Recently, I was visiting with a prospect in Pennsylvania and they lamented on the effect of the ongoing port shutdowns on the west coast. He went on to say how they have heard of a threat for a shutdown for many years and everyone had become accustomed to it. When the noises for a shutdown started again this winter, no one paid much attention to it. Alas, the strike actually happened and now the business is hurting.

I am sure this business is not alone in this predicament. Nor is my prospect the only one who ignored the warning. However, as a supply chain planning professional, the thought did cross my mind. What, if anything, could this prospect have done in advance just based on the possibility that something like this could happen? He did not even have to think of the strike as the cause; any number of natural occurrences could have caused such a port closure.

And then there was the case of a meeting I attended with various business leaders and one of the questions was about the falling oil prices and the impact on their businesses. While no one minded the decrease in the price, all were worried about the inflection point that was inevitable if the trend continued making it viable for competition to enter their markets. Again, I found myself wondering whether they could get a reliable answer to these questions.

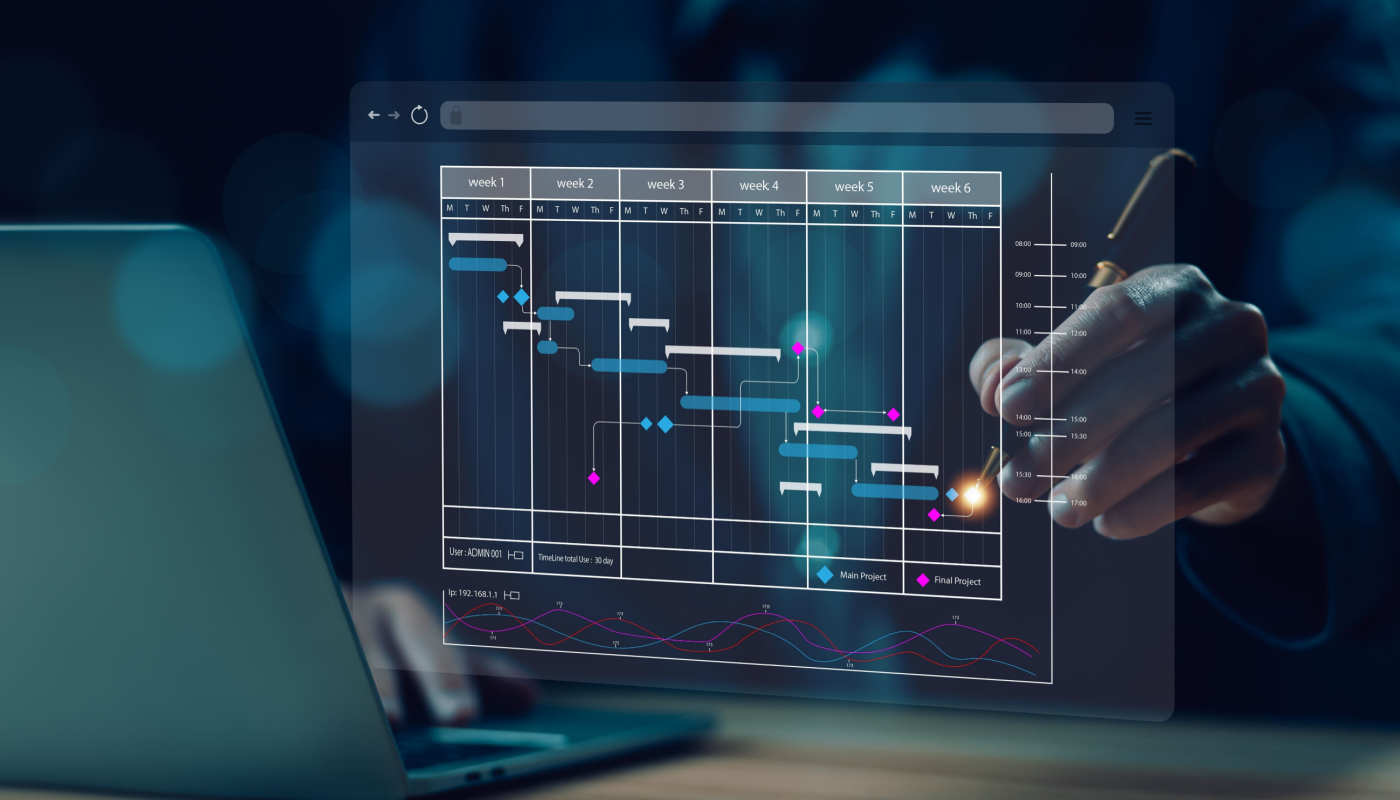

In my mind, this comes down to whether or not a company has an adequate investment in tools that allow them to do what-if scenario planning. At the end of the day, a port shutdown can be described in a supply chain model as a simple loss of capacity at the port (instead of 24 or 18 hours available for work per day, now we have 0 hours available). Or in the case of the oil prices, if oil is one of the key raw materials, then multiple versions of future price tables can be created, showing various expected scenarios of price decrease. Once this is done, and assuming that the model is appropriately structured with all the points in the network, the planner can solve with the new data and have answers ready to go. What is really nice is that the planner need not worry about the cause, only about the data condition that appropriately describes the prevailing situation on the ground.

Having such a model allows a user to be prepared with these types of what-if scenario results. Then, if such a condition becomes highly likely, or actually happens, the business can pull out this alternate plan and execute to it.

One of my clients to run such a model and multiple what-if scenarios in Arkieva to evaluate the what-ifs for his raw material pricing and even used it do some hedging! Now that is a clever way to make money using better planning.

A key requirement in being able to do this type of what-if analysis is the availability of an appropriately robust model with editable data fields so that the what-if conditions can be approximated into the model. If such a system does not exist, then what-ifs will be very tedious if not impossible leading to an increased level of firefighting.

Like this blog? Follow us on LinkedIn or Twitter and we will send you notifications on all future blogs.