The supply chain planning team is an integral part of a functional Supply Chain Execution (SCE). How an organization is structured can affect the overall supply chain process. In this week’s, Supply Chain Talk, Arkieva CEO Harpal Singh discusses how organizational supply chain planning structures can be improved.

During an orchestra performance, when things are going well, no one notices the mannerisms of the conductor; everyone seems to be captivated by the music. However, when there is a discordant note, the audience notice the conductor and could blame him or her for the error.

Supply Chain Planning is similar.

No one notices the supply chain problems that are routinely avoided. On the other hand, when there are problems, the supply chain team is the focus of everyone’s wrath.

The Supply Chain Planning Department has a unique position compared to the other staff departments because they deal with the future, and the future is always uncertain. The fact that all plans are wrong with varying degrees does not help their credibility. This makes their role of trying to balance the two powerful operational areas (sales and operations) by getting them to work harmoniously towards the same goal especially difficult. It puts them in the unenviable position of trying to control two powerful forces (with sometimes conflicting goals) at the same time.

How do most supply chain structures in organizations look like today?

Usually, supply chains in an organization exhibit stages of evolution depending on the life cycle of the business, the maturity of the organization, and the nature of the business. For example, it is rare for a very profitable (high margin) business to have a mature supply chain because they are more profitable by continuously innovating and not by streamlining and optimizing processes. Pharmaceutical companies and “fabless” semiconductor companies are good examples. Their focus is usually on the design and creation of new products and not on necessarily on making and selling products efficiently.

Most supply chain organizational structures fall into one of the following categories.

- No true Supply Chain planning department: This is usually restricted to very small businesses that can do its planning activities using a single individual. Nonetheless, with markets becoming demand driven, smaller manufacturing businesses may find it difficult using this type of model if they want to meet market demands.

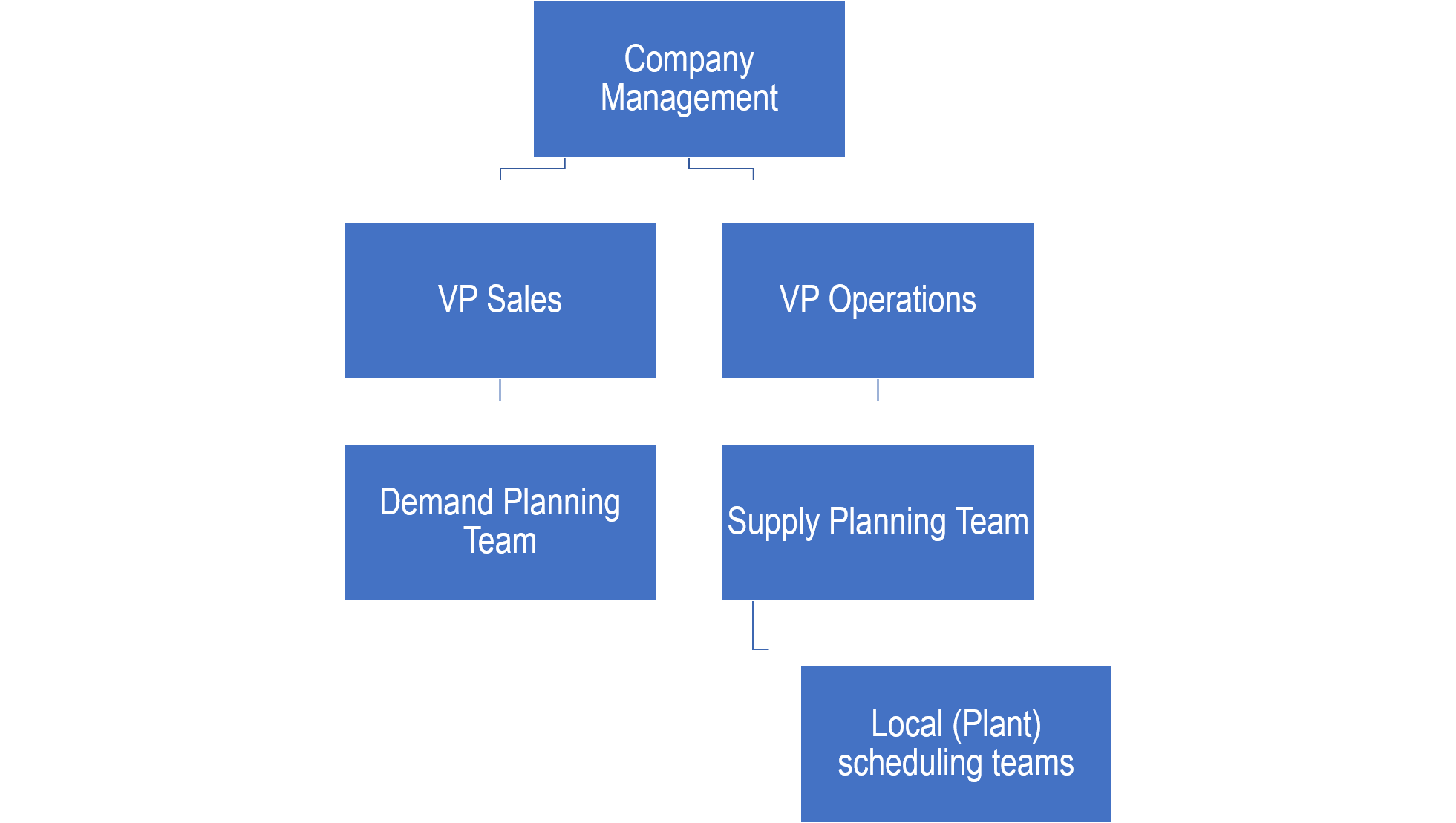

- An organization where ‘Demand planning’ is the responsibility of sales and ‘supply planning’ is the responsibility of operations: This is by far the most common supply chain organizational setup but is minimally effective because it is like the fox guarding the hen house. Demand planners reporting to sales will inevitably bias the forecast to achieve improved sales metrics. Supply Planners that report through operations will have the best interests of the plants at heart and will plan uninterrupted runs of materials resulting in more inventory than needed. This structure guarantees constant friction between the demand planning and supply planning functions. Figure 1 below illustrates the organizational hierarchy for this type of supply chain organizational structure.

Figure 1

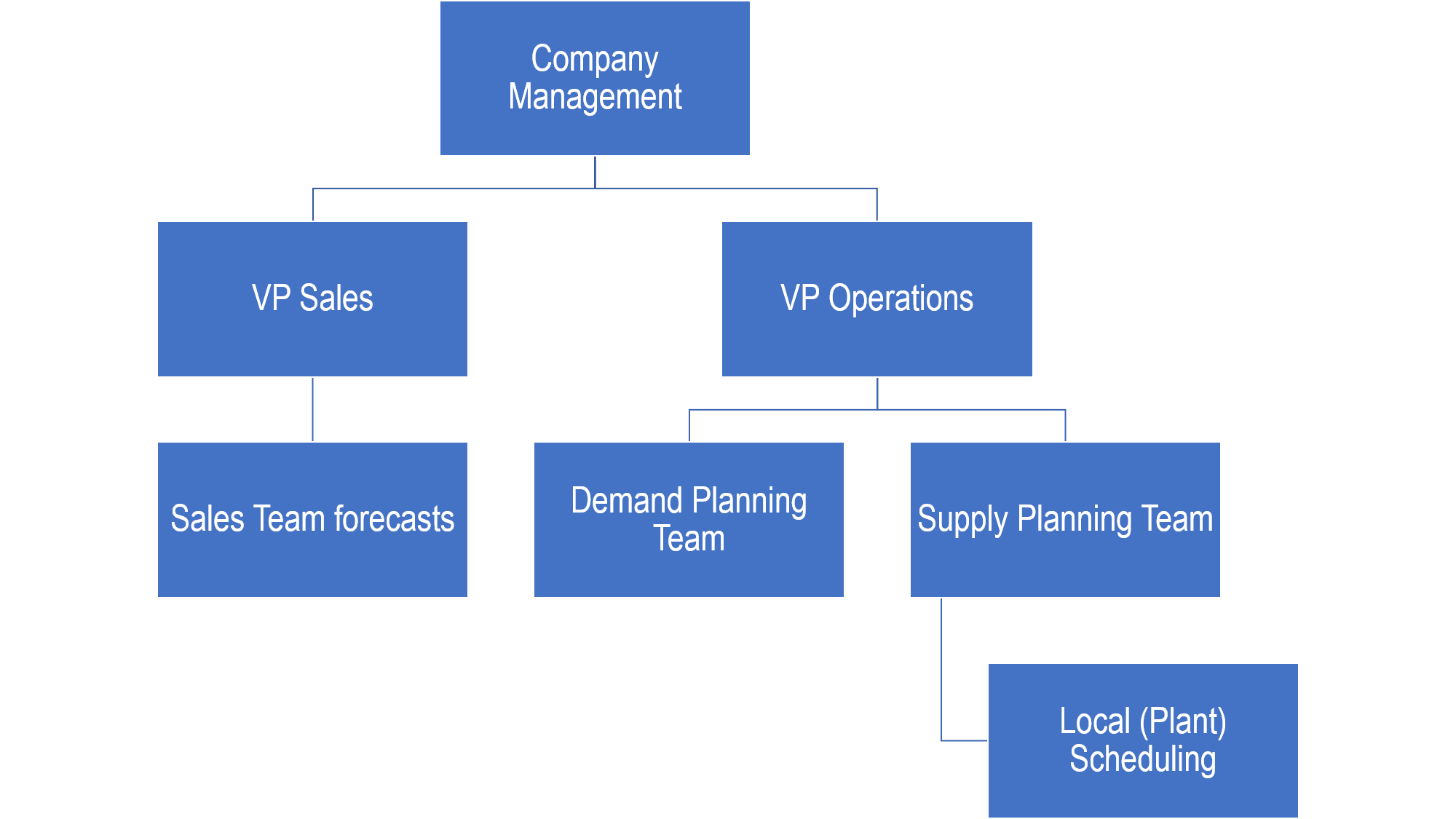

- Both demand and supply planning report through the operations: This setup is slightly better than the one above in that, it at least keeps the entire Supply chain together. However, it still has drawbacks. This type of organizational structure tends to become sympathetic to the operations metrics and usually shortchanges the commercial or sales organization. The following diagram shows this setup.

Figure 2

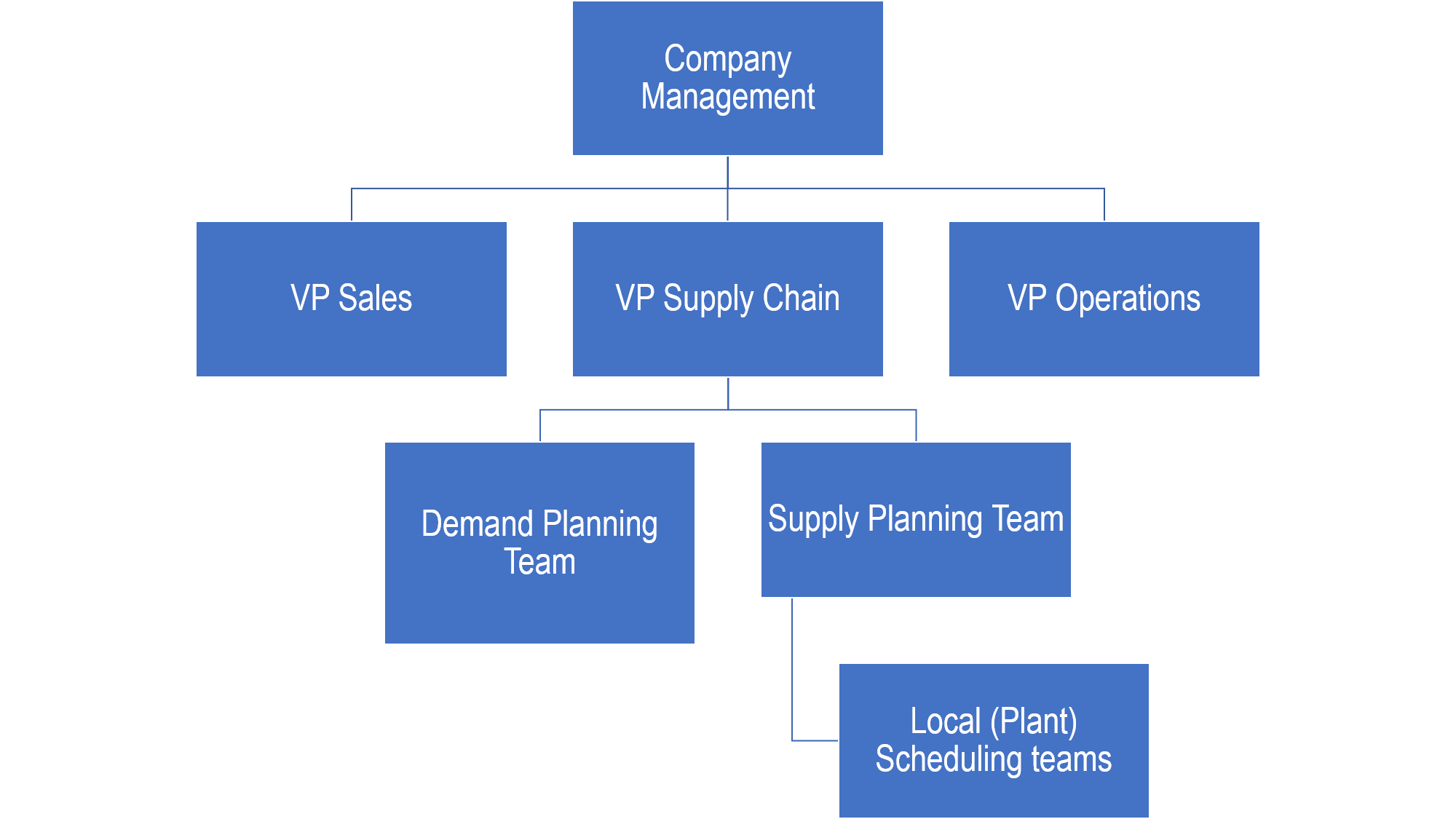

- An independent Supply Chain Organizational Structure: With this type of organizational structure there is usually a VP of Supply Chain (or equivalent), and he or she gets an equal (or almost equal) vote at the table. Both the demand planning and supply planning team report through this VP. This always results in better decision making because of the lack of conflicting metrics and interests. An organization with this type of structure usually treats supply chain as a competitive advantage and proactively uses planning to make money for the business. However, this kind of organization has its challenges in that it must enforce decisions through influence, persuasion, and consensus building.

Figure 3

Based on this, the logical organizational structure would appear to be the one with a “VP of Supply Chain.” The exception might be when manufacturing complexity is a factor. In that case, the demand that can be serviced depends on how the assets are tasked and the demand planner needs to understand the intricacies of manufacturing and the current operational constraints. It is helpful if the demand planner reports through manufacturing or operations.

The reality is that irrespective of where the supply chain planner is located within the organization, he or she must develop matrix relationships with sister organizations.

[Related: Supply Chain Talk: Do Numbers Tell the Full Story? ]A more effective structure is one where the day-to-day scheduling group is within the supply chain planning section of the organization. This goes a long way to ensure that plans are translated into scheduling tasks that support a company’s overall goals.

Effective supply chain planning processes require collaboration and information sharing between planners. This cannot be solved using a particular organizational structure because all organizational structures are inherently compromises.

What does it take to make supply chain planning teams more effective?

For Supply Chain Planning teams to be effective, they require two main elements:

- Success should not ONLY be measured based on functional efficiency

Their success needs to be judged using the overall objectives of a company, and not by metrics that only measure functional efficiency. Supply Chain Planning teams are effective when they are avoiding problems and crises. These are reflected ultimately in growth, market share, and profitability. Traditional metrics like days of inventory, average cost, and others are not sufficient.

- Supply Chain Planning Teams Should Have Authority

Although the main task of a planning team is to coordinate the activities of other functional areas, it must have the authority to enforce a compromise. The tactical plan (commonly known as the Sales and Operations Plan) is the result of a process that considers the demand and the resources needed to support that demand. A company can only be successful if it routinely establishes a common companywide plan and then directs its activities to achieve the plan. The role of the Planning Department is to measure adherence to the plan and establish the parameters that allow deviation from the plan. To accomplish this, the planning department must have the needed authority.

[Read: Supply Chain Talk: Are Best Practices Always Best? ]Conclusion

The goal of a supply chain planning team is to “optimize the whole, not the parts.” Their objective is to make the best decisions for the corporate bottom line that aligns with the strategic business direction. To create the optimal supply chain planning team and process, it is imperative that the supply chain planning team stays focused and is not distracted from their objectives by having competing goals.

Have a supply chain topic that you would like us to discuss? Join the Arkieva Supply Chain Talk with Arkieva CEO Harpal Singh. Add a comment below or send a tweet to @Arkieva with #ArkievaSCT, or email editor@arkieva.com.

Enjoyed this post? Subscribe or follow Arkieva on Linkedin, Twitter, and Facebook for blog updates.