In a recent study, Gartner estimates that 50% of Supply Chain Planning Solutions are not fully utilized1. How can organizations ensure that they have the user adoption needed to attain the full benefits from their existing or new supply chain solution?

Look at the present to improve the future

From creating an autonomous supply chain with artificial intelligence to evolving supply chains with IOT, the future of the supply chain looks promising. Most businesses today are, however, not poised to take advantage of more futuristic supply chain innovations because they lack the foundational capabilities needed for those visions to take form. In fact, most analytical tools that are emerging in the marketplace draw their intelligence from existing processes and data to provide businesses with the intelligence needed to make data-driven decisions. Even though it’s easy to look at the future capabilities that your supply chain may need it might be more prudent to look at what you can achieve today using existing technology solutions.

Get started the right way

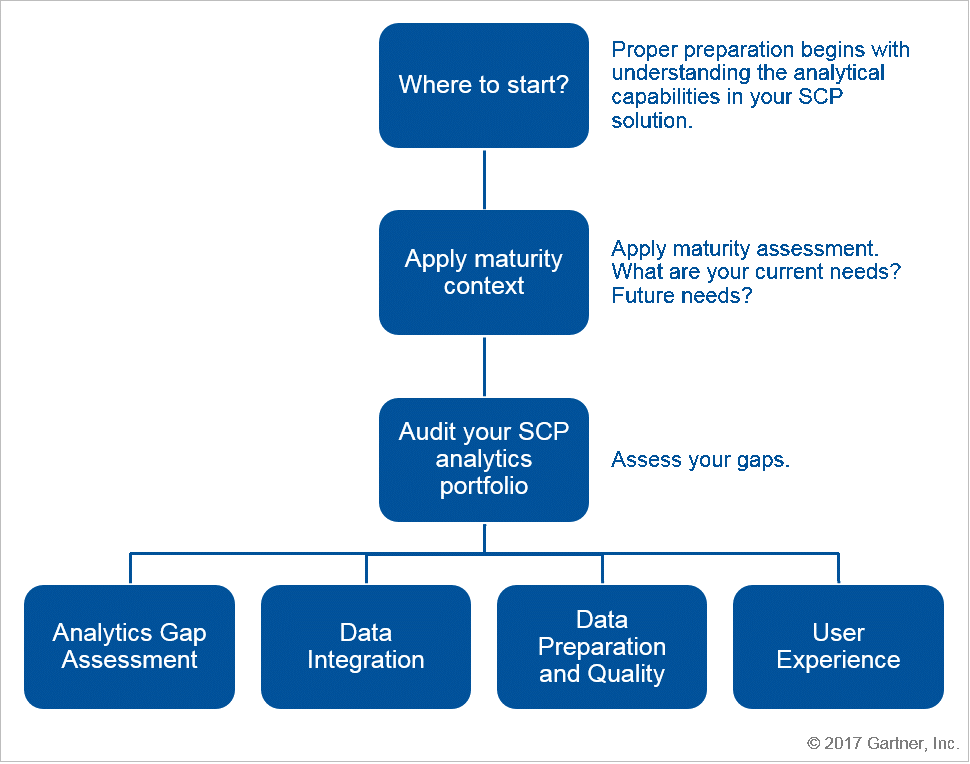

The good news is, full-scale supply chain planning solutions like Arkieva come standard with advanced decision-making tools including ‘what-if’ scenario capabilities, rule-based optimization, predictive analytics and visibility dashboards. The Gartner research paper was written by Gartner Analyst, Alex Pradhan on “When — and When Not — to Buy Additional Analytical Capabilities for Your Supply Chain Planning Process” outlines the following steps for auditing your SCP analytics portfolio:

- Gap assessment

- Data integration

- Data preparation and quality

- User experience

Source: Gartner, “When — and When Not — to Buy Additional Analytical Capabilities for Your Supply Chain Planning Process,” Alex Pradhan, (March 2017)

In addition, the research highlights the need to “maximize the value of existing software” by training to boost productivity, implementing projects that drive data quality and integration, and working with solution providers to help businesses leverage analytics and make better decisions.

[Read More: How Do You Model Inventory in Planning Systems?]The other side of the coin

There are many businesses still running core supply chain planning processes with “highly-complex” Excel spreadsheets, legacy applications or solutions that simply do not provide the business flexibility needed for continuous improvement and analytical decision making. For such businesses, employing a more digitalized supply chain process might be the way to get started.

Enjoyed this post? Subscribe or follow Arkieva on Linkedin, Twitter, and Facebook for blog updates.

12017 Gartner Supply Chain Technology User Wants and Needs Study, Dwight Klappich