Despite all the bad news regarding container ships stacked up at ports, pandemic related labor challenges, and chip shortages, there have been a few bright spots regarding the supply chain. In this blog, we’ll examine some of these. Not all will apply to you. For example, not every company has the resources to own their freight company and leverage it as Alibaba did to provide “supply chain as a service” in China. But the general ideas around vision, technology, and sustainability apply to all of us.

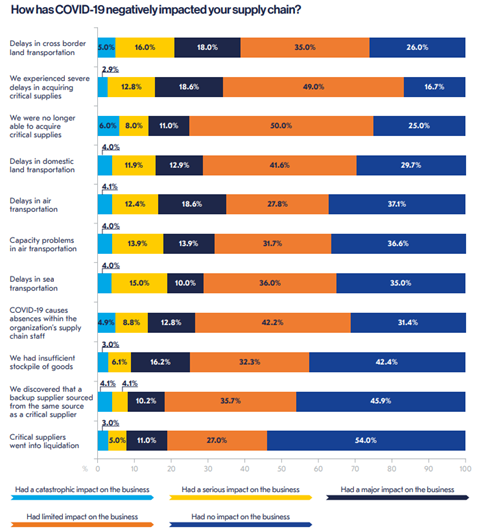

Let’s begin with this chart from the 2021 Business Continuity Institute (BCI) annual report on supply chain resilience and the literal guest who would not leave, COVID-19.

It’s interesting that despite the focus on issues with the ports, air transportation has the greatest percent of catastrophic to major impact on business. I hope this is not due to air accidents. This is one of the areas where Amazon identified risks years ago and built a fleet of planes that may eventually rival FedEx. Their decision to own their supply chain has paid dividends in todays constrained supply chain. Amazon is not all the way there yet, but they have set a path with a ruthless vision to cut out 3rd party shipping companies. Owning your own destiny is something all businesses can strive for, regardless of size or industry.

The ability to overcome supply issues also seems to favor newer companies. GM had to work around the chip shortage by not offering some standard or expected options and reduced production by 200,000 in the second half of 2021. However, Tesla was able to manufacture close to 1 million new cars globally last year without significant delay. According to Supply Chain Digital, this was because Tesla built a new car platform (and vision) from scratch whereas legacy companies had to build around existing platforms and processes. This increased the complexity of the supply chain needed to support GM’s manufacturing. In an industry where there is strong brand loyalty, the lost sales due to production cuts may have a long-lasting impact on GM’s future market share.

Still, many legacy companies did well in this era of almost continual disruption. Gartner’s recap of the 25 best supply chains is chock-full of very well-established companies such as Colgate Palmolive, Intel, Walmart and Pepsi.

- At the start of COVID, Pepsi did a quick pivot to direct-to-consumer fulfillment through two selling sites: Pantryshop.com and Snacks.com. This gave consumers the ability to order what they wanted, when they wanted it. From a supply chain perspective, it became much easier to fill orders from a centralized site as opposed to stores that Pepsi was not staffed to distribute to.

- Walmart invested $11 billion in back-end infrastructure to launch Walmart+, their answer to Amazon prime. Maybe this was a knee-jerk reaction to Amazon, but with this investment, Walmart is keeping pace with the trend-setter in retail.

- Intel is investing $20 billion on two new plants in Arizona to boost capacity and reduce dependence on China. They are also working towards generating 81% of their energy requirements through renewable resources. This will indirectly save 7.1 billion gallons of water.

- Colgate is trying to keep production lines running more efficiently and longer by using AI to predict maintenance needs. The ability to predict mechanical breakdowns will reduce production delays and tighten their service parts ordering/inventory.

Inevitably, this type of response to our current challenges will trickle down to all of us. It’s a copycat world, but you do not have to be at the bleeding edge to win-out. All you need is the vision to learn from the market and act. And we may not all have the resources to build plants and aircraft, but we can focus on the little things that make a big difference. Sustainability and reduction of resources needed to make things is something we all can do. You can learn more about sustainability and the “circular supply chain” in a recent blog by our Senior Consultant, Dr. Vicki Folmar.

What supply chains do you admire? Is your way to gain efficiency focused on getting the right people, the right technology, or becoming more sustainable (or maybe a little of all three)? Share your thoughts in the comments section. We look forward to hearing from you.