Recently someone asked me: What would happen if one were to increase the frequency of replenishment in a retail store? Would the inventory investment go up or down? What about the service level (SL)? This person was interested in a mathematical answer, complete with formulas.

Let Us Explain the Context First

In many retail stores in the US, replenishment is done by the vendor using the Direct Store Delivery (DSD) model. Typically, the vendor would show up at the store every night and replenish the shelves. In this model, the maximum delay time between replenishments is 1 day; hence, the lead time is also 1 day. The amount of replenishment would depend on two things:

- The amount of shelf space allocated to that product and/or vendor

- The amount of product consumed from the time of the last replenishment (AKA during the last cycle)

As an example, if the previously negotiated shelf space allows for 150 units of the product and 120 units were sold in the last cycle, then there would be 30 units still left in inventory. The vendor personnel would replenish 150-30 = 120 units. If, on the other hand, all 150 units had been sold, then the shelf would be empty (a stock out) and the vendor personnel would replenish 150 units.

- What happens to the lead time if the replenishment frequency is doubled?

- The lead time is halved.

- What happens to the lead time if the replenishment frequency is halved?

- The lead time is doubled.

Now Let Us Do a Thought Experiment

What if we keep doubling the replenishment frequency? This would keep cutting the lead time in half. Eventually, we would reach a point where we would be replenishing instantaneously. In other words, the lead time would be 0. In this case, we would achieve a 100% service level with 0 inventory.

Let us also go the other way. What if we keep halving the replenishment frequency? This would keep doubling the lead time. If we keep doing this over and over, eventually our lead time would approach infinity. In this case, it is easy to see that maintaining a good service level will be very difficult and would require a lot (infinite amount) of inventory.

Admittedly, both zero lead time and infinite lead time do not seem practical. However, intuitively, it seems clear that if we wanted to keep the same service level, then:

- Increasing the frequency should decrease the inventory investment

- Decreasing the frequency should increase the inventory investment

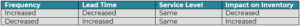

The tables below summarize the two ways of thinking. The inventory decrease or increase will come from both a reduction in cycle stock as well as safety stock.

To maintain the same service level:

If, on the other hand, one maintained the same inventory level, then:

Finally, Let Us Look at it in Terms of the Math, Starting with the Safety Stock (SS):

- If σD represents the daily demand standard deviation, then the standard deviation of the total demands over L days would be = σD*√L.

If one ignores the variability in lead time, supply amount, etc., then the safety stock can be defined as:

- Original SS = Z-score * σLD*√L, where L is the lead time and Z-score is the multiplier associated with the desired service level.

Similarly, the standard deviation over L/2 days would be:

- σ(L/2)(D)

- = σD*√(L/2)

- = σD*√L*(1/√2)

- = σLD*(1/√2)

- = 0.707* σLD

Thus, if the lead time is halved (which is what happens when replenishment frequency is doubled), then the new SS is:

- New SS = Z-score* σD *√(L/2)

For the same service level, the Z-score will not change. Thus:

- New SS = (1/√2) * Original SS = 0.707 * Original SS

So, if the replenishment frequency is doubled, one would need 30% less inventory as safety stock assuming the desired service level does not change. By similar math, one can also see that if the replenishment frequency is halved, one would need 41% more inventory as safety stock.

Since the original question was related to service levels, we should only focus on the portion related to safety stocks. To maintain the same service level in the case when the replenishment frequency is doubled, the investment in safety stock can be reduced by 30% (1-(1/√2)). OR, if the business decides to keep the inventory unchanged, their customers should experience higher service level.

But why stop at safety stock. Let us proceed further and look at the cycle stock (CS):

- If μD represents the daily average demand, then the average over L days would be μD * L

- Therefore, Original CS = μD * L

- New CS = μD * (L/2) = 0.5 * Original CS

Thus, if the replenishment frequency is doubled, it will result in half the cycle stock. Similarly, if the replenishment frequency is halved, it will result in double the cycle stock.

Let Us Summarize Now

If a vendor supplying to a store wishes to provide more frequent replenishments at a higher cost (logistics, more drivers, etc.) to herself, is that a worthwhile investment? As we saw above in the example above of doubling the frequency, she would need half the cycle stock and 70% of the original safety stock. This means she could further save money by renting a smaller shelf space in the store. By comparing the costs associated with the higher frequency of investment to all the savings (cycle stock reduction, safety stock reduction, shelf space rent reduction), she can make an informed decision.