Hint: some of these examples will help you finally put your high school algebra to good use.

I work with clients that utilize our supply chain optimization software to maximize their resources. In my upcoming webinar “Should I Optimize My Supply Chain Planning?” I’ll dive deeper into the concepts of supply chain optimization and show examples of when it’s ideal to optimize and when it’s less ideal. Click here to learn more.

In today’s blog post, I’d like to simplify this concept by looking at some basic equations and scenarios to explain how “solvers” or supply chain optimization algorithms work.

Supply Chain Optimization Problem Examples

Now, let’s have some fun with two simultaneous equations.

Two Simultaneous Equations involving ticket sales

The easiest place to start is to go back to algebra and word problems that involve two simultaneous equations.

Example 1: Finding the number of ticket types sold

To solve this problem, all we need to do is follow four simple steps:

- Investigate the problem to understand key decisions and relationships. In this case, this step is handled by the word problem description itself.

- Identify the decision variables – what is the unknown that we want to figure out from our detective work?

- Write a set of equations that describe the relationships between the decision variables.

- Send these equations to a “solver” that does the legwork to find the values of the variables that make each equation “true.”

Simple Algebra Solution:

Part1: Define the Decision Variables or unknowns.

- The number of adult tickets will be x.

- The number of children’s tickets will be y.

Part 2: Write the relationships between these variables, number of tickets sold, and total revenue as two equations. That translates the word description into a math description.

- Equation 1: Handles the total number of ticket relationships (x + y = 1000).

- Equation 2: Handles the total money collected (8.5x + 4.5y = 7300).

Thus, the two equations are:

1.0x + 1.0y = 1000

8.5x + 4.5y = 7300

Now in algebra, you would play with these two equations (called symbolic manipulation) to find the value of x and y that makes both equations true.

We do something like:

(-4.5) {1.0x + 1.0y = 1000} à -4.5x + -4.5y = -4500

Then add the two equations together

{-4.5x + -4.5y = -4500}

+ {8.5x + 4.5y = 7300}

——————————–

4.0x + 0.0y = 2800 à 4x=2800 à x=700

Once we know x, then we can find y, which is 300.

However, doing this kind of symbolic manipulation is fine for a high school and college level student, but in practice, you want to simply send the equations to a solver that has a numerically based algorithm to get you the answers.

Hence we have “solvers” that are numeric algorithms embedded in computer programs that find solutions to problems that can be described in “equations” (actually relationships) without human intervention. An entire body of knowledge and expertise has developed.

[Read More: Can Supply Chain Optimization Lead to a Road Less Traveled?]Using a Supply Chain Optimization Algorithm or “Solver” to solve the equation

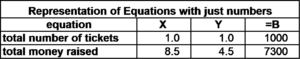

The “SOLVER” doesn’t want the ‘x’ and ‘y,’ it just wants the numeric data, we can represent the equations as follows:

Numeric data (call this MAT) =

![]()

Pass MAT into the solver, and it sends back 700 and 300.

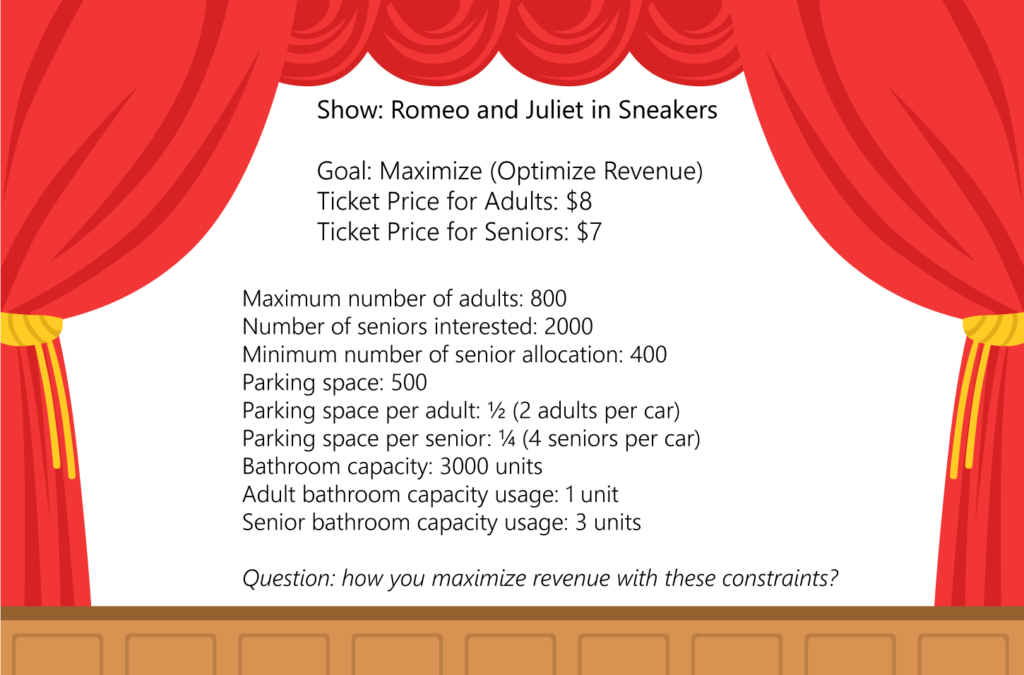

Example 2: Maximizing Revenue for Ticket Sales with Constraints

Let’s alter example 1 to make it a simple “optimization” question.

Our theatre has 1200 seats, and our goal is to maximize (optimize) the revenue we receive for the performance of “Romeo and Juliet in Sneakers” while also meeting some key objectives.

Example 2: Awesome Theatre Location and Ticket Information

The sales price of a ticket is $8 for adults and $7 for seniors. The maximum number of adults who could come to this event is 800. There are at least 2000 seniors who would be interested. To maintain good long-term relationships with the senior community we need to allocate at least 400 tickets to seniors. The two most complicated “restrictions” involve available bathroom capacity and parking capacity.

The theatre only has 500 parking spaces. Historically adults come in pairs (that is two adults per car). This means each adult ticket consumes 1/2 of a parking space. However, seniors come in groups of 4 (4 seniors per car). This means each senior ticket consumes 1/4 of a parking space.

The theatre has limited bathroom capacity – 3000 units. Each adult consumes 1 unit of capacity. Each senior consumes three units of capacity.

What is the decision variable?

- A = number of adult tickets

- S = number of senior tickets

What are the “constraints” that bound the solution?

- available number of seats in the theater – the equation for this is A + S ≤ 1200

- maximum number of adults who will come to the event – the equation is A ≤ 800

- maximum number of seniors who will come to the event – S ≤ 2000

- minimum number of senior tickets we must sell S ≥ 400

- Parking space limitation (1/2) A + (1/4) S ≤ 500

- Bathroom limitation (1)A + (3)S ≤ 3000

What is our objective to optimize revenue?

- Revenue = (8)A + 7(S)

The equations or relationships are:

Maximize Revenue = (8)A + 7(S)

Subject to the following requirements (constraints)

A + S ≤ 1200

A ≤ 800

S ≤ 2000

S ≥ 400

(1/2) A + (1/4) S ≤ 500

(1)A + (3)S ≤ 3000

Now we send the relationships off to the solver and get an answer.

[Read More: How to Determine the Best-Fit Plan with Supply Chain Optimization]

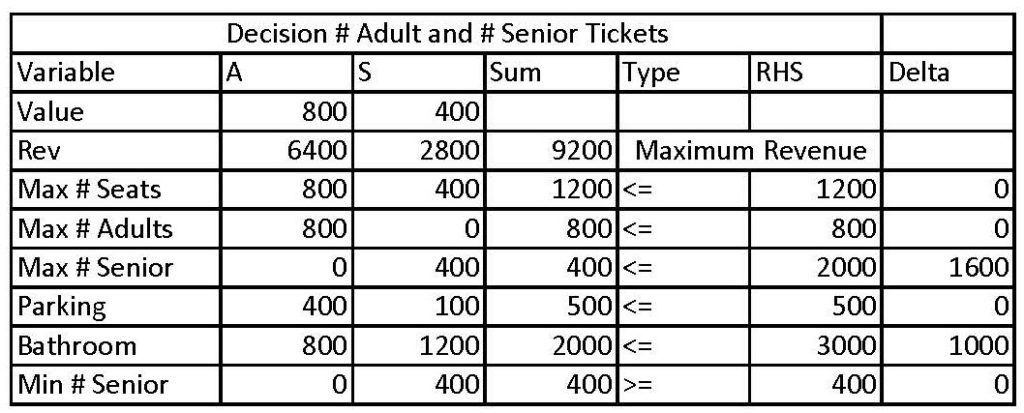

The optimization Algorithm informs us we can maximize profit by selling 400 tickets to seniors and 800 tickets to Adults. It also provides other critical business information.

- The number of seniors is the minimum required and 1600 seniors will not get in.

- If we expand capacity of the theater we will need to add parking.

- Currently we have some spare bathroom capacity.

Again, we have the following core components:

- Investigate the problem to understand key decision and relationships. In this case, this step is handled by the word problem description itself.

- Identify the decision variables – what is the unknown that we want to figure out from our detective work?

- Write a set of equations that describe the relationships between the decision variables.

- Send these equations to a “solver” that does the legwork to find the values of the variables that find the “BEST” solution.

- Create an iterative process to fine-tune the model and use it for insight and exploration.

Certainly, the business scenarios that we handle using supply chain optimization often hold greater complexity, especially when there are larger data sets, multiple constraints, and objectives. I hope this simplified version of how optimization solvers work helped you get a better understanding. If you’d like to see more real-life examples of how businesses apply supply chain optimization to their business, you might enjoy my upcoming webinar.

Enjoyed this post? Subscribe or follow Arkieva on Linkedin, Twitter, and Facebook for blog updates.