I recently read a report from McKinsey & Company titled “To improve your supply chain, modernize your supply-chain IT” that has some interesting points. I wanted to share this space to amplify a few observations.

It seems that we are always reinventing ourselves to meet the latest challenges. Be it staffing, ports, legacy software or just an ever-expanding mix of products and customer expectations, there is always something. Often the solution to this “something” comes down to managing the big 3: people, process, and technology.

In terms of technology, the writers of the article rightly call out that “supply-chain leaders haven’t done themselves any favors by clinging to manual systems and antiquated software, including one widely used application that’s so old the provider will soon stop supporting it”. Hint: they are talking about SAP APO. APO was launched in 1998 and has been sunsetting for about the last 8 years – and it now seems 2027 will be the end for APO. So, this should come as no surprise to anyone. Yet SAP is the 800-pound gorilla in the ERP space and is deeply entrenched in many organizations.

As we all know, upgrading and/or replacing supply chain software is a time and revenue consuming activity. The McKinsey report shares information we have all had personal experience with: Companies average 2.8 years from vendor selection to complete rollout. Industries with highly complex supply chains, such as pharmaceuticals, typically spend four to six years and $62.5 million to $125 million to fully implement a new supply-chain-planning system. Industries with less-complex supply chains, such as consumer-packaged goods, can spend two to three years and about $17.5 million on a new system. With so much time and risk involved, pushing forward with even incremental changes can be quite disruptive.

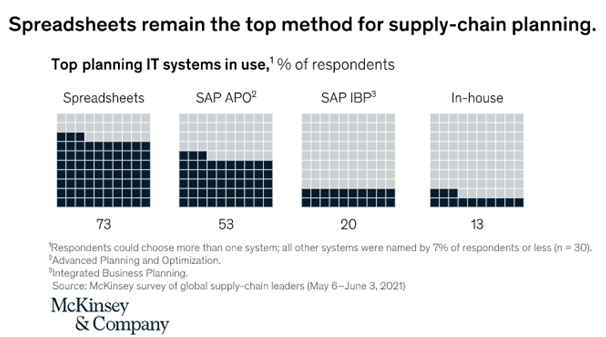

But even with the right technology, people still overly rely on spreadsheets. The idea of automating as much as you can and retiring your “Masters in Macros” has been drummed into our collective consciousness for about the last 10 years . As the chart shows, most have not acted on this. This is especially true for those planners who have SAP or other large ERPs in place – or are only using spreadsheets – which is still a thing, I guess.

Why? I think it comes down to letting go. From my personal experience (as a marketer), I am always exporting data to Excel and manipulating it to get the information just the way I want it. I know that if I rely on data that is fed out of one of the many marketing optimization systems I use, there will be some gaps. So, my natural inclination is to spend hours finessing data to get the 5% of information that is missing. Guess what? The decisions I make with or without this “extra” data are very similar. Only when I rely on the automated data, I get to do more – and have dinner on time. This is absolutely the same for planning inventory or sensing demand. We must begin to “Trust the Force” and use the power of the tools we have. Even if there is parity or a small lift from the technology, the benefit to the “people” part of the process will result in higher employee retention and a more efficient team.

Another challenge that is not addressed sufficiently is adoption. Be it new features or a new platform, unless the end users actually use the product, the investment will be invalidated. Way too many times senior management delivers new technology, and the team views it as getting socks for Christmas when they wanted an X-Box. The McKinsey report calls out the fact that 45 percent of executives in a poll said the biggest barrier to launching an IT project was a lack of consensus on a new system’s technical and process requirements. Another 35 percent said the impact of a new planning system did not meet expectations, and 28 percent said they struggled to create a compelling business case to justify switching to a new system. I would argue that making the business case to the end users is one of the most important barriers to adoption AND providing a path from the conceptual (look what all this cool tech can do) to the actual (look what I did), is probably the hardest to accomplish.

Change is hard. Change is risky. Change is necessary. In this competitive space, staying the same is the same as moving backwards. As difficult as it may be today, you still have a chance to get a competitive advantage by acting now. If you get the right team together and understand the needs across the enterprise and start selling the benefits of the end state early, you will have success. What obstacles have you faced with moving away from Excel and/or adoption of new technology? Share your stories here.

[cta id=’5182′]