Summary

In supply chain management (SCM) there is an ongoing flow of elixirs (magic potion) from ‘false prophets’ claiming that they are an easy path to improved performance. A recent elixir is IBP followed by “doing central planning at the family level” to neutralize the uncertainty associated with estimating demand at the product level. This blog will illustrate the challenge in this effort since factories produce products, not families. Typically planning at the family level moves the uncertainty from the demand statement to parameter estimation. It will also make clear the danger from an elixir failing to grasp the key to success is ongoing work in the trenches. There are no free rides.

Introduction

One group inhabiting supply chain management (SCM) are “false prophets” peddling the latest elixir (magic potion). Often well-meaning, but nevertheless wrong, ignoring the need for experience and expertise in the trenches in pursuit of the ongoing challenge. A recent elixir is integrated business planning (IBP). The core of the IBP Elixir is sales and operations planning (S&OP) focus is only mid-level decisions and simple balancing of demand and supply. It fails to “optimize” the entire demand-supply network (DSN), including high-level management, and support each decision tier. S&OP is the path to failure, but the new elixir, IBP, is the path to salvation. This ignores that best-in-class writings and implementations of S&OP dating back to the 1990s understand the need for an end-to-end view across all levels of management and supporting what-ifs. The limitation is not in S&OP but works in the trenches. Even at Arkieva, ignoring your own past can be convenient when the new prophet speaks. A Practical Guide for Improving Sales and Operations Planning, by CEO Dr. Harpal Singh, covers all of the key items in the “new” and better IBP. Dr. Singh often was an invited speaker on the theme “optimization should not be viewed as the improvement of one decision-making point in SCM.” Additionally, the award-winning work from 1995 to 2004 by Arkieva’s Dr. Alfred Degbotse makes clear the importance of agents of change (p.2) for successful central planning.

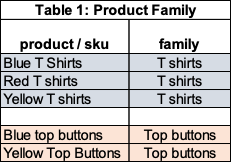

What about CPE Planning Level? In CPE, central planning engine, often the term supply planning is used. It is a model that matches assets with demand (MAD) across the demand-supply network (DSN) to coordinate activities across the DSN with respect to the best interest of the firms. The planning level is best explained with the example in Table 1. Our firm makes 5 unique shirts where each belongs to one of two families. The question is whether to build and run the CPE at the product level or family level.

The remainder of this blog addresses this question.

What level is best for planning?

The current “elixir” is planning best done at the family or more generally an aggregate level and not the product or SKU level. The reasoning is:

- The forecast error is higher at the product level (perhaps 70%) than at the family level (perhaps 30%). Therefore, executing the CPE at the product level has no value since the input (demand) information is wrong.

- The firm is crunching extra numbers because it is now possible, but the detail has no value.

- A CPE at the family level will solve is 5 minutes compared to 60 minutes at the product level. IF the CPE is run 5 times a week, the planners lose about 4.5 hours a week waiting for the model to solve what has the wrong results.

Having been part of a team of best-in-class agents of change who explored the advantages and disadvantages of planning at the family level compared to the product level 25 years ago where the executive sponsors determined it was better to aggregate across time than families, I jotted down some of the team’s reasoning in story form.

The Story

As anyone trained in statistics knows, forecast error is not a measure of error, but of uncertainty, where we attempt to place the structure on uncertainty with probability. Once the product is eliminated from the CPE, then it is eliminated from what-if analysis whether you are doing S&OP, central planning, or IBP.

Besides demand information, the CPE requires quality information on how to make the exit and intermediate entities (product or family) (see what is a DSN?). Since the manufacturing folks do not produce families, but products, the source information at this level is readily available. Table 2 has the information on what subset is needed to produce each shirt.

Each shirt uses the resource color tank (column 2) for a certain amount of time (column 3) and consumes the appropriate dye (columns 4 and 5). The different dye colors (blue, red, and yellow) belong to the dye product family. Additionally, Red T-shirts use the resource “set color”. The manufacturing puts red shirts through a special process to keep the dye from bleeding. OAK stands for “one of a kind tool” – meaning there are just one of these tools in manufacturing and the business monitors this closely to determine if it needs to purchase an additional tool.

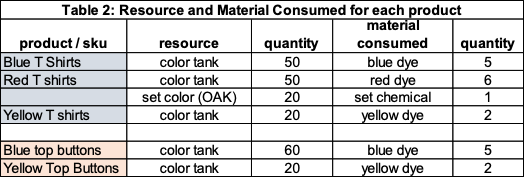

The SCM demand planners and their manager, having recently attended a webinar about the latest elixir from the prophet, inform the SCM supply planners that resources and material consumed at the family level are now required. They send Table 3 to the supply chain supply planners and tell them to fill in the question marks (?). Notice the family “dye” is used for material consumed.

Since the supply planners are not the source of the build information, this request is sent to the factory planner. The factory planners then huddle at lunch with the tool planners, who immediately point out (with passion), we do not produce and consume families, but products (parts). The senior factory planner informs them we must send something back to the SCM folks. What to do?

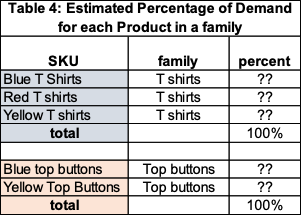

At this point, they ask the old guy with an office near the manufacturing director who has no obvious work but has been around for a while and seems to be called upon for special missions. He looks at the request and creates Table 4. He instructs the factory folks to tell the SCM folks that once they have this table filled out, the factory can send them the family information needed.

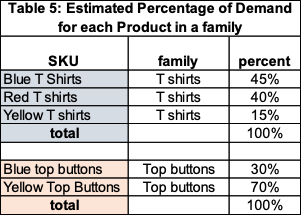

The demand planners have this information from the product level demand estimate that is still done but no longer used. Since they have committed to implementing family planning in two weeks, they immediately use these numbers to fill in the “??” (table 5) and send it back to the factory.

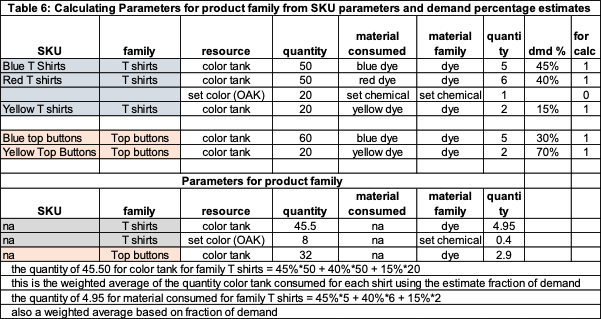

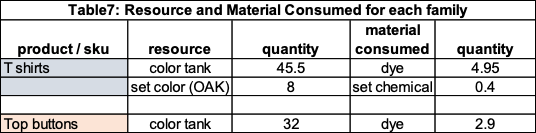

The factory planners immediately take this information to the old guy, who puts the values into an excel based model (Table 6) to calculate the information needed by the supply chain. He provides them Table 7 to send to SCM.

It is important to note the value of 45.5 for the quantity of the color tank consumed per unit of production of the family T-shirts is the weighted average of the consumption quantity for each actual T-shirt in the family (blue, red, and yellow). The weight is based on the estimated fraction or percentage of the estimated demand for the family T-shirt. Yes, the same unreliable values are now in the model, simply at a different entrance point. This same process is used to estimate than other production parameters at the family level.

The SCM folks, especially the manager of demand planning, are thrilled. In four weeks she has been able to have a CPE executing at the family level and eliminated all of the uncertainty associated with product-level demand estimates.

One minor disappointment was the reduction of the solve time when transitioning to family. The family model only ran 10% faster than the product level model. The IT folks suggested running 5 different models overnight, the results were ready for the planner in the morning. Therefore, the time to finish the question was never pursued.

The question about analyzing the probable workloads on the OAK tool remained critical. This directly depended on having a range of estimated sales of Red T-shirts and later the new product Red top buttons – probabilistic forecasting.

Since SCM was now operating at the family level, they said they were not able to directly address this question. However, the improved accuracy of the central plan (since it was not operating at the family level) offset this need. However, the VP of manufacturing technology and the director of manufacturing knew it was a critical question that needed to be addressed. They assigned it to the old guy who it turns out started at the firm with the VP of manufacturing technology. He had an old friend in demand management, and they created a series of demand estimates at the product level to help address this question. An example of community intelligence.

As a result of the success of moving from product to family in SCM the manager of demand planning was promoted to SCM director, and the elimination of uncertainty was heralded wide and far.

Conclusion

Of course, if you have been paying attention, the use of uncertain product-level demand estimates simply moved from the demand statement to a back level communication in an Excel file from SCM to the factory planner to the old guy. The old guy had automated and extended the logic to estimate family level parameters which read in the Excel and posted family level production specifications to the official table that personalized the CPE.

The failure to see a substantial improvement in the performance of the solve time of the CPE was never determined. However, the addition of lot sizing and binaries (to insure for any given time bucket only T-shirts or button-ups were made, but not both) dramatically increased solve time.

Of course, after a reasonable period of time elapsed, a new Elixir appeared (perhaps demand priorities or too much variation in the build process between products in a family) that required planning at the product level.

The old guy simply kept notes for his memoirs and went golfing until the next Elixir appeared.

Enjoyed this post? Subscribe or follow Arkieva on Linkedin, Twitter, and Facebook for blog updates.