Unpredictable, volatile, erratic. These words perfectly describe the supply chain of the 21st century. We’ve come a long way since the earliest industrial revolution with the advent of forecasting tools and technology to help align supply and demand. However, demand volatility remains a top challenge in supply chain management.

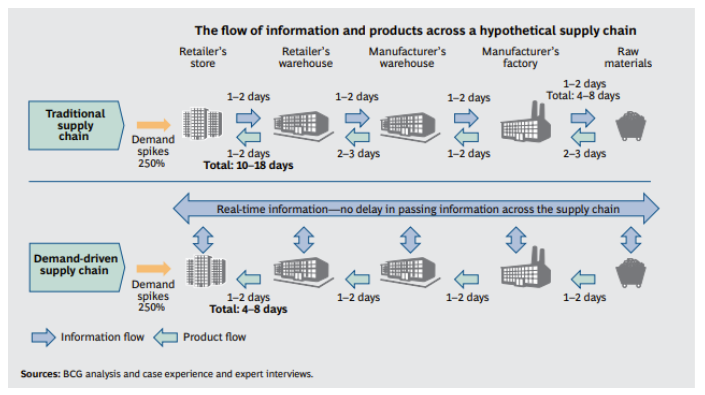

The onset of the Internet of Things (IoT), e-commerce hubs and the on-demand economy, had made it incredibly simple for consumers (B2B and B2C) to flip the state of demand overnight and increasingly difficult for industries to alleviate these sudden changes in supply efficiently. While suppliers usually have production aligned with their demand forecast, as soon as the actual demand differs, the lag time between the actual change and the detection of the change at different points in the supply chain causes production to be varied far from optimal conditions, leading to inventory shortages and excesses (Bullwhip effect).

So, what’s going wrong here?

The reasons for consumer demand changing are extensive, but the most common reason why industries can’t cope with such change is due to the lack of communication and informational analysis over the different tiers of the supply chain. Perspective is another factor. We usually tend to look at a supply chain top-down, from suppliers to production to transport/warehousing and finally to customers. Forecasts are obviously an integral part of the supply chain process, but it is constrained and overshadowed by the capabilities of the suppliers and production facilities, essentially the supplier push. What if we travel up the supply chain, begin at the demand side and work through the chain to the supply side based on demand data? This would create a Demand–Driven Supply Chain.

What is a Demand-driven Supply Chain?

A Demand-driven Supply Chain (DDSC) is defined as a supply chain management method focused on building supply chains in response to demand signals. The main force of DDSC is that it is driven by customer demand. In comparison with the traditional supply chain, DDSC uses the pull (Demand pull) technique. It gives the market opportunities to share more information and to collaborate with others in the supply chain.

A Demand-Driven Supply Chain is dependent on aligning all entities across the supply chain through information flows. A true DDSC can always adapt to the changing market conditions thereby maintaining or reducing inventory levels and reduce the invasive problem of expedited orders.

Source: Boston Consulting Group

[Instant Webinar: How to Avoid the Bullwhip Effect with B2B Demand Sensing]

Enjoyed this post? Subscribe or follow Arkieva on Linkedin, Twitter, and Facebook for blog updates.