2017 Supply chain productivity and prioritization tips for supply chain planners.

Every morning, a supply chain planner must make this decision; “what should I work on today?” In a supply chain of any reasonable complexity, this question can easily be answered with the corresponding fire of the day. On any given day, a supply chain is going to have many moving parts, and just by the law of averages, some part will be in a breakdown mode. The urgency needed to deal with these problems could start from a ‘red-hot-deal-with-it-now’ to just another piece of information that one needs to consider. With today’s software technologies, it is possible to create alerts and dashboards warning planners about potential disruptions in the supply chain.

The alerts today are typically designed to scream for attention should the situation so demand. A very popular design uses a red-yellow-green color scheme to immediately draw the attention towards the red and bring the user to a stop so they can deal with that situation.

Trending: Top 2016 Supply Chain Strategy Posts from the Supply Chain Link Blog

If your job is the equivalent of a firefighter in your organization, then by all means, you should arrange these alerts on your computer screen, and you could even further enhance the ‘alerting’ mechanism by sending email alerts to your mailbox and text messages to your phone. However, if your job is to be a planner, and especially supply chain planner, how should you behave?

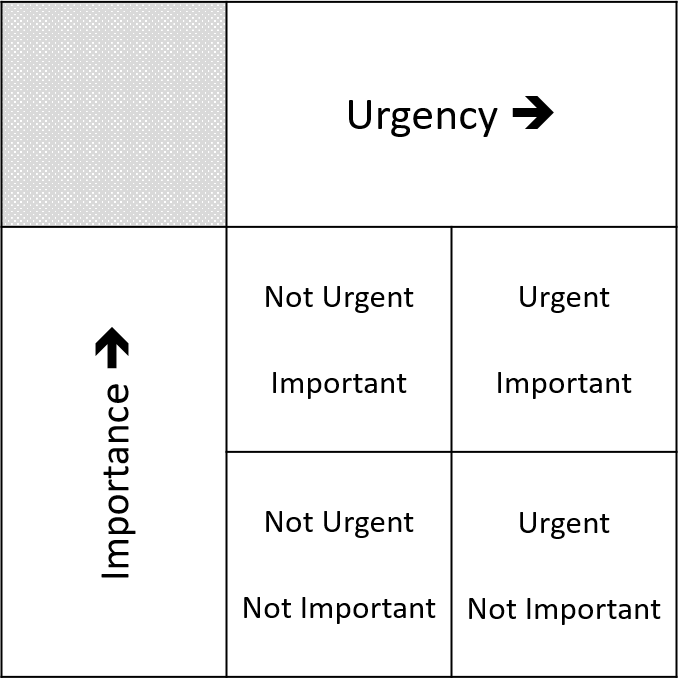

Steven Covey’s famous book, ‘The 7 Habits of Highly Effective People’, has this nice graphic that explains prioritization.

Based on this graphic, Mr. Covey made the point that most people focus too much time on what is urgent. If it happens to be important as well, then that is great. But sometimes, the urgent and not so important can take away time from the important but not urgent activities. He provides several examples of this in the book.

Read Also: Customer-Centric Supply Chain Planning: The Difference is in the Details

When it comes to planning activities, the alerts raise the urgency flag on areas they are alerting about. Thus, they bring more focus to the urgent. If the alerts are poorly designed or are simply too many in number, very often, they will subtly encourage the planners to deal with the urgent. If the planner is not very disciplined, he or she may make the mistake of ignoring important but not urgent activities very often. Anyone who has attended an S&OP meeting could attest to the tendency to let the alerts drive the S&OP meetings.

Let me share an example of this from my experience. When I got my first smartphone, I had the setting turned on so that I would get a little ping each time a new email arrived. After each ping, I would dutifully check my phone. Often, I would respond to that email, regardless of how important it was. As I was doing this, I would not realize that it was at the expense of what I was working on at that moment. So, if I was in the middle of writing a blog piece, I was allowing the ping to interrupt my train of thought and was delaying the important for the urgent, only because of the alert (ping). (Sometimes I would check my phone even without a ping, but that is a whole other topic).

In the supply chain planning world, the real job is to plan while learning from the past and the present. Presumably, the near-term problems are mere distractions (although, admittedly, not all of them are). So, how does a planner plan his time, so he or she focusses on the right things? The answer in my mind is in designing a process.

Related: Can Supply Chain Planners Ignore ROI?

There are things that a planner will do because they are on the planning calendar. Presumably, the calendar is well designed is full of important activities. Of course, near the due date, they also become urgent. A good process step is to weed out the non-important stuff or do them less often.

There are things that a planner will do because of an alert. A good alert will be both urgent and important. A good process step would weed out the bad alerts, as well as, improve the design of the alerts to make them into an early warning mechanism. (More on this topic in a future blog post.)

Finally, a good plan process would always reserve enough time for not urgent but important activities. An example could be time allocated to do a few what-if scenarios in each cycle or to do a root-cause analysis of recurring problems. Therefore, allowing some issues to be resolved before they become problems or before they reach the urgent step.

My suggestion to supply chain planners is to fully recognize and embrace that they are not the firefighters in the company, their job is to plan for the future. Frequently, this will require them to ignore some alerts. As a wise man once said: Sometimes, one must ignore near-term losses to get long-term gains.

Enjoyed this post? Subscribe here for email updates.