Decreased service levels? Missed orders? Unhappy customers? These and other production scheduling challenges can be solved by putting the right software platform in place.

Manufacturers are under immense pressure to produce goods, fulfill orders and deliver on-time and in-full (OTIF) to their customers, whose needs are constantly fluctuating. Thriving in this high-octane landscape requires high levels of efficiency, accuracy and productivity. Manufacturers are also expected to minimize waste, stay profitable and exceed expectations amid ongoing supply disruptions and a constrained labor market.

Production schedules done on spreadsheets and shared via email may have cut it 10 years ago, but these antiquated approaches are falling short in today’s manufacturing environment. Basic software solutions also don’t make the cut, and very often just leave manufacturers grappling with decreased service levels, missed orders and unhappy customers. Other signs that it’s time to implement an advanced production scheduling platform include frequent stockouts and overstocks; excessive changeovers that impede capacity; and greater production line inefficiencies.

Four Signs that it’s Time for a Change

Here are four more production scheduling pitfalls that manufacturers can avoid by using the right advanced planning software approach:

- Using a “plug and play” approach with production scheduling. No two production plans are the same, and no two companies are going to use the same approach when managing their individual planning processes. For example, both pharmaceutical and chemical companies need to be able to trace their end-to-end supply chains by product batch, but not all companies need this capability. This is one of many reasons why out-of-the-box, generic software applications fall short. These systems are also too rigid and don’t support the many different unique configurations and constraints that each company brings to the table. For best results, the software must be customizable enough that it can be applied to that particular business.

- Lack of sequencing insights for the manufacturing line. Companies know they have to make products A, B and C within a given week, but they don’t always have the insights to prioritize these batches optimally. For example, a specific customer may be in urgent need of product B, which would put that job first on the prioritization list. But if schedulers don’t know this, then product B may be put on the backburner until product A is completed. With an integrated scheduling platform, the sequencing gets done right the first time, and every time. This is especially critical in operations where it takes time to change over from one product to the next, and where it may make most sense to do product A and then product C in order to minimize downtime and avoid potential disruptions. When integrated with schedules, these details ultimately help maximize production efficiency and improve resource utilization.

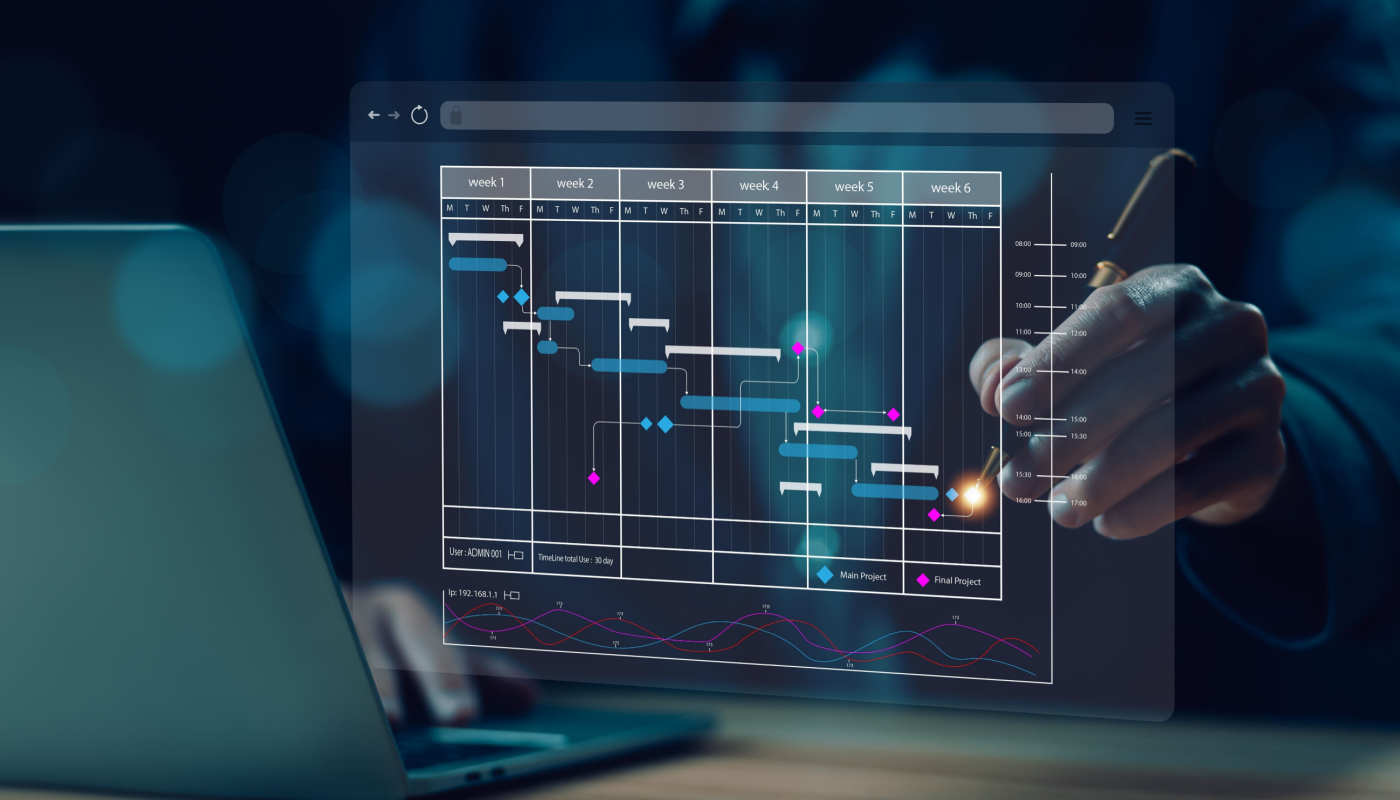

- No integration with sales and operations planning (S&OP) applications. The difficult job of a scheduler is complicated by the variety of sources from which they must gather information. In fact, a scheduler can spend a large share of their time simply rounding up the right information needed for decision-making. Communicating with colleagues to account for projected demand and receipts of raw materials for the next several weeks, as well as with the shop floor to understand production status and anticipated shutdown schedules are time-consuming steps. Automating by integrating data from S&OP systems into scheduling software can dramatically simplify this intake process and provide the scheduler with a single, efficient view of all the necessary information. But because scheduling tools are such bespoke solutions, they require time and effort to deploy, and not all supply chain software companies find them to be an attractive business. For this reason, many providers do not have their own scheduling tool within their product suite, so to fill this gap, they work with another company to tack on a third-party scheduling application that operates as a standalone solution. Information has to be transferred back and forth from the application to other systems, a cumbersome exchange that introduces lags and errors into the process. An integrated scheduling application solves this problem and provides all of the demand forecasting, inventory optimization and scheduling capabilities needed to create a closed loop for planners. With Arkieva’s end-to-end integrated solutions, all of the relevant data is stored in one unified data model and easily flows across scheduling, demand forecasting, planning and other systems that rely on that information.

- An incomplete framework for creating and evaluating scheduling outputs. A successful software implementation should account for all of the available institutional business knowledge, and include the training and support needed to optimize the planning solution that you’re putting in place. This is why Arkieva works closely with customers’ experienced planners to factor in all business characteristics and constraints when setting up the model and customizations, to implement a solution that truly meets business needs. Scheduling professionals are constantly balancing conflicting objectives from different functions within their organization – marketing may want the scheduler to react to evolving needs at the drop of a hat, meanwhile the manufacturing team on the ground is frustrated with the resulting schedule changes. To help the scheduler meet competing demands, a quantitative framework must be created to measure just how “good” a schedule is in practice, and to help schedulers visualize how changes to the schedule could impact key metrics. Not having these key metrics to work with is a lot like trying to navigate the ocean without a compass, but that’s exactly what many manufacturers do on a daily basis. Without key metrics to guide production scheduling and adjustments, planners have to rely on a lot of guesswork and estimating to get the job done. Knowing how many orders you shipped out OTIF, how many were sent out late and how many partial orders left the facility can help planners better hone their forward-looking schedules and understand the downstream consequences of making last-minute tweaks. This is why Arkieva provides detailed dashboards and an easy way to visualize, slice and dice the data, and then use it for future plans. Tracking these and other metrics also helps manufacturers justify whether a specific solution has helped them improve (or not).

Put these Must-Haves on Your Shopping List

If your company is grappling with any or all of these shortcomings in a sales and operations execution (S&OE) solution, it’s time to explore scheduling applications built by companies like Arkieva. Look for software that includes built-in algorithms and templated options that will help you minimize changeovers and maximize overall efficiency on the manufacturing floor. The base system should include all of the fundamental scheduling capabilities you’d expect from an advanced solution, but it should also be intuitive and malleable enough to be easily fine-tuned for your own operation, without the need to write code or make major adjustments to the application’s output.

The Arkieva Finite Scheduler is designed from the ground up to support the needs of the modern supply chain and its many different links. With Arkieva, manufacturers get incredible power, ease of use, and the flexibility to tackle the unique problems their businesses face. Like the rest of the Arkieva suite, the scheduling application is designed for discrete batch or continuous manufacturing operations, making it an effective solution for a wide range of manufacturers.

Continue your journey with Arkieva with the How to Build the ROI Case for Planning and Scheduling on-demand webinar.