Happy New Year! Over the past year, the Arkieva Supply Chain Link Blog provided thought leadership and informative posts on supply chain strategy tips, trends, and news. Just in case you missed some of our supply chain strategy posts, we have compiled a list of our popular supply chain posts from 2020 below (ranked based on shares and views). If you would like to avoid missing a post in the future, please subscribe here.

Here is a list of Our Top 20 Supply Chain Strategy Blog Posts from 2020

An ongoing challenge for any firm is estimating demand for new products. This is especially true when the product has new technology or is replacing an existing product and the additional function in the new product is limited. Often a mathematical construct called an S curve is helpful. This blog provides an overview of S curves and why they can be helpful. View the full post.

Inventory Forecasting is the process in which the historical sales data, historical purchasing data, current demand planning, planned production, and distribution resource plan data are used for predicting inventory levels in a future time period. View the full post.

With the current COVID-19 challenges, “models” have taken center stage. Models are being used for estimating the number of COVID-19 hospitalizations and deaths with and without mitigation, how much of each resource will be needed (ventilators, beds, PPE, testing, etc.), and now how to optimally handle economic reopening with minimizing COVID-19 health impacts. Based on over 500 years of SCM modeling experience at Arkieva there are some critical lessons that are crucial to maximizing success against COVID-19. View the full post.

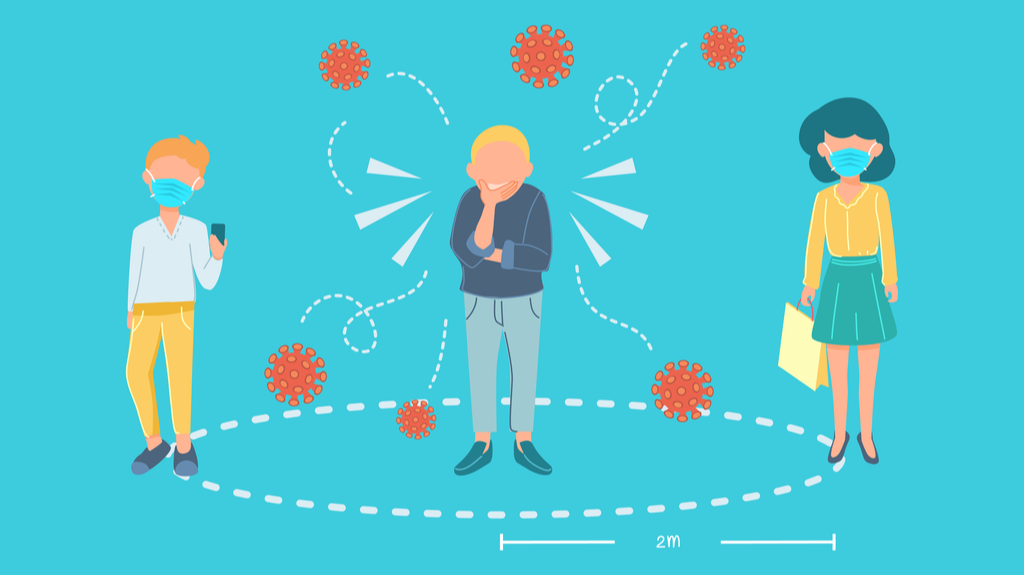

The tragic outbreak of the Coronavirus has again demonstrated the need for ever vigilant health care services and fast response. It has demonstrated that supply chain interruptions from a manufacturing excursion to a port strike to an infectious disease outbreak require two actions from any firm: preparation and response. View the full post.

A common question is how to best manage safety stock for critical raw materials that are critical to the production of the exit product for a firm’s supply chain. Yes, traditional methods can be adapted for critical raw materials. However, it is not uncommon to find methods quasi-specific to raw materials used in industry with reasonable effectiveness, although the fundamentals of inventory management remain the same. View the full post.

We see graphs of COVID-19 events on a regular basis. One of the most common is a bar chart for daily new events (COVID-19 cases, hospitalizations, deaths). Recently in presentations, smoothing methods used to overcome limitations are presenting the raw daily data. This blog will take some of the mystery out of smoothing methods. View the full post.

We see graphs of COVID-19 events on a regular basis these days. Two common ones are bar charts for daily new events (COVID-19 cases, hospitalizations, deaths) and the “sweeping curve” to capture a cumulative number of events. Additionally, log transformations are mentioned. The purpose of this blog is to shed a bit of light on these curves and the role of the log transformation. View the full post.

An often-heard theme in supply chain management (SCM) and COVID-19 is “data-driven” – being data-driven is the path to success. For COVID-19 “science-driven” is often said in the same sentence. For SCM, demand or customer-driven replaces “science”. This blog will point out a few examples in the COVID-19 challenge demonstrating COVID-19 is an OM challenge. View the full post.

A colleague and I were talking recently, and the conversation turned to what is the relationship between Mean Absolute Deviation (MAD) and the Standard Deviation (STDEV). In this post, I will explain to you the math behind that approximation, which by the way, only applies to normal distributions. View the full post.

This material provides some basic guidelines to determine if the data is quantitative or qualitative with a focus on areas in the shadow where it is initially not clear. With analytics the rage in executive discussions, it addresses a question that is often a stumbling block to a successful outcome. View the full post.

For most involved in Supply Chain Management, optimization is viewed as one of the three primary methods to create a supply or central plan that matches or balances assets with demand. Historically effective use of space involved minimizing unused space or maximizing revenue from a fixed amount of space. COVID-19 has upset the social order. View the full post.

Arguably the two most important core components of managing the supply chain or demand-supply network are demand management (DM) and Central Planning (CP). CP is sometimes referred to as master planning or supply planning. DM is focused on developing and quantifying a robust understanding of exit demand for an organization. CP is focused on understanding the impact of the estimated demand on the network to acquire, produce, and deliver exit products to customers. This blog will provide some basics about Central Planning. View the full post.

Inventory comes in many forms and flavors; it is the critical element of supply chains that enable a firm to respond quickly and take advantage of scale. However, managing inventory is one of the most difficult aspects of supply chain management since there are competing forces – some pulling for more inventory and others for less. View the full post.

Picking up from where I left off in my previous blog, I will look at a few more scenarios in both short and long terms in this blog. Even though Brexit is the theme for these scenarios, the underlying principles apply to any situation with uncertainty in supply planning. View the full post.

In the simple version of supply chain management (SCM) the goal for demand forecasting in the tactical decision tier is prediction accuracy. In the wiser version, the purpose is expanded to include an understanding of your demand (demand profiling), bound the level of accuracy possible by using demand history and using this information to support demand and inventory analysis by putting in place programs to enable the firm to adapt to changing conditions. Getting to wiser forecasting requires the use of machine learning (ML) and automated intelligence (AI) combined with deep statistical knowledge embedded in software with expert system (ES) methods and the use of advanced optimization. View the full post.

Probabilities are persuasive in supply chains and analytic methods – especially in machine learning where conditional probability is a dominant underlying structure that makes or breaks the success of an application. However, their use is often hidden to supply chain professionals, or at best opaque, written in a formula such as P(s’,r|s,a) (from reinforcement learning). In fact, conditional probability is easy to understand, it is the probability of an event occurring if certain conditions or states are true. The purpose of this blog is to take the mystery out of the term ‘conditional probability’. View the full post.

This blog provides some basic information on the curve, relates statistical concepts to policy and actions, and examines policy options for a safe restart relating them to the APEX curve. There are three essential groups of action to begin a safe restart: testing, detailed understanding of the impact of mitigation actions, and the ability to do detailed tracking. View the full post.

The spread of the COVID19 virus is a major concern for everyone. Typically, two critical questions are being asked: why it seemed to grow so quickly over the last few weeks and what is the impact of social distancing. This blog provides a kitchen table explanation of “rapid growth” and how social distancing might dampen growth. View the full post.

Digital Transformation is a popular term being used in today’s supply chain world. This can mean different things for your organization based on your company’s maturity. In this blog, you will learn the five key points to consider in a supply chain transformation journey. View the full post.

The current COVID-19 situation highlights the supply chain management challenges in any turbulent time. In this blog, we identify five key points: preparedness, larger good, anticipate, and not react to events, responsiveness, and an intelligent stochastic estimate of demand. View the full post.