The current “focus” on tariffs and how organizations can intelligently respond to an abrupt change in the playing field is a reminder of the critical importance of building and maintaining quality central planning models for its economic well-being, if not survival. Quality is defined as (1) capturing the complexity of the demand supply network and (2) including robustness and responsiveness in addition to profit in your evaluation criteria. This reminder occurs with increasing regularity: COVID, hurricanes (impacting hospitals), tsunamis, port strikes, infant formula shortage, etc.

The twin pillars of the central planning process (CPP) are: (a) demand estimation and (b) matching assets (production capability, inventory, purchases, etc.) with demand to synchronize the “creation process” to identify what demands will be met when and what additional assets may be needed.

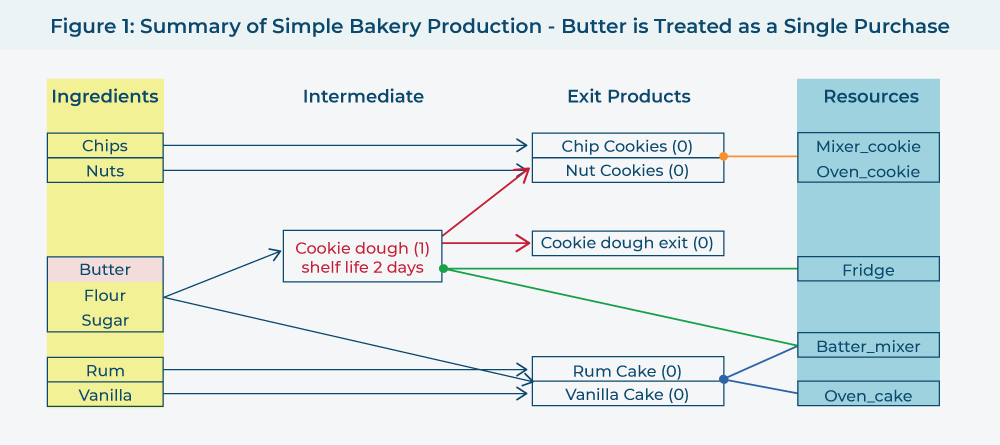

Although every firm does CPP, there is a vast difference in the capabilities of the models to support this decision making. Some firms rely on simple models (even if they are using linear programming). Simple being defined as the level of complexity of the demand supply network captured in the model and the ease of analyzing alternatives. Figure 1 has a simple bakery model where butter is treated as a simple purchase. A more complex model is captured in

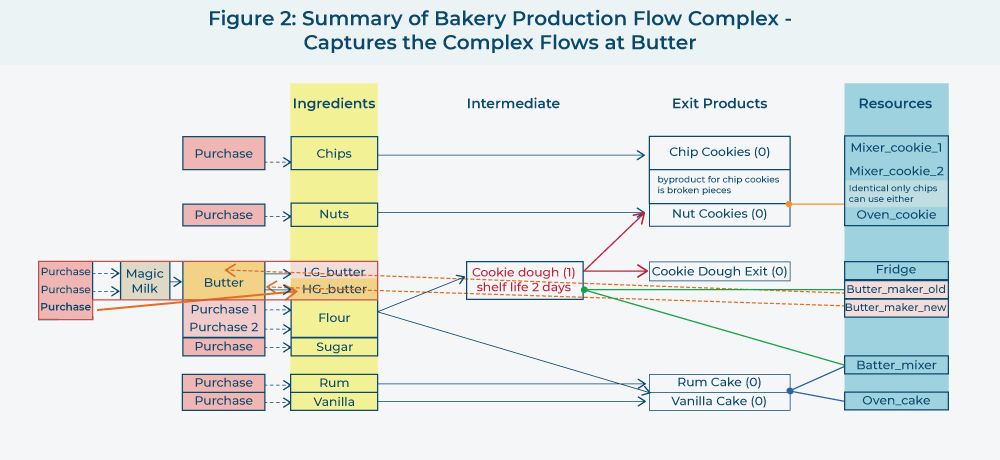

Figure 2 where the butter “section” captures additional details such as two types of butter (low grade (LG) and high grade (HG)) and two alternatives to acquire butter: internal production and purchase. The central planning model based on Figure 1 is simpler to maintain, easier to understand, and works when the business environment isn’t in flux. However, if tariffs increase the cost of purchased butter or a hurricane shuts down the location where butter is produced, this model is of ZERO value to find intelligent alternatives. Second, the simple model with a focus only on reducing cost might source all butter from a single factory, leaving the business no alternative when tariffs “burst on the scene”. Figure 2 inserts a level of complexity that may not be needed on a regular basis. How does an organization get the best of both worlds? It identifies a partner with strong software and “in the trench” skills in addition to modeling skills to develop and implement a solution that can seamlessly support different needs.

Essentially incorporating Kahneman’s well established concept of “fast and slow” thinking into SCM. This is a topic we will return to in our series on artificial intelligence and managing your demand supply network – out of the fog – stay tuned.