To optimize your supply chain, there is the need to look at the entire process, and not just the initial solution. Here’s an example of how.

Typically, the purpose of supply or central planning within the supply chain management process is to intelligently match current and future assets with current and future demand to best meet prioritized demand without violating physical and temporal constraints and create a “game plan” for the enterprise. Typically, the game plan has two components:

- A projected supply line linked to demand

- Synchronization of the activities of the firm typically through either starts and intermediary output targets

Over the last 20 years, suppliers of central planning engines (CPE) have focused on “optimizing” the initial solution applying mathematical methods to handle a wide range of demand priorities, use every “iota” of capacity, and make the best use of co-products. Overall there are real benefits to the approach – it can find solutions of value that would not otherwise be found and shift the curve.

Optimizing Your Supply Chain Planning Process

However, “optimizing” the initial plan is just one part of optimizing the entire solution which includes robust estimates of capacity and cycle time, a true understanding of the demand patterns, the process of building and “promoting” a plan to record, etc.

A firm that wants to be responsive must see the initial plan as the base and provide its planner the software tools to navigate and adapt the plan.

To enable the planner to easily identify what set of enterprise activities are linked together in what order to support an exit demand; try out alternatives including options to override capacity restrictions (which are just estimates); and “book” incremental modifications to the plan without “rerunning” the entire plan. It needs to provide its planners an environment that mimics making a small plan “manually” on a large whiteboard with the computational ability to manage large complex plans. That is answering the question – “how is this order being satisfied? And what if I do something different?”

Let’s look at the following example.

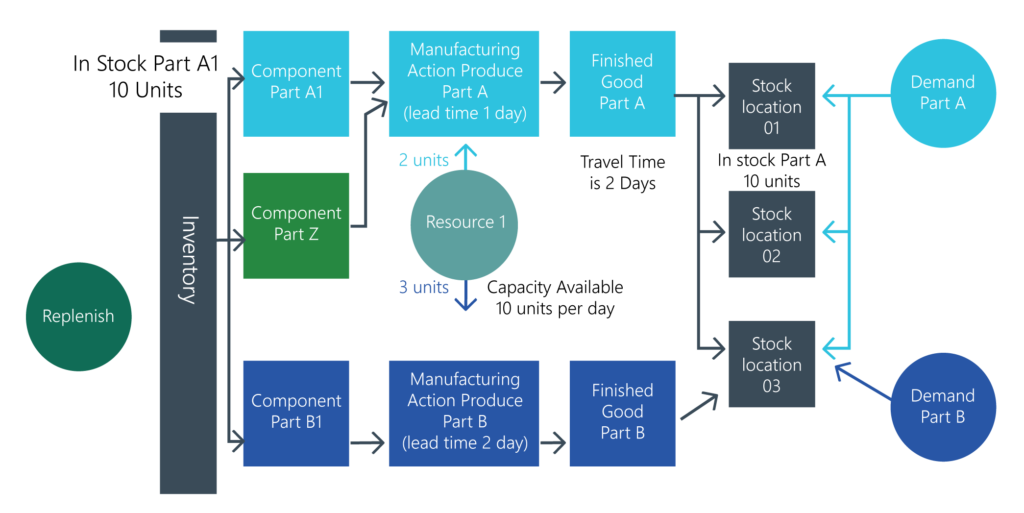

Figure 1: Example of Supply Chain

In this example (Figure 1) the firm produces two finished good parts (A and B). Part A consumes 1 unit of part A1, 1 unit of Part Z, and 2 units from Resource 1 with a lead or cycle time of 1 day. Part B consumes 1 unit of Part B1, 1 unit of Part Z, and 3 units from Resource 1 with a lead time of 2 days. Parts A1, B1, and Z are purchased in bulk from a vendor and stored in inventory on the manufacturing location. Once Part A is completed it is sent to one of the three stock locations. Part B is only stored in stock location 03. It takes 2 days to ship Part A to any of the three stock locations and 1 day to ship Part B to stock location 03. Transport time directly to a client typically takes 2 days. The firm has 10 units of Part A in inventory in stock location 01 and 10 units of part A1 in stock in the factory.

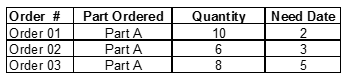

Assume the firm has three orders for Part A as follows:

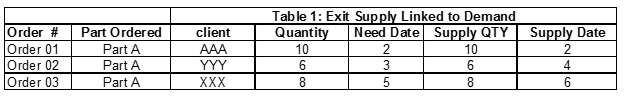

The output from a typical central planning engine solution provides summary information specific to each “player” in the solution, but little or no information about how these actions support meeting an order. For example:

-

- Table 1 tells the planner when the model projects each order will be met

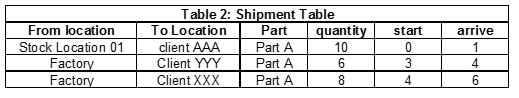

- Table 2 tells the planer information about each shipment

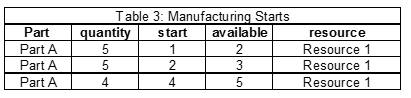

- Table 3 tells the planner about the production of Part A

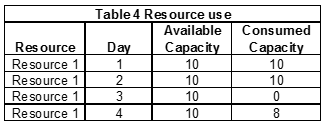

- Table 4 tells the planner about the use of Resource 1

This information by itself is useless in helping the planner navigate the linked sequence of activities in the firm being executed to support each order and identify possible actions to improve on-time delivery. The planning engine may have found an “optimal” solution, but there is nothing optimal to the planner who must answer some very reasonable questions by management and the client.

[Read More: Supply Chain Efficiency & Smart Planning Engines]Key Questions to answer to determine the optimal supply chain solution

What the planner needs are a tool(s) that enable him or her to create the following narrative.

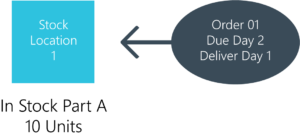

- Order 01 is met by allocating the 10 units in stock location 01 to this demand immediately enabling it to be met on time.

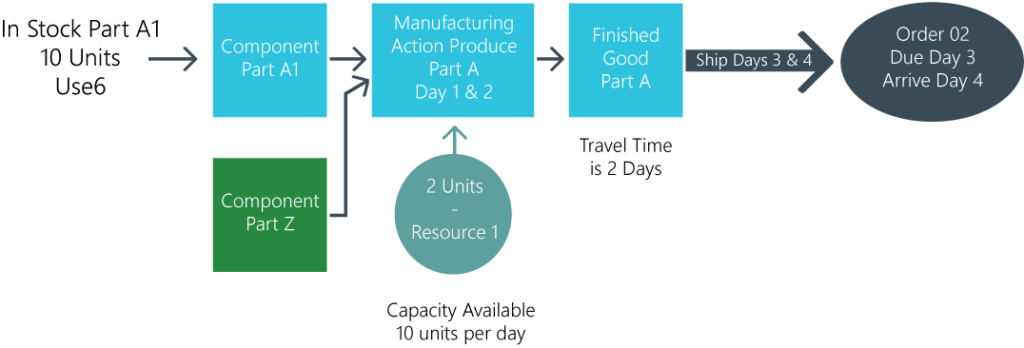

- The second order requires producing six new units of Part A at the manufacturing site and transporting them directly to the client. If the production starts immediately (on day 1), 5 units can be finished at the end of day 1. And the sixth unit on day 2 (since the capacity required is 2 units of Resource 1 per unit of Part A produced, and there are only 10 units of resource 1 available per day, this spills into day 2). If we assume the manufacturing location waits for all six units of Part A to be produced, and the units ship end of day 2; arriving at the customer on day 4 – one day beyond the need date. Then the production of these six units consumes 6 out of 10 of the units of Part A1 in stock.

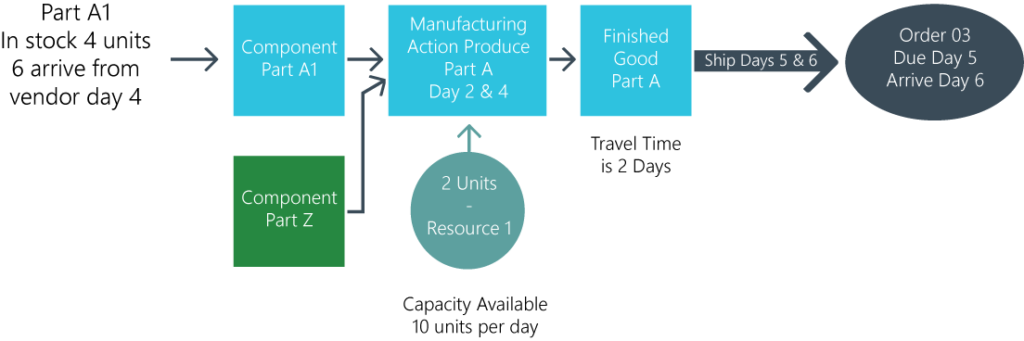

- The third order requires producing eight new units of Part A at the manufacturing site and transporting them directly to the client. This requires 4 units to be produced on day 2 and 4 units on day 3, shipping all 8 at the end of day 3, arriving to the client on Day 5. However, after producing 6-part A’s in support of order 02, there are only 4 units of Part A1 in inventory. Since it takes 3 days to replenish this inventory, the 4 units we want to produce on day 3, cannot be produced until day 4. Therefore, the client does not receive its 8 Part A’s until day 6.

Below are three simple graphics that begin to convey this story to the planner.

With this information, the planner can not only explain why the orders will be delivered late but identify opportunities to improve responsiveness.

[Read More: How to Determine the Best-Fit Plan with Supply Chain Optimization]For example:

- Free up two additional units of capacity on Resource 01 on day 1 so all the required production to support order 02 can be done on day 1.

- Expedite the delivery of additional units of Part A1, so the production to support order 03 can be completed on day 3.

It is essential for firms to “optimize” the entire process; which means better tools for planners to navigate and adapt the plan.Enjoyed this post? Subscribe or follow Arkieva on Linkedin, Twitter, and Facebook for blog updates.