Recently, I visited our office in Antwerp, Belgium. I was there to participate in the LogiChem conference with William (Billy) Duty, the Director of S&OP Center of Excellence at Momentive and an Arkieva client. As is often the case with my trips to Belgium, I ended up drinking more beer in my very short stay than I will drink the rest of the year. Only this time, the conversation with my colleague Philip De Rop turned towards the supply chain of Belgian beer. So, I thought about blogging about it.

Fair warning: The reader is hereby advised that this blog post might have more on Belgian beer than supply chain of Belgian Beer. Keep reading if you do not mind that tilt.

First of all, in Belgium, there are many kinds of beers. There are abbey beers, sour beers, lagers and pilsner beers and probably a lot more that I do not know. The most known abbey beers are Trappist beers which can only be brewed within the abbey walls. Trappists are one of the many religious orders in Belgium.

The Trappist beers are typically very good and they have other rules and regulations around them (scroll half way down the page here to see those rules). (As an aside, there is now a Trappist beer in the USA.) Many beers can also be sold with different alcohol content, starting at 5-6% and going as high as 11-12%.

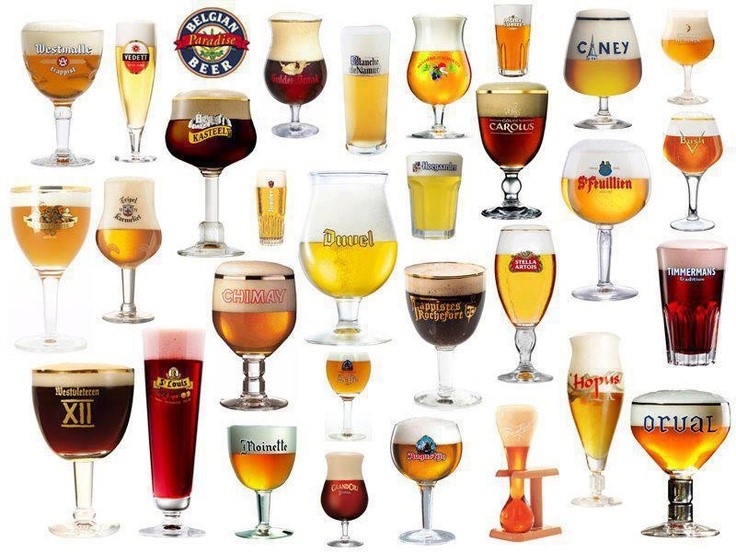

Beer is sold in places that I did not expect. For example, coffee shops had them, so did chocolate shops. However, my colleagues always insist on going to the neighborhood bars which are called “brown bars”. These places are always buzzing with people; typically opening late in the afternoon and staying open till the last guest leaves. These brown bars typically serve about 80-100 types of beers. Now, Belgians are very particular about their beers. For example, almost all beers have to be served in designated glasses; very few beers can share a glass. For example, Leffe Blond and Leffe Brown can go in the same glass. But for the most part, each beer has a distinct glass which apparently makes the beer taste right. As you can imagine, this means that each bar has upwards of 70 types of glasses, in all different shapes and sizes. I have no idea how they store those. See below a picture of some of those glasses.

Like I said earlier, beer is taken very seriously in Belgium. So, it is not enough to have the right glass; they also have to be cleaned properly. Just as the shape of the glass has a reason, the special washing mechanism also has one. It has to do with the need for the foam (aka the head) on their beer. It must be two inches thick, and forming a dome on the glass, otherwise it will be sent back! Now, if you wash your beer glasses in a machine, you can say good bye to this foam. To get the appropriate amount of foam, the beer glasses need to be extremely clean and cold. So, to accomplish this, there is a whole procedure around cleaning, complete with special equipment and all.

The size of the glass is such that when you pour a bottle, you get the entire bottle in there plus the requisite foam. If the person doing the pouring knows what they are doing, you end up with a perfect glass with just the right amount of foam. Ah the simple luxuries of life!

And now we finally get to the beer. If you think they are particular about the glasses and the cleaning procedure, how do you think they feel if the beer is not served at the right temperature? Here are just some of the nuances that I understood.

Some strong beers are served at 16°C Celsius (~ 61° F) for the older generation, which is quite close to the temperature in the cellar. However, the younger generation typically prefers those same beers cold at 4° C (~ 39° F).

A bar would have about 5-6 beers on draft; these are cooled instantaneously and therefore there is no need to keep the stock refrigerated. For other beers, the bar has to keep a certain amount of refrigeration capacity. As you can imagine, because of the large variety, the cold stock in the fridges at the bar is limited. So if all of a sudden a specific beer experiences heavy demand, the bars get in trouble with the temperature.

As you can imagine, the number of beers and glasses can be challenging to maintain. The need for cold storage for all the beers creates a different problem. Managing what goes into the refrigerator and what stays in the basement is an important task in running the bar. The person running the bar has an inventory management job when it comes to keeping the right beers in the refrigerators.

One issue though with beers on draft: they need to be popular enough to empty the keg within 2-3 days. For the light beers this is not really a problem as the consumption is typically quite high. By contrast, the consumption of heavier beers is lower. So the producers made smaller kegs to accommodate that. There are 2 types: 30 liters (~8 Gallons) and 50 liters (~13 Gallons). But this wasn’t small enough for a few specialty beers, so now there are also small tap installations for really small kegs of 5 liters (1.3 Gallons) capacity. One added benefit of this keg size is that they can be sold for home use. These guys must be very customer focused given they have so many innovations to support the customer needs.

On a supply chain level, there were some nuances to learn as well. Because the Trappist beers are so popular (surely because they are so good), in some cases, I learnt that the same beer was available under a non-Trappist brand (product substitution anyone?). I also learned that some Belgian beer is hard to find in Belgium, because the brewers can make more money by exporting it to the US. For some beers, the price could be as much as 8 dollars more in the US. Obviously, my Belgian colleagues are not happy about this.

And then I learned about the case of the company that is building an underground pipeline to transport the beer from the brewing to the bottling facility. This company, De Halve Maan, has been brewing in the heart of Bruges and they do not really want to move. Currently, the transporting is done via tank trucks and the company is investing in a 3 km (~1.8 miles) pipeline to transport the beer. They even started a crowdfunding campaign for the underground pipeline. After the campaign was announced, the brewery received a lot of emails from locals asking for their own beer faucet in their house. (To that, I say bravo!) While that is not feasible, the campaign has a few options which are in line with the request; you can read about them here. Impressive supply chain stuff if you ask me.

I was able to sample quite a few during my short stay and they were all very good. My personal favorite is the Rochefort; a beer that I first tried a few years ago with my colleague Jelle Clement at Ghent and make it a point to enjoy each trip. Philip also introduced me to the oak aged La Trappe, which, I was surprised to learn, is actually from the Netherlands (and also very good). Billy’s favorite during the trip was Tripel Karmeliet, a beer that always gets ranked very high in reviews.

While the beer is very good, I must not forget the conversations I had with my friends and colleagues while having those beers. Belgians are fun and friendly people, and even more so when having a beer. I cherish the experiences and the friendships.

I hope some of you will get to try some of these beers and maybe a couple of you will ponder the supply chain question in more detail. In the meanwhile, I wish you the best. Cheers!

Like this blog? Here is a follow up blog post with some more information.

Follow us on LinkedIn or Twitter and we will send you notifications on all future blogs.