips can help you get started.

Building the ROI Case for Demand Planning

Businesses spend a lot of time and money in improving their demand planning. However, the ROI is not always forthcoming. How much is a 1% improvement in forecast accuracy worth to the business?

Part 3: How NLP Benefits the Supply Chain – Internal Structured Data

This blog discusses how utilizing a semantic parsing method can help a less experienced user transform their data questions into advanced database queries, and how it can help detect errors in datasets.

Survey Says: Modernize Your Supply Chain IT

It seems we are always reinventing ourselves to meet the latest challenges. Often the solution comes down to managing people, process, and technology.

Part 2: How Natural Language Processing (NLP) Can Benefit the Supply Chain – Internal Unstructured Data

We know how to deal with structured data but working with unstructured data might be a bit more time consuming and challenging. There are multiple solutions that NLP offers to transform your unstructured enterprise data to structured data.

The Wrong Inventory Approach Can Strangle Production Output

Successful management of inventory is a hot topic in supply chain management. While it's easy to measure, the cause may be complicated to uncover.

10 Ways to Buffer Supply Chain Risk

In today’s highly globalized economy, no country can remain isolated or insulated from the outside world. The world is so interconnected that one hiccup can cause a myriad of issues downstream.

The Importance of Product Mix in Capacity Planning

When engaging in capacity planning, it is important to consider the product mix and seasonality of your business to ensure an effective and accurate outcome.

Managing Supply Chain Transformation Beyond IT

Senior leadership engagement, business process analysis, and proper communication ensure a successful supply chain transformation.

Some Good Supply Chain News, For a Change

Despite all the bad news regarding container ships stacked up at ports, pandemic related labor challenges, and chip shortages, there have been a few bright spots regarding the supply chain. The general ideas around vision, technology, and sustainability apply to all of us.

Part 1: How Natural Language Processing (NLP) Can Benefit the Supply Chain

As more and more individuals utilize supply chain software, there is a need to simplify its usage. The next step in evolution can be Natural Language Processing (NLP) where the user expresses a desire in plain language, and the software translates it to queries in the background. This and other use cases such as the automation and analysis of content have made NLP an area of prominent growth.

Tools of the Trade: National Puzzle Day, Probability and the Board Game Risk

National Puzzle Day is January 29th. It is a day Arkieva celebrates because the ongoing challenge of smarter supply chain decisions involves supersized puzzles and games. This year we will focus on probabilistic forecasting using the board game Risk. This blog will show how Monte Carlo Simulation can be used to estimate the average number of “wins”, but critically the range of possible “wins” across some interval.

Tools of the Trade: Characteristics of Agents of Change Teams to Drive Successful Investment

In previous “tools of the trade” blogs, the focus has been on conveying a basic understanding of core technologies critical to improving supply chain management decision making. Other blogs have focused on investing in technology. As with any investment there are risks to success. This blog focuses on the need for a small group driving technology that upsets the social order called agents of change (AOC).

Top 5 Signs You Have Outgrown Your Planning System

Industry analysts, big-time consultants, and your peers are all talking about technology, digital transformation, and the future of the supply chain. It can seem like a lot of noise given the day-to-day pressure you feel while working to ensure that inventory is on hand and positioned where it is supposed to be. With all you have on your plate, are you aware of the signs that it is time for a change?

What To Expect in 2022: Arkieva’s Take on 2022 Supply Chain Trends

With the new year comes pundit “prediction season”. It seems that anyone who can type will post their list of things to look out for. It’s human nature to look ahead and anticipate what may be. We all look back to look forward – just like a good demand forecast does. And if you think about it, most calendar-year business plans are in truth, predictions about the year to come.

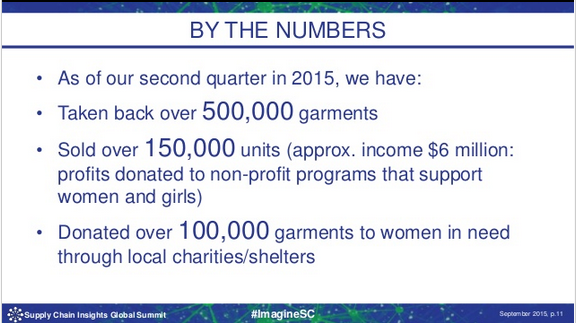

Managing Distribution in Circular Supply Chains

Circularity, in the form of re-use, is not really new as a business model. Look at Goodwill, Habitat For Humanity’s Re-Store, and countless local consignment and thrift stores. eBay, Etsy, and Facebook Marketplace provide an online forum to convert one person’s trash to someone else’s treasure. A quick trip to the post office and the deal is sealed. Waste averted.

4 Barriers to Capturing True Demand

If one is going to forecast demand into the future, it would make sense to get as true a picture as possible. For that, starting with historical demand would be the obvious choice. Choosing this data as the basis for forecasting would ensure the best possible projection out in the future.

Automated Forecasting: Finding the Handshake Between Demand and Supply

Having a good forecast is essential to demand planning. It ensures the right goods are produced at the right time and reach the right customers. What’s more is that demand planning is situated at the start of your supply chain, playing an integral part in a streamlined supply chain.

Subscription-based Supply Chain Systems

Subscribe and save makes planning easier. Consistent demand means less fluctuation in order volume, which makes forecasting, inventory management and scheduling more predictable.

Our Top Blogs from 2021

Arkieva prides itself on providing some of the best in supply chain thought leadership. Over 300,000 individuals read our blog articles in 2021. The volatile nature of the supply chain today drove our readers to educate themselves on practical actions they can take to remain competitive.

Announcing the New Arkieva Brand

We are excited to announce that we are rebranding Arkieva to fuel growth, strengthen our position in the market, and continue to be a recognized leader in the supply chain industry. Over the past few years, we have been relentlessly focused on solving the most complex planning challenges through simple, intuitive, end-to-end solutions leveraging our best-in-class data scientists, software developers, and supply chain optimization consultants.

How “Forecastable” is Your Data? It’s Complex Anyway You Look at It

These “key tools” balance a need for simple with a need to handle the complexity of SCM – following the IBM adage – complexity exists whether you ignore it or not, best not to ignore it.

Pyramid Forecasting Process

One of the many ways to improve the forecast is to forecast using a pyramid process, starting at the base, then forecasts the subsequent levels moving upwards. The objective of using the pyramid forecast process is to use the less detailed portions of the pyramid to improve the base level forecast of the pyramid.

Going Beyond Historical Data for Forecast Accuracy

Our focus in this blog series has been to establish forecast accuracy targets. In very general terms, the goal should be to add value to the business through the forecasting process. We have however focused on the forecast value add and using that to create a minimum acceptable forecast accuracy target in the previous blog. Now we will take that a step further and talk of ways of improving it.

The Ongoing Shipping Container Shortage and Possible Effects on Tomorrow’s Supply Chain

We have all seen it in the news. Covid-19 outbreaks, labor shortages at the port as well as in trucking, and port delays coupled with high demand from consumers are causing major supply chain issues. Shipping containers are in short supply, or perhaps a better way to say it is that they are waiting to be unloaded or loaded resulting in a shortage. In this blog, let us try to enlist some possible future impacts of this situation. Let us look at it from the perspectives of the different players in the supply chain.

What is Happening to Our Supply Chains?

Everyone is talking about supply chains these days. Ever worsening weather, a global pandemic, and a labor shortage have generated a perfect storm that has pushed global supply chains to their breaking point. I propose that the problem has been building for some time and this perfect storm may just be the reset we need.

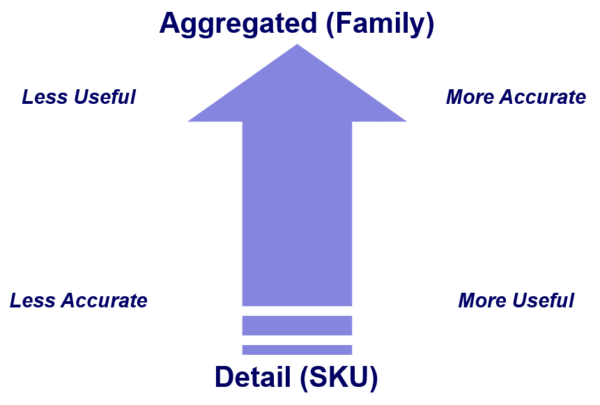

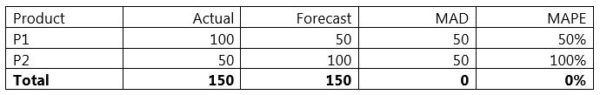

3 Aggregation Mistakes When Reporting Forecast Accuracy

It is important to measure and improve the forecast accuracy at the right level of aggregation. If you measure at too high a level, your accuracy picture will look better than what it needs to be as the data at high (aggregated) levels is more forecastable. By contrast, at too low a level...

How to Choose the Right Demand Variance Method to Calculate Safety Stock

In today’s blog, we will share some examples to help Inventory Planners explore different methods available to calculate Demand Variance and decide which method is best suited for their products and businesses.

Sustainability in Supply Chain Planning: Waste or Revenue?

When many companies produce products, they also produce by-products. Often, they have no use for these by-products and so they are discarded or sold off as scrap. But companies that embrace sustainability do not accept this fate. Some companies have found a way to turn their waste streams into revenue streams...

Automated Forecasting

A successful demand planning process accurately forecasts demand and revenue streams, and subsequently drives the next steps in the S&OP process which are Inventory, Supply Planning, and Optimization. Therefore, it is a crucial step in an organization's S&OP process.

RCCP Versus MPS: How Are They Connected? Elixirs and the Wrong Question

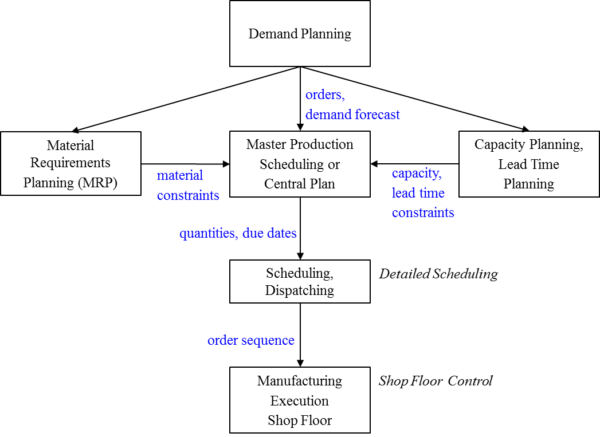

A reasonable question supply chain folks often ask themselves is ‘What is the relationship between Rough Cut Capacity Planning (RCCP) and Master Production Scheduling (MPS)?’ However, this is the wrong question to ask oneself. This blog will address the transition from AS to central planning as best practices and demonstrate that with a firm’s due diligence they can make the transition successfully. This is critical for what-ifs and effective use of optimization.

The Relationship Between Forecast Accuracy and Safety Stocks

A company’s total inventory consists of many types of stock such as strategic, anticipation, safety, cycle, and unplanned. Cycle stock is most connected to the demand forecast; it is expected to be sold as the forecast becomes real demand. Safety stock on the other hand is extra stock to deal with the variability of the demand or supply. As such, it is not always linked to forecasting accuracy.

An Approach to Setting Forecast Accuracy Targets

Learn the best approach to setting forecast accuracy targets and how to set expectations for your management team.

How Forecastable is Your Data?

Having access to an accurate forecast is very beneficial for businesses. If used correctly, it can provide better margins, increase market shares, and many other positive results. At a more tactical level, it can help reduce the costs associated with meeting the customer demand and make the supply chain more efficient.

Data Science Tools of the Trade: Rolling Rounding to Handle Those Pesky Decimals

In many areas of supply chain management, analytic methods generate estimates with “pesky decimals”. The traditional method to eliminate the decimals is rounding. In this blog, we demonstrate the importance of this method and how to calculate these improved integer estimates.

Two Penny Model and COVID-19 Breakthrough Cases – Avoiding Data Driven Disaster

Learn how a simple binomial model can help anticipate the future including COVID-19 breakthrough cases just as models help a firm estimate it's future.

Sustainability in Supply Chain Planning: In Practice

Integrated Supply Chain Planning is the best way to be sure that you are running your business in a way that is best for your whole business. When you address your energy needs independent of your supply chain planning you can drive up costs unnecessarily and create rework. Industrial gas companies know this better than most because their production process is an extremely energy-intensive one. Keeping energy use to its minimum is a pinnacle of smart sustainable business practices.

Classical Supply Chain Management Confronts its Quantum Revolution – the Path to Rapid Intelligent Response (RIR)

COVID-19 direct and ancillary events have made clear that uncertainty is an inherent part of the demand-supply network structure. Every firm, on a regular basis, faces “risk situations" such as manufacturing excursion, unexpected new demand or loss of demand, component supplier interruption, etc. This has placed risk management and rapid intelligent response (RIR) front and center in SCM discussions.

Five Steps to Develop an Effective S&OP Process – Step 4: Balance Supply and Demand

Over the past 5 weeks, Jeff Ondria has hosted a set of short interviews on LinkedIn about the five distinct steps to develop an effective S&OP process. In today's blog, we discuss step 4 Balancing Supply & Demand where we will answer some key questions with respect to balancing supply and demand.

Effect of Lockdowns on Essential Goods Value Chain

These interesting times that we are currently living through have thrown open a lot of challenges. Organizations and decision-makers must be agile and innovative to overcome the challenges that COVID-19 has thrown at us. In India, we had 2 lockdown periods in the last 15 months. Being a supply chain student, I try to watch and analyze day-to-day situations with a lot of interest and I see one area that needs improvement when lockdowns are implemented.

Using Coefficient of Variation to Drive Safety Stock Related Decisions

In a previous blog post, we discussed how a high or low value of Coefficient of Variation (CV) impacts the first or second term of safety stock. Today we decided to put this to the test using real customer data - here we will discuss our findings.

CPE Planning Level, IBP, Elixirs, and the Ongoing Challenge

In SCM there is an ongoing flow of elixirs (magic potion) from ‘false prophets’ claiming that they are an easy path to improved performance. A recent elixir is IBP followed by “doing central planning at the family level” to neutralize the uncertainty associated with estimating demand at the product level. This blog will illustrate the challenge in this effort since factories produce products, not families.

Data to Decisions. Faster.

Arm your supply chain planners with the right software tools so they can turn your data into better business decisions.

How to Use What-if Scenarios to Create a Dynamic IBP Paradigm

Taking the time to perform what-if analyses on a regular basis with real and speculative events, gives planners tremendous insight into what parts of the supply chain are most sensitive to changes. As a result, planners will have a sense of what is a big deal and what is not. And when a crisis happens, they’ll feel confident in their ability to respond.

Target Inventory and Central Planning Engines (Models) – Avoiding the Runaway Train

Often inventory is considered the simplest component of supply chain management that can successfully be managed separately. The purpose of this blog is to provide some observations to avoid the runaway train. We will first review the basics of CPE and then address the use of target inventory (specifically ending finished goods inventory EFGI) in CPEs.

Sustainability & Circularity in Your Supply Chain Planning

Learn how climate action relates to supply chain management. Achieving full-scale sustainability and circularity cannot happen without end-to-end alignment, hierarchical connectivity, integration of all parts of your supply chain, performance metrics, and business processes. And this alignment needs to be part of your existing supply chain before you can take it to the next level.

Tools of the Trade: How to Compare / Combine Diverse Time Series – “Normalizing”

A reoccurring challenge in comparing and combining diverse time series in demand forecasting is the “scale” – as it is in combining metrics. Rescaling is a powerful but simple method to help with this issue enabling demand planners to focus on similarities of shape. This blog provides an example of one method called normalization.

How to Combine Diverse Supply Chain Metrics

Learn how to combine very different metrics/KPIs towards a composite score, this is a question that comes up quite often in my conversations with customers.

Supply Chain – Finance Connection: A Supply Chain Improvement Case Study

In this blog, we will demonstrate the link between Finance and Supply Chain and how this understanding can help define supply chain improvements by understanding elements of the Balance Sheet and Income Statement.

Pandemic Induced Supply Chain Issues

Recently, we have heard about several product shortages and other issues in the supply chain. Let us try and make sense of some of these in this blog. As I live in the US, my experience is somewhat limited to what happened here.

AI/ML, SCM, The Holy Grail, and Helpful Information from Foresight

In this blog, we point the reader to a recent article “Humachine”, which identifies the general challenge of implementing decision technology to improve SCM decision making resulting in improved organizational performance and the importance of experience in the trenches.

Time Series Forecasting Basics

In this blog we briefly cover some key insights for successful time series forecasting: (a) Profiling the Shape of the Curve is the first stage, and the first step is assessing if the time series is stationary. (b) The forecast method identified must capture the shape and be able to project the shape across time. (c) There are limits in historical and no amount of “fancy math” can overcome them.

Lessons From the Suez Canal Blockage – Supply Chain in the News

In the past few days, the news of the blockage of the Suez Canal by a massive container ship called the Ever Given has been dominating the news, so much so, that even kids are talking about it. The phrase ‘supply chain’ is now being mentioned more often than ever before in news media. Some outlets have estimated the cost...

Hierarchical Supply Chain Planning – S&OP to Execution

For your business to effectively carry out the supply chain planning process, you will need to link up your short-term and medium-term, to the executive level S&OP plan so that it drives your tactical planning and operational planning.

Arkieva Recognized as Visionary by Gartner

We are pleased to announce that due to the amazing support of Arkieva customers, Arkieva has been named as a Visionary in the 2021 Magic Quadrant for Supply Chain Planning Solutions.

Supply Chain Planning Improvement Implementation Steps

We often see companies wanting to make the transition from spreadsheet-based planning to a best-of-breed supply chain planning system. There is often a question about where to start, what the foundational elements are, and which are the more advanced elements.

Guide to a Successful Leap to Warp Speed in Central / Supply Planning – LP Genie

Learn when it is time to move from RCCP to LP Genie for your CPE as part of your organization’s journey pulling from years in the trenches and current ongoing activities with clients.

Cost and Complexity – Factory Perspective on Inventory Golden Rules

The purpose of this blog is to explain a basic costing challenge in factories and their impact on critical SCM analysis and decisions.

Building the Business Case for Sales and Operations Planning (S&OP)

Making the business case for Sales and Operations planning is not always easy given that you will need to bring on board key decision-makers in your organization. Let us explore how one can go about making the business case for a proposed S&OP project.

Trim Loss Optimization

In this blog, we will explain the basics of trim/loss and further explore the potential disasters from failing to manage the big picture.

Using ABC Analysis to Determine Off-Balance Inventory

In this blog are some analyses based on the Pareto principle (or as is very commonly referred to as ABC analysis) that one can do in order to determine the alignment of the inventory with the overall needs of the supply chain.

Sudoku and SCM: The Binary Connection – A Path To Smarter Solutions

An earlier Sudoku blog recognizing Puzzle Day, provided an overview of solving Sudoku using MILP optimization and mentions these methods are helpful to find solutions in supply or central planning. This blog elaborates on “binary variables” which is the connecting technology between Sudoku and Supply Chain Management (SCM).

National Puzzle Day – Solving Sudoku Puzzle Using Optimization in Arkieva

I learned this morning from my LinkedIn feed that January 29 is national puzzle day. So, we decided to put out a fun blog to mark the occasion. We have tried to solve Sudoku using a Mixed Integer Program (MIP). This blog is unrelated to Supply Chain although we use the technique used here to solve supply chain problems. Please enjoy!

Demand Planning: Differentiated Forecast Strategy

Some time ago, I had been trying to help a business improve its statistical forecasting. We tried different parameters and different forecasting algorithms but the statistical forecast for about half of the products could not be improved no matter what we tried. We decided to do a deep dive to understand the reason.

Supply Chain Planning Transformation

I was asked recently about what it takes to transform the supply chain planning process of a company. Having gone through this process a few times in my past, I thought it best to share my experiences and suggestions in the form of a discussion with Tapan Mallik during a webinar. This blog is a precursor to that webinar.

Sales & Operational Planning (S&OP) Versus Integrated Business Planning (IBP)

With strong leadership by the executive team, over time, the business begins to think in terms of overall health and welfare of the company, rather than optimizing a function at the expense of the overall company benefits.

Top 2020 Supply Chain Strategy Posts from the Supply Chain Link Blog

Over the past year, the Arkieva Supply Chain Link Blog provided thought leadership and informative posts on supply chain strategy tips, trends, and news. Here we have compiled a list of our popular supply chain posts from 2020.

Top Ten Holiday Wishes for Directors of “Extended” Supply Chain

With the holiday season, everyone is making their wish list and checking it twice. Here are some ideas to add to any director of supply chain's wish list.

Technology Investment: Lessons from Past Gurus – Importance of Seasoning

For a new technology to be successful it requires the correct seasoning which requires time in the trenches. This blog captures lessons from two past gurus.

Retail Planning – Is It Time For A Change??

Isn’t the goal of a successful retailer to give the customer what they want, when they want it? And isn’t today’s customer changing their mind on what they want quicker than ever? Quick trend changes are driven by this customer and retailers must be flexible to survive...

COVID Vaccine Logistics: Helpful Lessons from Complex Manufacturing

Today we will discuss a few of the logistics challenges from the perspective of an industry expert with lots of time in the trenches. Arkieva is ready to help Delaware.

Data Science Without Modeling Impact is a Path to Disaster – Simulation to Explore the Impact of Group Size on COVID-19 Spread

In this blog post, we will briefly review some examples of being “COVID-19 adrift” with just data and then focus on the primary task – demonstrating how modeling can be used to understand the impact of group size on COVID-19 spread.

Data Science Tools of the Trade: Monte Carlo Computer Simulation

Monte Carlo Discrete Event Computer Simulation is a particularly powerful and flexible “tool of the trade” for a wide range of challenges in supply chain and operations management. This blog provides some basics on MCDECS, the next blog will use MCDECS to explain why limiting the size of a gathering helps reduce the spread of COVID-19.

Investing in SCM Technology: Sense and Respond – A Vision from A Long Time Ago in A Galaxy Far, Far Away

Having a vision of the future is important to help coordinate SCM initiatives towards the “global good” – but having a vision is worthless without effective work in the trenches. In fact, a far better vision is “sense and respond” SAR which moves an organization from a big bang paradigm periodic driven approach that currently dominates SCM even in best in class organizations to an “as needed” basis.

SCM Technology Investment – INFORMS Provides Critical Information for Success

Before the current set of analytics and SCM experts, it was the OR/MS profession that drove the development and successful application of analytic and data methods to improve supply chain performance. INFORMS continues to lead in the ongoing challenge of more intelligent and responsive supply chains. In this blog, we will point out some keynote addresses from the current meeting of relevance to successful SCM technology investments.

Investing in SCM Technology: 6 Hints for Success – From a Long Time Ago in a Galaxy Far, Far Away

“Chaos, complexity, and uncertainty” often victimize an organization’s supply chain outstripping the ability of spreadsheet-based tools to respond intelligently. Sounds like 2020? In fact, this comes from one of the original Jedi Knights Dr. Harlan Crowder in a 1997 paper titled “Helpful Hints for OR/MS Consultants”. The purpose of this blog is to revisit this paper since the hints for success are as relevant now as they were then.

Investing in SCM Technology: Vision and Trenches – Lessons for a Successful Journey

The purpose of a vision in this journey is to create a focus on the implementation of decision technology as tools to overcome inherent organizational cognitive limitations of bounded rationality and uncertainty bias to improve SCM. This blog provides some critical lessons to protect a firm’s investment in technology.

5 Things to Consider When Starting Your Supply Chain Digital Transformation Journey

Digital Transformation is a popular term being used in today’s supply chain world. This can mean different things for your organization based on your company’s maturity. In this blog, you will learn the five key points to consider in a supply chain transformation journey.

Insight from Applied Statisticians for Forecasting: Is It Worth the Effort and the Mirage of Random Variation?

In this blog, we will illustrate through an example of these potential pitfalls (unanchored, random variation, and narrow metrics) and potential negative impact on a firm.

MAD versus Standard Deviation for a Uniform Distribution

In my last post, I talked about the relationship between the mean absolute deviation (MAD) and standard deviation (STDEV) for a normal distribution. Apparently, many people had never seen the math behind it, and I got questions about the same relationship for the case where the demand was not normally distributed.

Demand Versus Predict Variability – Avoiding a Paint by Numbers Disaster

In this blog, we will focus on protecting your investment. The example involves demand variability versus prediction variability and its impact on inventory policy and operational efficiencies. It is loosely based on a real situation from the trenches.

Lessons for COVID-19 and Supply Chain Management – Six Months Later

Over the past six months, significant progress has been made in understanding COVID-19 and reducing its health and economic impact. In this blog, we will not rehash this information, but to identify open issues in handling the current challenge of tackling COVID-19 and relate this to the challenge of managing supply chains.

Invest in Supply Chain Management Technology: Efficiency Assessment

When and how to invest in supply chain management technology is a critical question for all firms that is not a one-time question, but ongoing...

Invest in Supply Chain Management Technology: Survival and Ability to Respond to Emerging Challenges

When and how to invest in supply chain management technology is a critical question for all firms that is not a one-time question but ongoing. This blog will observe the real business value is “survival and responsiveness” and elaborate on the challenges with this evaluation.

Can You Make the Case For Supply Chain Technology Investment?

The right technology can provide a solution to maintaining optimal supply chain planning, but how can you justify the investment?

Machine Learning and Data Science Tools of the Trade: First-Order Difference

There are a number of data analysis “tools of the trade” that have proven effective in exploring data to get it to tell a story. One such method is the first-order difference (FOD). The purpose of this blog is to provide an overview of FOD with respect to profiling demand history.

Machine Learning: Optimization and Community Intelligence – A Wiser Forecasting

Learn the importance of advanced optimization for statistics (AOS) even for simple methods such as exponential smoothing and the importance of community intelligence.

Machine Learning and AI: Profiling Demand History – A Wiser Forecasting

In the simple version of supply chain management (SCM) the goal for demand forecasting in the tactical decision tier is prediction accuracy. In the wiser version, the purpose is expanded to include an understanding of your demand (demand profiling)...

Relationship Between MAD and Standard Deviation for a Normally Distributed Random Variable

A colleague and I were talking recently, and the conversation turned to what is the relationship between Mean Absolute Deviation (MAD) and the Standard Deviation (STDEV). In this post, I will explain to you the math behind that approximation, which by the way, only applies to normal distributions.

Inventory Management – Navigating the Trenches Without Losing Sight of the Big Picture

Inventory comes in many forms and flavors; it is the critical element of supply chains that enable a firm to respond quickly and take advantage of scale. However, managing inventory is one of the most...

Inventory Management: Avoiding Data Driven Disasters – Targets and Monitoring

Inventory management (IM) is a critical component of any successful organization where the mechanics of measuring and monitoring inventory involve KPIs, dashboards, and data science...

The Dual Reality of Inventory Management (IM): Stand Alone and Central Planning – Avoiding Data Driven Disasters

This blog will provide some basic information on CPIM to balance the SAIM focus of these webinars and most importantly position the two so that the oversight of inventory is coordinated.

Executive Perceptions of Machine Learning and Data Anomalies

The chatter about Artificial Intelligence’s (AI) and its recent companion, machine learning (ML) is ever-present. In a wide range of economic activities, AI/ML methods are now standard practice...

Supply Chain Management – Autonomous is Far Away and Resiliency is Needed Now

Over the past few years, the chatter about the role of AI to “optimize” supply chain has been almost endless. Some of the material is great, other is hype, some conjecture, and in most cases, we will not know the impact...

Statistical Forensics: Manipulating Probabilities to Determine the Real Risk From Viruses

The risk of viruses is often a topic of conversation in current times. One of the dominant questions at social gatherings is - what is a bigger risk (defined as serious illness) this fall and winter: regular virus (REGVIR) or COVID-19...

Optimization and Effective Use of Space – COVID-19 Challenges

For most involved in Supply Chain Management, optimization is viewed as one of the three primary methods to create a supply or central plan that matches or balances assets with demand. Historically effective use of space involved minimizing unused space or maximizing revenue from a fixed amount of space. COVID-19 has upset the social order.

Avoiding Data Driven Disasters – Operations Management (OM) To The Rescue

If you are thinking “machine learning and AI” will save you from data disasters – think again as the pandemic behavior is playing havoc with machine learning models.

Statistical Forensics – The Danger of Being Data and Not Operations Management Driven

As previously discussed, being only data-driven can be a road to disaster for COVID-19 or supply chain management. To avoid this disaster requires skill sets from operations management (OM). In this blog we demonstrate that the probability a person actually has COVID-19 antibodies depends heavily on other factors besides the “raw data” of the test results.

COVID-19 & SCM – Importance of Operations Management to Overcome the Limitations of Data-Driven

An often-heard theme in supply chain management (SCM) and COVID-19 is “data-driven” – being data-driven is the path to success. For COVID-19 “science-driven” is often said in the same sentence. For SCM demand or customer-driven replaces “science”. This blog will point out a few examples in the COVID-19 challenge demonstrating COVID-19 is an OM challenge.

Demand Management’s Partner in Crime – Central Planning

Arguably the two most important core components of managing the supply chain or demand-supply network are demand management (DM) and Central Planning (CP). CP is sometimes referred to as master planning or supply planning.

Supply Chain Challenges in Turbulent Times – The Importance of Preparedness and Responsiveness

The current COVID-19 situation highlights the supply chain management challenges in any turbulent time. In this blog we identify five key points: preparedness, larger good, anticipate, and not react to events, responsiveness, and an intelligent stochastic estimate of demand.

Lessons for COVID-19 and Supply Chain Management Models

For those that work regularly in the supply chain or managing the demand-supply network (DSN) models are commonplace to help with similar questions. This blog will provide some basics about models that all will find helpful...

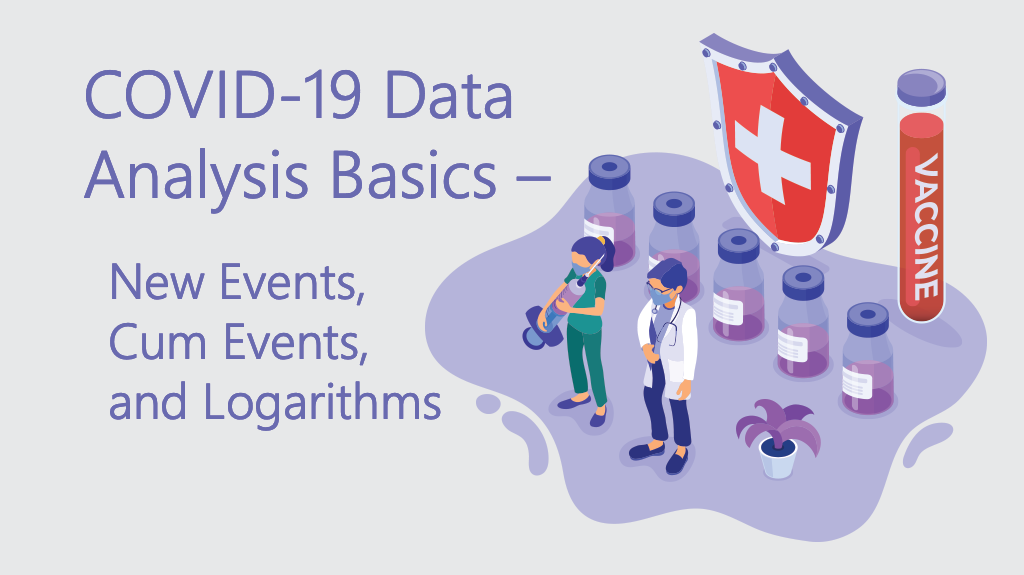

COVID-19 Data Analysis Basics – Taking the Mystery Out of Smoothing Daily Counts

We see graphs of COVID-19 events on a regular basis. One of the most common is a bar chart for daily new events (COVID-19 cases, hospitalizations, deaths). Recently in presentations, smoothing methods used to overcome limitations is presenting the raw daily data. This blog will take some of the mystery out of smoothing methods.

COVID-19 Taking the Mystery Out of the APEX Curve and Some Basics on Restoring “Normal”

This blog provides some basic information on the curve, relates statistical concepts to policy and actions, and examines policy options for a safe restart relating them to the APEX curve. There are three essential groups of action to begin a safe restart: testing, detailed understanding of the impact of mitigation actions, and the ability to do detailed tracking.

Some COVID-19 Data Analysis Basics – New Events, Cumulative Events, and Logarithms

We see graphs of COVID-19 events on a regular basis these days. Two common ones are bar charts for daily new events (COVID-19 cases, hospitalizations, deaths) and the “sweeping curve” to capture a cumulative number of events. Additionally, log transformations are mentioned. The purpose of this blog is to shed a bit of light on these curves and the role of the log transformation.

Lessons From the Operating Curve for the Dual Government COVID-19 Objectives: Reopen the Economy and Eliminate COVID-19

There is plenty of material being written and posted on the challenges, estimating the growth in COVID19 incidences, and thoughts about the economy. The purpose of this is to pull from experiences in the trenches in shifting OPCURVE to provide some guidance on actions to take to help the nation achieve both critical goals.

Some Basics on the Value of S Curves and Market Adoption of a New Product

An ongoing challenge for any firm is estimating demand for new products. This is especially true when the product has new technology or is replacing an existing product and the additional function in the new product is limited. Often a mathematical construct called an S curve is helpful. This blog provides an overview of S curves and why they can be helpful.

Taking the Mystery Out of the Rapid Growth of COVID-19 and the Purpose of Social Distancing – Some Basics for Octogenarians

The spread of the COVID19 virus is a major concern of everyone. Typically, two critical questions are being asked: why it seemed to grow so quickly over the last few weeks and what is the impact of social distancing. This blog provides a kitchen table explanation of “rapid growth” and how social distancing might dampen growth.

Conditional Probability Made Easy – Heart of Machine Learning

Probabilities are persuasive in supply chains and analytic methods – especially in machine learning where conditional probability is a dominant underlying structure that makes or breaks the success of an application. In this blog, we will learn how to take the mystery out of the term ‘conditional probability’.

Safety Stock for Raw Materials – A View from the Trenches and Importance of Community Intelligence

A common question is how to best manage safety stock for critical raw materials that are critical to the production of the exit product...

What-If Scenario Planning – Part 3

Picking up from where I left off in my previous blog, I will look at a few more scenarios in both short and long terms in this blog. Even though Brexit is the theme for these scenarios, the underlying principles apply to any situation with uncertainty in supply planning.

Optimization and Central Planning: Compass or Advanced Navigation

Two ongoing questions are: (1) when an organization migrates from an Excel-based central/supply/master plan is it best to go to a rule-based method or an optimization-based method and (2) is optimization a compass that identifies true north or is it an advanced navigation system. This blog outlines my view and alternative views on each question.

“Optimized” Inventory Forecasting a Co-Product of Optimized Central Planning

In a recent blog on Inventory Forecasting the core challenges and business importance of estimating inventory are outlined. A projected inventory position across time (plan) is a natural co-product of most central or master planning models that match assets with the demand to create a projected supply line linked to demand.

Coronavirus: A Substantial Supply Chain Interruption – The Importance of Digital Supply Chain

The tragic outbreak of the Coronavirus has again demonstrated the need for ever vigilant health care services and fast response. It has demonstrated that supply chain interruptions from a manufacturing excursion to a port strike to an infectious disease outbreak require two actions from any firm: preparation and response.

Data Science | Analytics Basics: The Difference Between Quantitative and Qualitative Data

In this blog, you will learn some basic guidelines to determine if the data is quantitative or qualitative with a focus on...

What is Inventory Forecasting & Why Does Your Business Need It?

Inventory Forecasting is the process in which the historical sales data, historical purchasing data, current demand planning, planned production, and distribution resource plan data are used for predicting inventory levels in a future time period.

In Search of the Dashboard You Deserve

Most software packages show current views of current forecasts, sales, production, and inventory. But what if you wanted visibility of the underlying trends, changes, patterns in all systems...

How Can What-If Scenario Planning Help Plan for Brexit?

In my previous blog, I addressed how what-if analysis can help supply chains when faced with uncertainty. This blog is an attempt to delve into some specific what-if scenarios that could arise due to Brexit.

Is your Supply Chain geared-up for this Holiday Season?

For businesses, it’s a great opportunity to cash in on the seasonal spike in customer demand. However, every year it also poses a unique situation with equal challenges along with the opportunities.

Shutdown Days & Demand Patterns

Shutdown days are either planned well in advance or inadvertent and unwelcome manufacturing excursion- this is a factory issue, not a demand issue. The answer is simple...

Lots of Zeroes? Basic Guidelines to Managing Intermittent Demand – Part 2

In Part 1 of this blog, we closed with the following question: “OK, intermittent demand creates a challenge, but I still need a demand estimate, what do I do!” Below we will provide an answer, but with a different orientation that begins with the question: “what is the purpose of the demand estimate?”

RCCP versus MPS –historic terms and a path to inadequate organizational performance

Where did the terms RCCP and MPS come from? Reading the recent blog “RCCP versus MPS – Can They Be Connected?” it struck me whether this question represents the current best in class or do they represent old terms as well as an old way of thinking that should not be the end goal of an organization any more when it comes to supply chain planning.

Supply Chain Planning in the Times of a Trade War

US and China have been at the forefront of a tariff battle that’s been going on for close to a year and a half now. Given the economic might of these two nations, the tariffs by both sides have not only affected them but have also had a domino effect on several other countries across continents.

IOT and Digital Enterprise Move Over – the next wave: Community Intelligence

Community Intelligence synchronizes the use of technologies in a manner that is focused on closing gaps in critical decision-making processes in the ongoing journey of more intelligent supply chains to improve organizational performance.

3 Essential Steps for Setting Supply Chain Digital Transformation Goals

Building the business case for change is crucial to compel transformation at a leadership and organizational level. Before you start any transformation project it is important to understand the why, what, and how and articulate a clear vision and path of the future state.

RCCP versus MPS – Can They Be Connected?

Master Production Scheduling (MPS) plans for items that are independent (or direct) demand. Independent Demand is a demand that comes from Sales Orders, Service Orders, or forecasts on end items, i.e., items that we sell to customers. In RCCP, the principle assumption is that family-level assumptions are good approximations for the SKU level detail and the change in the mix will not have a big impact on the capacity projection.

Probabilistic Forecasting and Confidence Intervals

Historically, most of the key planning and computational activities (models, time series, machine learning, and other analytics) that support extended supply chain management (SCM) are “deterministic models”.

Forecasting Lessons From Popeye Chicken Sandwich Stockouts

Though social media could drive up the brand of a company, it can also cause big disruptions in the supply chain operations of a company. A great example that happened recently is where Popeyes Louisiana Kitchen chain ran completely out of chicken sandwiches.

Business Forecasting Lessons From Hurricanes

With each storm, there comes a bevy of forecasts put out by different computer models. These forecasts begin about 10 days out and change as the storm gets closer and closer. This blog tries to extract some learnings from this process of forecasting.

Top 7 Benefits of System driven Inventory Projections

Scientific and system-driven Inventory Projection facilitates a quick decision-making process and enables a prompt analysis of alternative what-if scenarios. The following are the top 7 benefits of system driven inventory projection.

Effect of Shutdowns (or Other Supply Disruptions) on Demand Variability

When trying to forecast demand for the future, it is important to understand the variability in the underlying dataset.

Make Demand Segmentation Effective With The Use Of Exception Management

There is no doubt that demand segmentation can help you bring clarity to demand planning and the overall supply chain planning process and lead to far superior results in terms of various supply chain metrics. At the core of segmentation is the understanding that one size will not fit all.

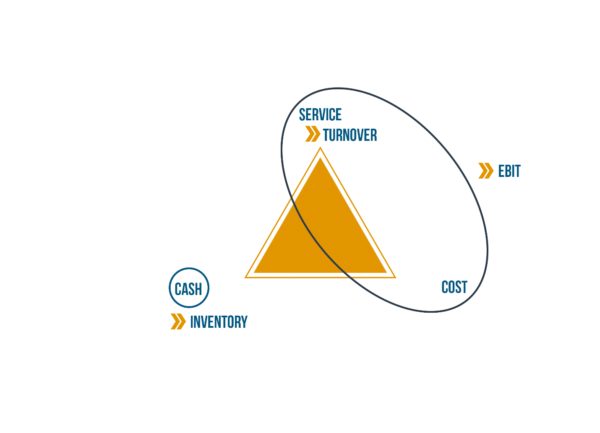

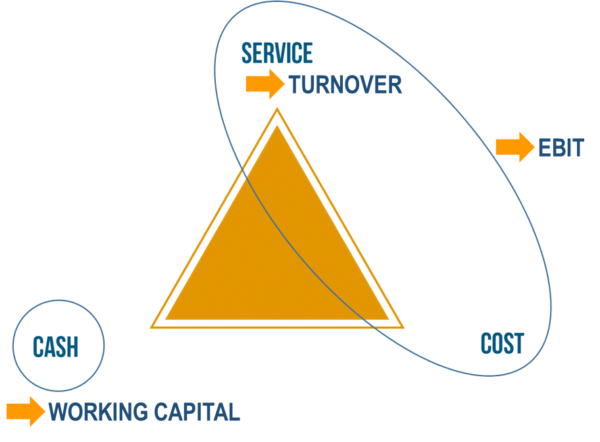

Impact of right-sizing inventory on EBITDA

Supply chain planning projects are often approved on the back of the promise of lower inventory levels. In a recent conversation, I was asked a more nuanced question: whether right-sizing inventory via better supply chain planning improves earnings before interest, tax, depreciation, and amortization (EBITDA). This blog tries to address this question.

10 Ways to Create Supply Chain Risk Buffers for Economic Uncertainties

Use this guide to identify 10 key elements for evaluating your existing supply chain risk management strategies.

How Do You Create the Right Inventory Balance?

Striking the balance between overstocking and understocking should not always be a guessing game.

Forecasting with Returns

Should we combine the positive numbers and the negative numbers as we approach the essential business of forecasting future demand? Let us think this through.

How do you create a more productive dashboard with your planning system?

What’s the difference between creating a dashboard you want and the one you need? Focus and productivity. Here are few planning system dashboard tips to help increase productivity.

What is a Supply Chain Digital Transformation?

Gartner defines Digital business transformation as “the process of exploiting digital technologies and supporting capabilities

Discover Why Arkieva is Named As a Leader in The 2019 Gartner Magic Quadrant for Sales and Operations Planning System of Differentiation

We are pleased to announce that due to the amazing support of Arkieva customers, Arkieva has been named as Leader in the 2019 Magic Quadrant for Sales and Operations Planning (S&OP) System of Differentiation (SOD).

Q&A: How is Linde Optimizing Operations with a Supply Chain Digital Twin?

Arkieva Customer, Linde PLC, is a leading supplier of industrial gases in the world. Linde has transformed its network optimization processes by creating a digital twin of its integrated supply chain with Arkieva. I sat down with Richard Wallington, Global Head of Bulk Supply Chain at Linde to find out more.

Key Supply Chain Digital Transformation Pitfalls to Avoid

Supply Chain Digital transformation has the potential to be, for no better words, transformative; when done right, a transformation can enable your business to reap significant, and well-documented, benefits. On the other hand, Supply Chain Digital Transformation if executed poorly cost companies millions, go on for years, fail to deliver expected or any benefits, and ultimately end up costing some CEO and CIO their jobs.

Is Your Supply Chain Ready for Industry 4.0?

From the move from centralization to decentralization, a cobot world, and smart factories, Industry 4.0 is here and it’s happening fast. Are you ready?

Statistical Modeling VS Machine Learning

Sometimes statistical prediction is confused with statistical forecasting. Forecasting can be considered a prediction model but not all prediction models can be considered forecast models.

I created an Out of Stock Alerting Process with Excel. Here’s What Happened.

I experienced first-hand the limitations of automating out of stock alerts using Excel. Here’s a real-life example of the out of stock process that I created.

Demand Segmentation Starter Guide

Use this comprehensive guide to get started with your product-customer demand segmentation analysis process.

How Does a Supply Chain Planning System Aggregate and Disaggregate Data?

Planners in certain industries such as the consumer-packaged goods (CPG) prefer updating forecasts at an aggregate level but would also sometimes want to lock values at the detail level to prevent disaggregation to a specific combination. How is it done? A planning system is expected to present correct data to the planner at whatever level it is being looked at.

How to Measure Forecast Errors in Intermittent Demand Forecasting

Stop using traditional forecast accuracy metrics to measure forecast for sporadic demand patterns. Use this method instead.

Your Data is Only as Good as How You Visualize It

Are you avoiding these common data visualization pitfalls during your S&OP meetings?

Challenges with Excel When Building a Demand Planning Process

Gartner estimates that by 2020, 60% of revenue in supply chain dependent industries will be driven by digital business.

Who Should Own the Demand Management Process?

Who should take ownership of the demand management process within the organization? Is it Sales and Marketing?

Supply Chain Best Practices from 10 Leading Companies

Here’s a quick overview of supply chain best practices from 10 leading companies from the 2018 Drucker Institute Ranking.

Top 10 Demand Planning Metrics You Should Have on Your Dashboard [Infographic]

To stay ahead of the curve, effective demand planners must track the right metrics that can help curtail possible demand planning issues ahead of time.

How to Forecast Demand for New Products

Organizations need to regularly upgrade their products and launch new products to stay competitive and grow their businesses. However, a new product launch poses a totally new challenge – new product forecasting.

12 Days of Inventory Optimization

One of my favorite Holiday songs growing up was “The 12 Days of Christmas.” There was something about Christmas having 12 days that put me in the holiday spirit.

Thieves in the Temple – Errors in the Planning-Execution System

Here’s a quick look at how to identify and fix errors in planning execution systems.

Selecting the Appropriate Forecasting Method

Selecting the right forecasting methods can be highly critical in how accurate your forecasts are. Unfortunately, there isn’t a golden ticket to forecasting which can essentially ensure accuracy. While the best-fit forecasting method is dependent on a business’ specific situation, understanding the types of forecasting methods can aid in your decision-making.

Portfolio Pruning for Product Managers

Do others challenge your expanding portfolio or complicated offering? Need a portfolio pruning process or policy to keep a manageable inventory? Want to take the drama out of keeping or deleting products?

Is Community Intelligence the Next AI Wave?

Most of us have had some exposure to the “AI Awakening” wave that has emerged over the past few years. Of particular interest to Arkieva and its customers is how this “new technology” integrates with the ongoing journey of creating more intelligent supply chain decision-making process to improve organizational performance.

Demand Forecasting Analytical Methods: Fit Vs. Predict

How to determine when to use a best-fit analysis and when to use prediction techniques for demand forecasting analysis.

Why is Demand Forecasting important for effective Supply Chain Management?

Demand forecasting forms an essential component of the supply chain process. It’s the driver for almost all supply chain related decisions. While demand forecasting is undeniably important, it’s also one of the most difficult aspects of supply chain planning.

Using Demand Planning Statistical Models to Enhance Your Sales Forecasts

How to use demand planning statistical models to enhance the value of your sales input during the forecasting process.

Creating Detailed Customer Order Allocation Data for Yearly Volume Contracts

A guide on how to improve material planning using a more detailed volume allocation of customer orders. It is a common business practice to write up yearly contracts for the volume. Very often, this is done to extend volume discounts to the customer. That is obviously a benefit to the customer. The supplier benefits by knowing how much to budget for in terms of production through the year. They can also count on the revenue coming in.

Outgrowing Excel? Here’s How to Create a Centralized Demand Planning Process

Demand Planning directly affects the business financial plan, pricing, capex decisions, customer segmentation and resource allocation. Considering the criticality and implication of this process, Demand Planners and Managers need to continually evaluate their current Demand Planning process and ensure that the Demand Plan generated is holistic, relevant and timely.

[Infographic] 8 Traits of a Highly Successful Demand Planner

Here's a quick visual aid on some of the key attributes of a successful demand planner.

Everything You Need to Know About Demand Forecasting

What is Demand Forecasting? Demand Forecasting is the process in which the historical sales data is used to develop an estimate of expected forecast of customer demand.

A Six-Step Process for Demystifying Your Safety Stock Process

Do others challenge your safety stock selections? Are you in need of a safety stock process or policy? Want to take the drama out of your safety stocks? Use this collaborative six-step process to demystify your safety stock process and a create buy-in.

Effect of Customer Order Lead Time on Safety Stocks

What's the effect of customer order lead time in inventory management and safety stock calculations?

How to Build a Collaborative Global Demand Planning Process

How global businesses can build a collaborative demand planning process

ABC Segmentation for Inventory Management

A look at how you can use product and customer ABC segmentation for Inventory management.

Using the Power of Maps to Enhance Your Supply Chain Visibility

Mapping makes it easier to identify patterns and understand your data in a way that's not readily available using a table or a graph. Here's how you can use different types of maps to enhance your supply chain visibility.

Demand Management Best Practices

Is demand management illusively complex? Here's a look at some best practices in demand management and characterization.

7 Must-Attend Sessions at The Gartner Supply Chain Executive Conference

We are thrilled about presenting a session with Arkieva customer — Lush Handmade Cosmetics. The session that focuses on how Lush delivers a unique brand experience also discusses how effective demand planning solutions help with creating that experience. Last year we created the 2017 Gartner Supply Chain Conference list of Must-Attend Sessions. To continue along that tradition, here is the list of Must-Attend sessions at the Gartner Supply Chain Conference this year.

4 Things to Know When Building a Demand-driven Supply Chain Management Process