Your demand planning process is complete and demand statement is created; excellent, but the sales and operation planning journey is far from complete – the next critical step is matching or balancing assets (capacity, materials, people and projected supply of finished goods) with demand to answer three questions that are part of being a responsive organization:

- How to intelligently meet demand given available assets, the production and distribution network, and business policies?

- What do I need to do to meet unmet demand? Trade-off with demand, improving the asset position, and/or reducing the demand position?

- How to synchronize the activities of the supply chain or demand-supply network?

Answering these questions requires a computational model that captures the relationship between production decisions, consumption of resources, and the creation of exit parts. There are two primary approaches to support management and planners in answering these questions:

- Rough Cut Capacity Planning (RCCP)

- Production Planning or Supply Chain Planning – sometimes referred to as Supply Planning (SP) or Central Planning Engines (CPE)

The methods deployed differ based on the level of granularity, the inherent nature of the industry, organization specific requirements, and the algorithm(s) used to match or balance assets with demand. Often, but far from always, RCCP is a good place to start since it is simpler, inherently more intuitive, and often a path to the more powerful methods in supply planning (aka the “genie” mathematics of optimization)

Typically in Rough Cut Capacity Planning (RCCP) a high-level model that relates demand to the consumption of assets is structured; the planner makes the decision on how to align key assets with the demand; the model is run using the planner decisions as input and calculates the impact of the planner’s decision; a set of output tables is placed into a dynamic planner workbench analytics environment to enable the planner to understand the impact of the decision and support iterations. Typically a detailed projected supply of exit parts is not created. It is critical to note RCCP is a model type, not a specific model. Let’s look at a very simple example.

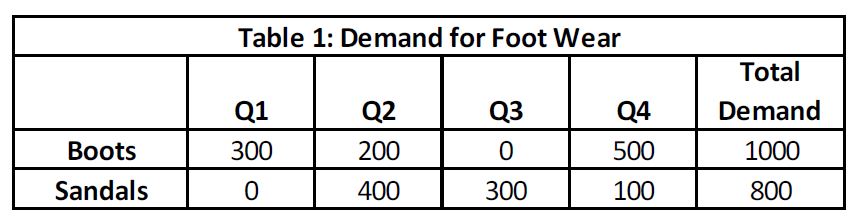

The footwear company produces two products – boots and sandals – and has estimated quarterly demand for each product as follows:

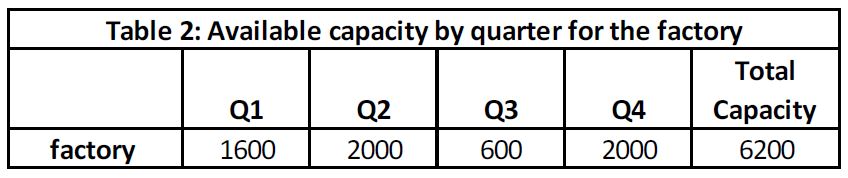

For simplicity we assume there is one manufacturing facility to produce both boots and sandals and we view the factory as a single capacity unit. The available units of capacity for each quarter for the factory are:

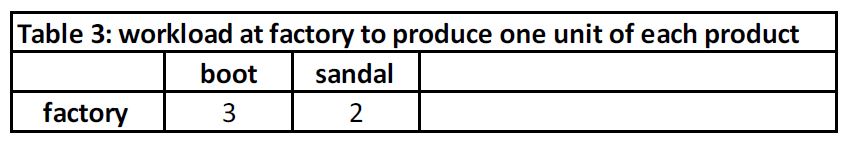

The workload for each boot and sandal three units and two units, respectively:

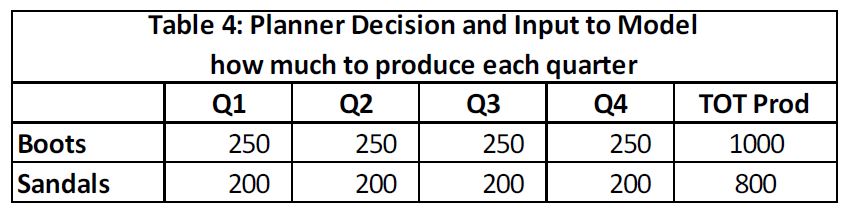

The decision made by the planner that serves as an input to the model is the number of each product to produce each quarter. Table 4 shows this decision, where the initial decision is to divide total demand by four and produce that quantity each quarter.

The role of the RCCP model is to provide the planner information about the impact of this decision on meeting demand, capacity, and inventory.

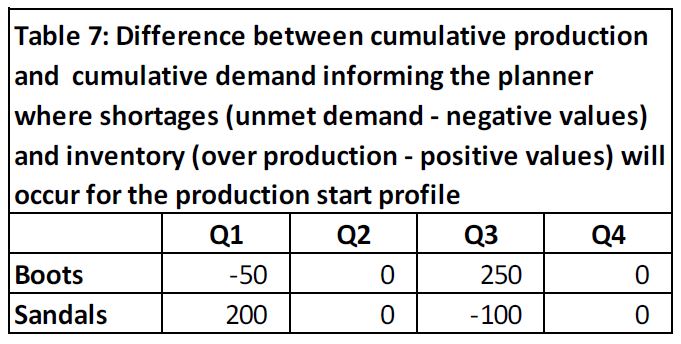

Table 7 (the intermediary calculations in tables 5 and 6 are not shown) informs the planner about the relationship between available supply and demand. A negative value indicates a shortage, which is unmet demand. A positive value indicates inventory is being created.

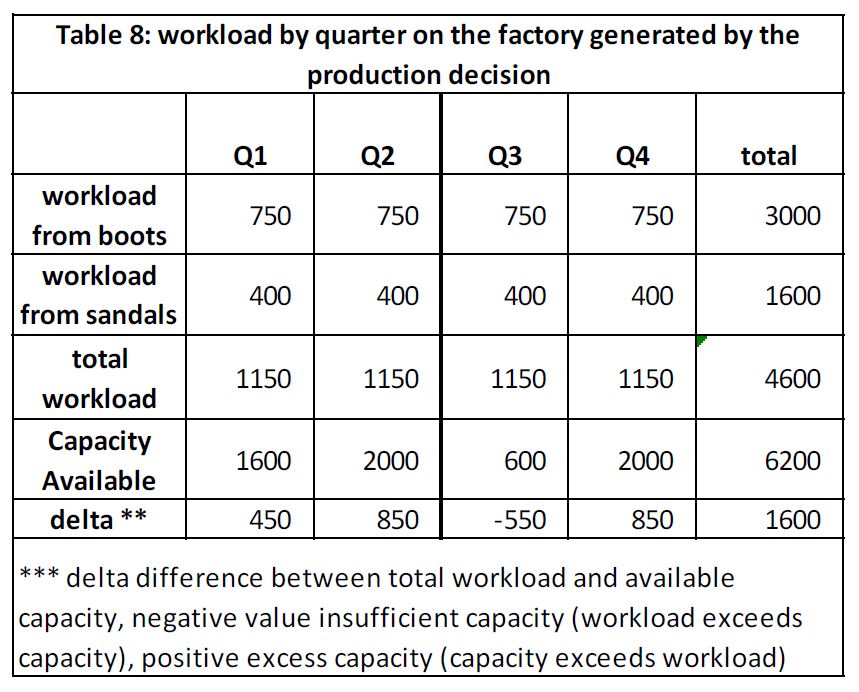

Table 8 informs the planner about the impact of the production decision on the factory. A positive value in the delta row indicates capacity exceeds workload and a negative value indicates an insufficient capacity to meet workload.

RCCP models scale up quickly to capture key aspects of the relationships between production, capacity, and demand in an intuitive and flexible manner. This facilitates planners and managers from different organizations to agree on the nature of key relationships, the sources of data to instantiate the model, and run rapid what-if scenarios – that is better understand their demand-supply network. Often the first RCCP model is making a significant business contribution in a few months.

RCCP models have and continue to be effective models in many situations – for large firms and small firms. We have seen and have firsthand experience the successful use of such models in many industries such as semiconductor, chemicals, pharma, health care, etc. The most recent example seen at Arkieva the work done at McBride.

Additionally, such models often serve as the pathway to the successful development and use of more “sophisticated” Supply Planning (SP) or Central Planning models. Below are two examples from IBM semiconductor manufacturing where the initial work using RCCP later led to the successful use of more sophisticated methods.

In SP, a more detailed model of the demand-supply network is structured that relates consumption of assets with demand, the planner provides guidance (for example demand priority) on how to align assets with demand, the model is run using the planner guidance as input making decisions on how to align assets with demand and calculates the impact of the model’s decision. Click here to view a quick comparison between SP and RCCP.

Net is RCCP is often, but not always, an effective method to for the next step: “can” or “how” do I meet this demand. Remember the goal is to optimizing the entire process, not just the model result.