I was asked recently about what it takes to transform the supply chain planning process of a company. Having gone through this process a few times in my past, I thought it best to share my experiences and suggestions in the form of a discussion with Tapan Mallik during a webinar. This blog is a precursor to that webinar.

When it comes to the transformation of supply chain planning, typically one needs to look at people, processes, and technology. The best results are achieved when the changes in these three areas are brought through close to the same time. Otherwise, any improvement in one area could be derailed by the lack of improvement in other areas. For example, if the people are trained on new processes, but the technical support is not provided to enable those new processes, things will quickly revert to the same old, same old. Conversely, if a technology acquisition and deployment is made, but processes are left unchanged, likely you will have the same bad results, albeit faster. And it is crazy to think about any process change without bringing the people along; it simply will not happen except in the case of some automation tasks.

When it comes to the people, the business needs to think of the level of expertise that exists within the organization and make decisions accordingly. There might be a need to hire new people to fill in some gaps. Almost always, there is a need to provide training and education for new processes and Technology. There should also be a program of ongoing training until things become ingrained.

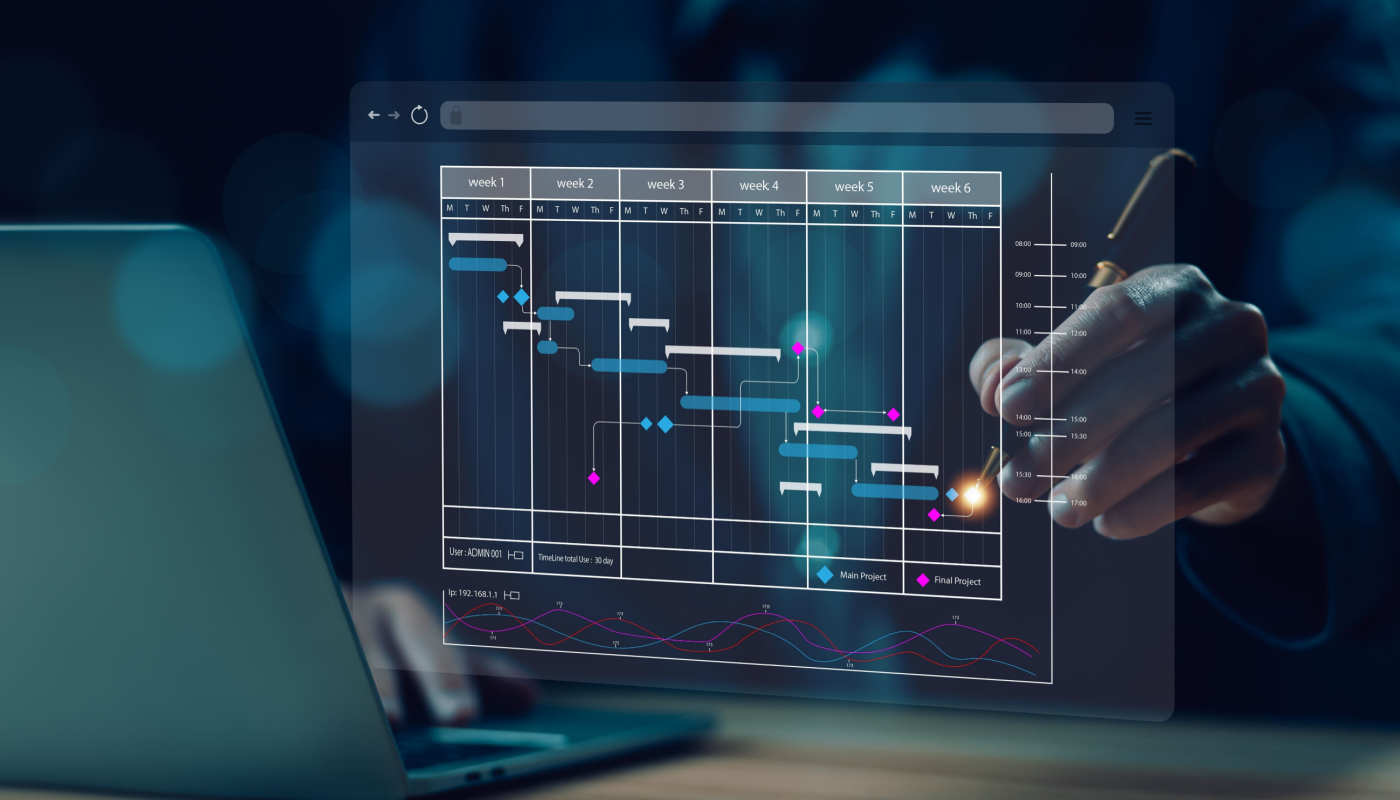

When one thinks of planning processes, one needs to clearly demarcate the different areas, for example, demand versus supply planning. One also needs to be aware of the differentiation between planning processes and transactional processes. Running your planning like transactions is a recipe for disaster. At the same time, a plan that cannot be executed via transactions is worth less than the paper it is printed on.

One also needs to consider the capabilities of the existing ERP system. Despite long-standing claims, most ERP systems remain woefully inadequate when it comes to planning. At the same time, most planning systems are found wanting when it comes to executing transactions. One needs to choose wisely which system controls which part of the process. A best practice that I recommend is to use the ERP system for transactions and use a supply chain planning (SCP) system for planning.

One other thing that needs to be considered is the capabilities required in a yet to be acquired supply chain planning system. Supply Chain Planning deals with a lot of different areas: Demand Planning, Inventory Planning, Aggregate Supply Planning, Master Production Scheduling, Finite Scheduling, etc. Each area comes with unique requirements for the software. Businesses need to evaluate carefully while taking into account the features, but also the fit with the people and the processes. Very often, I see spreadsheets where the list of functions/features needed runs into 100s per area, which is about 80 too many. Keeping the appropriate focus on the business value and not on every single feature ever imagined is very important.

Last but not the least, a business needs to consider what needs to be done by external parties and what should be tackled internally. If the company has a center of excellence, a lot of process and people related work can be done internally. Technology, though, is best bought from an external party. Depending on the situation at hand, a different mix of internal and external sources will make sense. A strong partnership between internal and external teams increases the odds of success. Even where companies have a Center of Excellence, it typically needs to be complemented by a group of external consultants. For sustainability of transformation, it needs to be owned and led (maybe co-led) by both internal team and external partner. Success also requires a close working relationship/synergy between the “process folks” and the “technology folks”. These are never typical IT projects.

On January 28, 2021, Tapan, and I will present our experiences and ideas in a webinar. In this webinar, we will talk about how to carry out such a project based on the experience of Arkieva as well as discuss some best practices. The details are below. Please join us.