A guide on how to improve material planning using a more detailed volume allocation of customer orders.

It is a common business practice to write up yearly contracts for the volume. Very often, this is done to extend volume discounts to the customer. That is obviously a benefit to the customer. The supplier benefits by knowing how much to budget for in terms of production through the year. They can also count on the revenue coming in.

As the customers become aware of their immediate needs, they will place orders against this contract volume. The supplier will schedule production and delivery based on these orders.

However, in between the year contract volume, and the immediate open orders, there is a lot of detail that is missing. As the year goes by, Supply Chain teams need to know how much to produce, how much raw material to order and when. As such, they need to understand a month by month or week by week breakdown of the yearly volume.

Read More: How to Measure Inventory Effectiveness

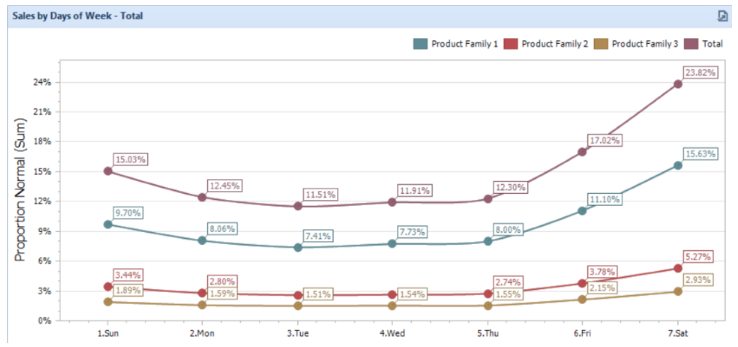

In any case, where an aggregate number needs to be broken down from a large time period to a smaller time period, it is helpful to understand the underlying data. For example, a weekly data set might need to be divided across days:

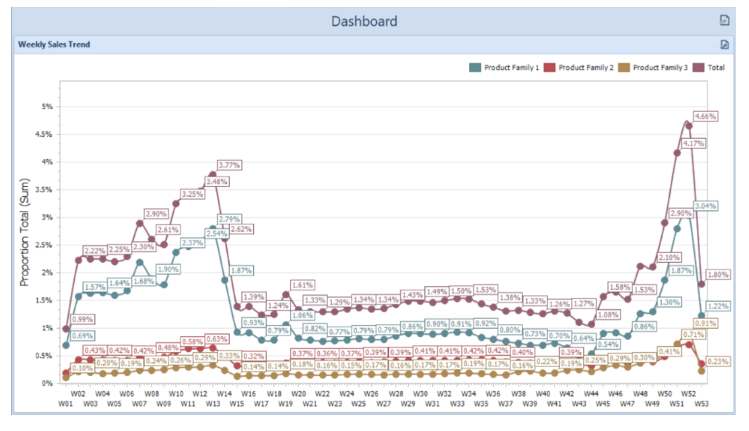

Or a yearly data might need to be divided across weeks:

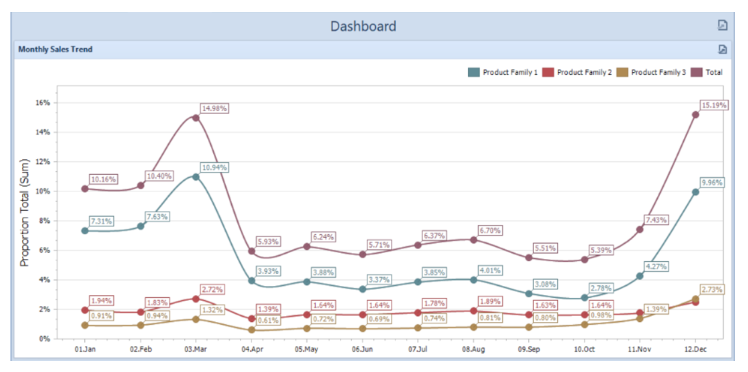

Or a yearly subtotal across months:

These ratios can be established at any level that the data supports: Product family, Product, or customer product. The only thing to keep in mind is that the level should have enough data such that any statistical conclusions are meaningful and significant.

Read More: ABC Segmentation for Inventory Management

Once these monthly or weekly ratios have been established, the yearly contract can easily be distributed using those ratios.

As the year progresses, and actual orders and shipments come in, only the remaining amount should be distributed across the remaining months.

Below are some examples of how to monitor your inventory rates and create inventory allocation policies for yearly contracts. Using inventory planning tools can help streamline this process.

Examples of How to Allocate Customer Order Volumes

As an example, if one finds that out of the annual contract of 12K, 5,000 units have been shipped by end of March, then, the remaining 7K should be distributed across the remaining months based on the available ratios in those months.

Sometimes, these ratio calculations can be rendered useless if the customer orders against the yearly contract at a much faster or slower rate. In such cases, you should deploy certain alerts and take remedial action.

Example #1: High Ordering Rate

For the yearly contract of 12K units, if by the end of March the customer has already ordered and received 10K units. And let’s say that the ratio we calculated suggested that at max, we should have seen demand worth 4K units by the end of March. The much higher demand rate suggests that this should be conveyed to the customer and possibly increase the contract amount.

Read More: Here’s a Simple Way to Create an Effective Inventory Management Process

Example #2 Slow Ordering Rate

In another example if by the end of October, the customer has only ordered 1K, and the ratio we calculated suggested that the demand by the end of October we should have been at a minimum of 7K. This clearly shows a much slower rate of ordering by the customer. If one does not change the overall contract amount, then one would see the classic hockey stick effect, wherein it appears that all the demand will show up in the remaining few months, thereby creating a sharp uptick in the demand rate. This being the case, it makes sense to raise and alert with the customer and ask if they have intentions to fulfill the contract.

This is how I have solved this inventory allocation problem. Have you done it differently? Let me know.

Enjoyed this post? Subscribe or follow Arkieva on Linkedin, Twitter, and Facebook for blog updates