One of the impacts of the recent rash of “upending events” such as COVID, closure of Suez Canal, bridges falling, train derailments, shortage of products (computer chips, baby formulae, eggs, etc.), numerous severe weather activities, surges in demand for electricity, viral social media events that sink or spike demand, and “regular variability” is a recognition by many organizations that it cannot thrive simply with improvements in demand estimation and management of inventory — the critical requirement is responsiveness. This drives the need for supply or central planning and scheduling. Although historically scheduling has not been considered part of supply chain management, the best firms recognize the need for not just scheduling, but the dynamic interplay between scheduling and planning. This blog provides one perspective on the differences between planning and scheduling.

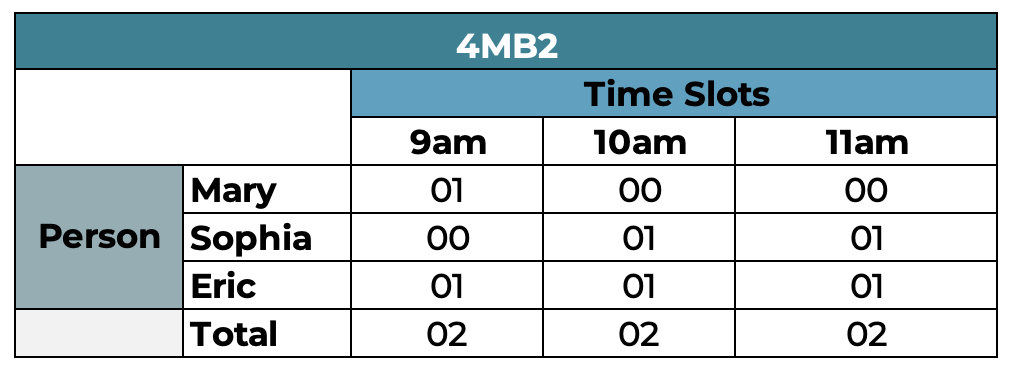

As an example, assume we have two conference rooms 4MB1 and 4MB2 and schedule requests are handled as 1-hour slots for these two conference rooms. The collective resource for these two conference rooms is referred to as 4MB. Table 1a illustrates the model structure necessary for scheduling where the rooms are kept separate for hours 9am, 10am, and 11am. Table 1b has the model structure appropriate for planning where we treat the rooms as one resource.

There are three requests for rooms:

- Mary for one hour starting at 9am

- Sophia for 2 hours starting at 10am

- Eric for 3 hours starting at 9am

Table 2 summarizes this demand:

The plan will compare the last row in Table 2 (total) with the information in Table 1b, total room capacity. Since demand is equal to capacity available and all demand is met, we have a plan that makes everyone happy (notice we avoided using the term optimal).

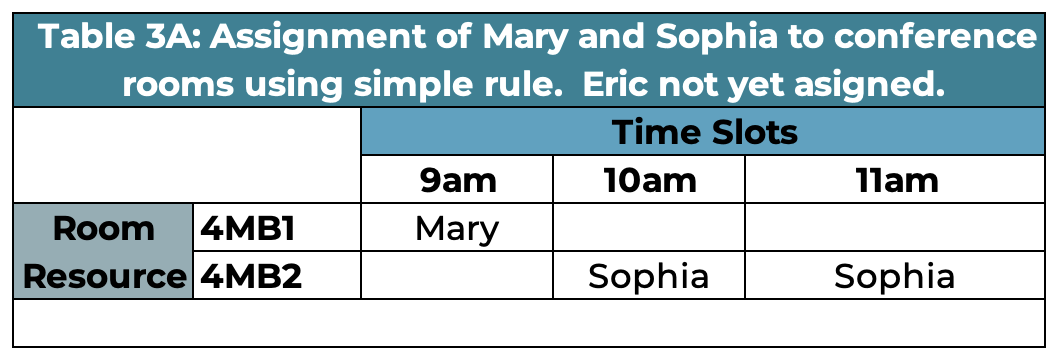

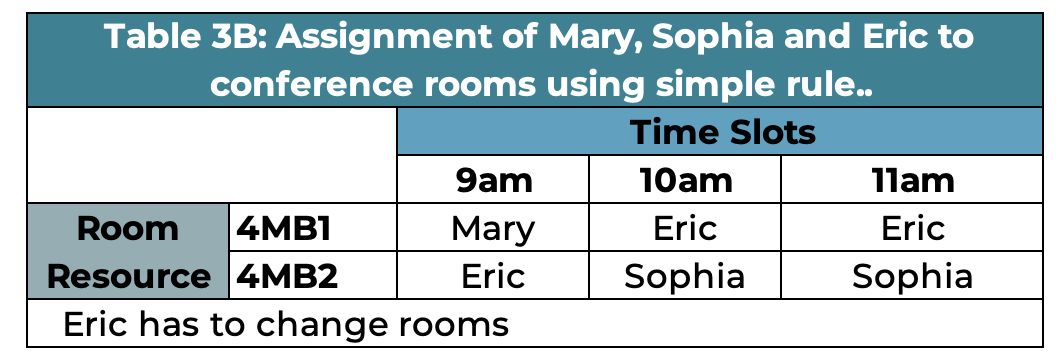

Can this plan become an effective schedule? This requires assigning requests to specific rooms. A simple rule (fancy math term is greedy) would be to go sequentially through each request and make an assignment. In this case:

- Mary is assigned to 4MB1 for the 9am slot

- Sophia is assigned to 4MB2 for the 10am and 11am slot.

What about Eric? He gets the non-assigned rooms. He has 4MB2 at 9am and then switches to 4MB1 for the 10am and 11am time slots. This is shown in Table 3b. Although feasible, it is not preferable since Eric has to switch rooms.

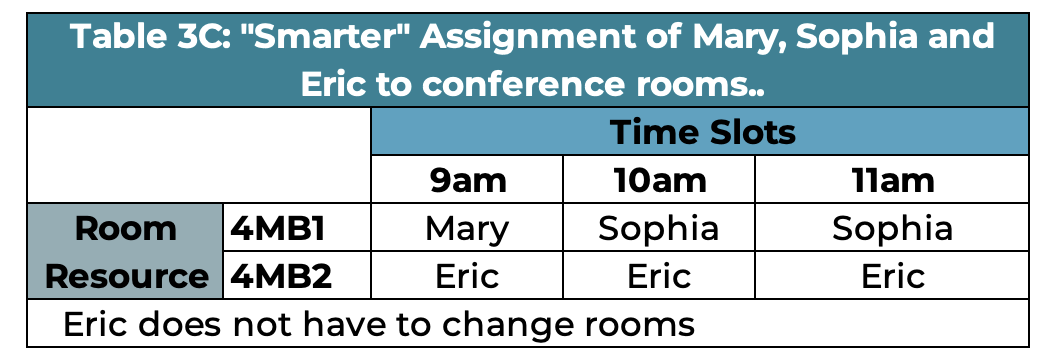

Visually it is easy to improve the schedule by moving Sophia to room 4MB1. The improved solution is shown on Table 3c. Are there alternatives to the greedy algorithm, – yes, but outside the scope of this blog.

From this example, the reader should have a basic understanding of the difference between a plan and a schedule.

About the Author: Venkat Nagasubramanian

Venkat Nagasubramanian, currently serving as an Optimization Expert in Pre-Sales, brings a wealth of experience from his consulting background where he led the implementation of decision support systems and optimization models. With a master’s degree in industrial engineering, Venkat excels in the realm of supply chain optimization, demonstrating both analytical acumen and strategic insight. Outside of his professional commitments, he is an enthusiastic biker and soccer lover, reflecting a comprehensive dedication to excellence in various aspects of his life.