Supply chain planning improvement involves a series of projects separated by periods of institutionalization. Unfortunately during these periods there are many opportunities to regress to the “old ways of doing things”.

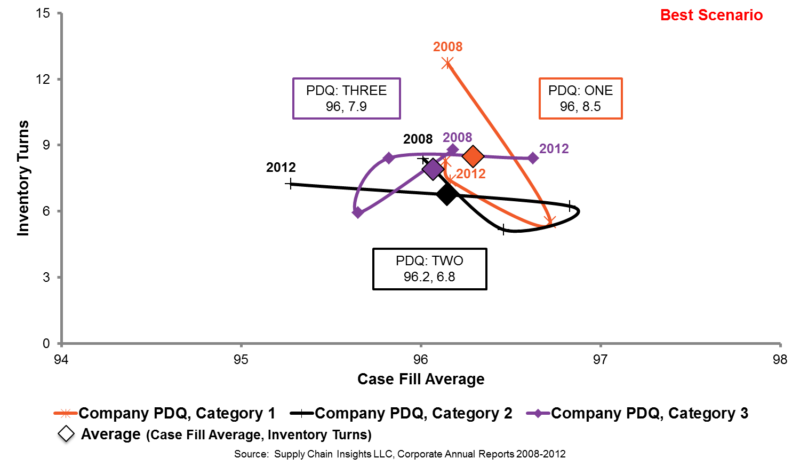

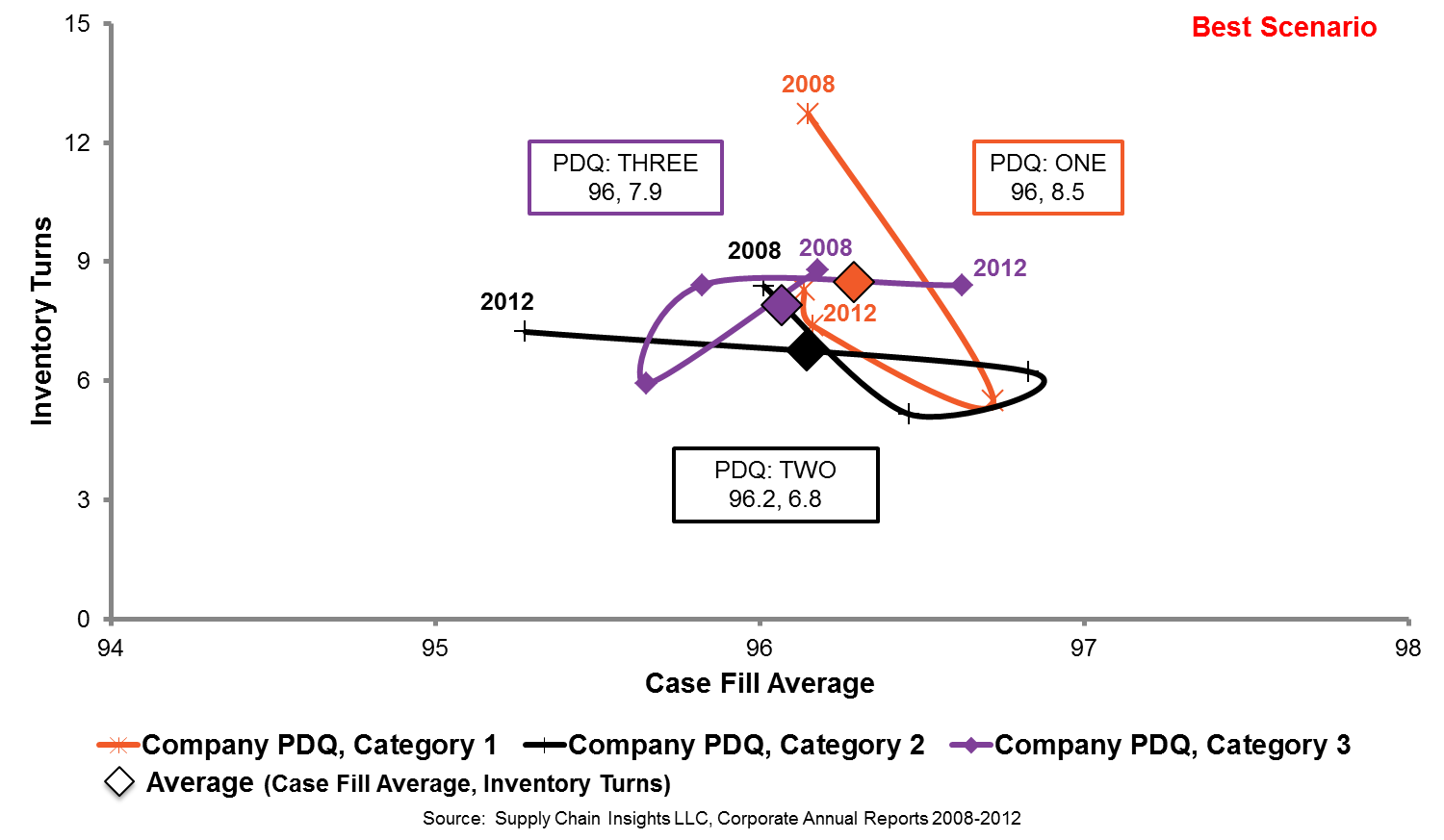

Industry thought leader Lora Cecere mentions and depicts this phenomenon in her research through the use of orbit charts (see chart below). Over the years companies improve techniques whether managing inventory turns as pictured below or forecasting, etc., but then continually regress and then improve and then regress and then so on and so forth.

In Arkieva’s experience, a successful project is necessary but not sufficient for sustainable supply chain improvement. In this blog post, we’ll discuss 3 reasons why improvement projects backslide and 3 ways to combat them.

Problem #1: The planning software chosen doesn’t do what I need it to do

A modern supply chain software is flexible, it can be configured to do practically anything. But even though the initial implementation addresses a company’s needs, over time business conditions change. If the software does not adapt to the changes, it becomes too cumbersome and people invent alternatives. In today’s environment, creating these alternatives is relatively easy with desktop tools like Excel and Access. Although these homegrown systems may appear to help at first, they often end up as isolated applications that need a lot of care and feeding. As a result, data becomes decentralized, and the old inefficiencies creep back in.

Solution #1: Search for improved software

Many companies try to use software to enforce compliance to the processes embedded in the software system. Our experience is that this is not successful because planners tend to gravitate to spreadsheets and other aids as mentioned above. The net result is that a number of parallel processes are developed and the software system becomes increasingly irrelevant. The more successful companies understand that software tools and systems must elicit the commitment of the users. They need to be adapted to changing circumstances so that they can continue to support the S&OP process effectively. It is helpful if the chosen software is configurable and adaptable past the go-live data so that it can be tweaked to accommodate the business process changes.

Problem #2: The end-users move on

Supply chain planning applications are often developed with heavy involvement from the initial users. While such involvement ensured their success, it also meant that certain ways of doing things – unique to the initial set of users – were introduced as well. In addition, large companies often do a poor job of preparing and training replacements for professional jobs like planning. Frequently the employee new to this job has a limited time to acquire the skills and absorb the intricacies of the tools that need to be managed. The net result is that the application is used less frequently and gradually is replaced by spreadsheets or other applications that may be simpler but less effective.

Solution #2: Provide ongoing training

Provide ongoing education and training to those functions that can impact the supply chain by their decisions. This includes process as well as software specific training. Companies typically allow training but do not require it. Be sure that your supply chain professionals whether new or old upgrade and improve their skills. It is helpful in this regard to remember that schedulers and planners do not complete clerical activities. They frequently make decisions that alter working capital by millions of dollars. Decisions of this magnitude that affect other assets in a company usually require an extensive training and review process.

Problem #3: The planning is too successful

Supply chain improvements usually occur in response to specific business needs and are articulated in terms of a business crisis like too much inventory, missed shipments, etc. Since many of these issues are mitigated with proper supply chain planning, it is difficult to quantify the benefit of something that eliminates problems before they occur. Over time, planning is perceived as no longer an issue and the business process is streamlined to eliminate much of the planning function.

Solution #3: Consider supply chain planning and execution to be a key competency

Once improvements have been made it is important to recognize that ongoing efforts must be made to maintain an advantage in supply chain operations. Often companies have a distinct supply chain organization with the same clout as the manufacturing, logistics and sales organizations. Some actions to maintain this advantage include developing a structure and a budget that allows the supply chain to rapidly respond to business crises and making sure that the supply chain decisions are transparent. Transparency is the first step to fostering internal collaboration.

Like this blog? Follow us on LinkedIn or Twitter and we will send you notifications on all future blogs.