In my experience with several different companies, it is evident that companies make great decisions some of the time. Unfortunately, being successful only some of the time doesn’t cut it. The key to business success is to make good decisions all of the time. Company success is much like investment success. It requires a disciplined process to evaluate ever changing data and make rigorous judgments about the future. Not all the decisions will necessarily work out, but the hope is that the large majority of decisions will have a positive outcome.

In supply chain, the decision making process is no different. Sustainable success is still achieved through consistency and rigorous evaluation of facts. Everything I refer to from here on out can be found in Supply Chain Planning for the Process Industry, written by Dr. Harpal Singh.

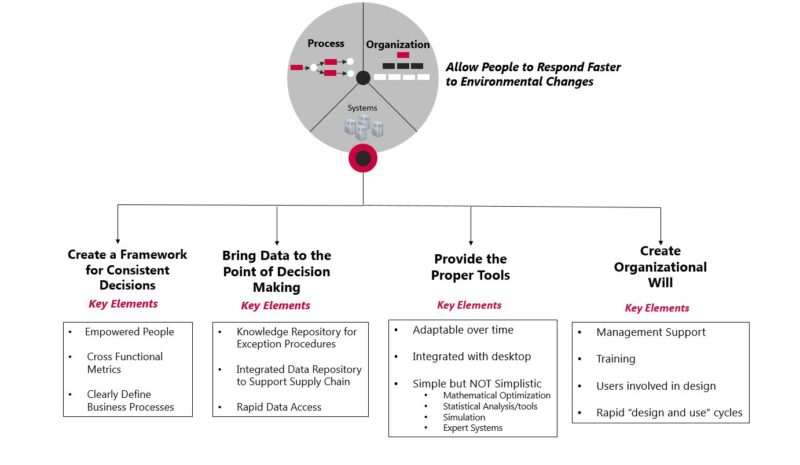

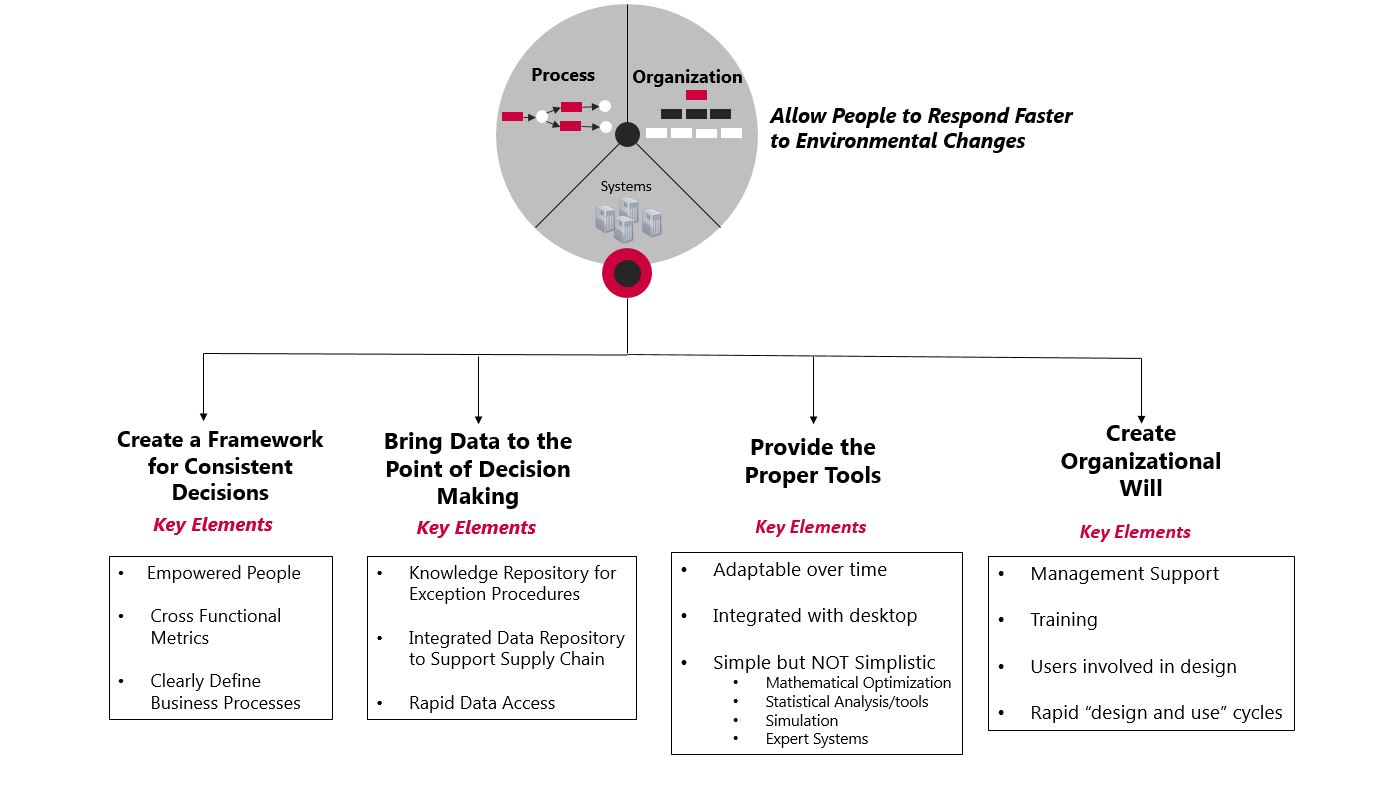

In the chart below, you’ll find the key elements required to move an organization further along and make supply chain planning improvements. The initial key is building a framework for consistent decision making. It’s hard to improve if you are not consistent. Often companies use the sales and operations planning process as the basis for tactical supply chain planning. Having this process in place will empower your people; it defines clear and apparent roles and responsibilities for each individual. At the same time, the metrics need to change as well from those that are directed at individual departments to those that encourage collaborative behavior.

While developing a process is an important prerequisite and a crucial building block, it will not achieve the benefits without delivering the data to the decision makers. There are two major types of data participant’s need, quantitative – demand, inventory, costs and performance – and the rules the organization wants to impose to process the quantitative data. These rules need to be codified so that they reside in a central repository that can be easily accessed.

You’ve made solid progress so far, but, simply defining the rules and delivering that data is still not enough. Each new decision is not exactly the same as the previous one. Participants must be able to employ the necessary tools to manipulate the data. Not all of the tools may be needed all of the time, but they still need to be available when they are required.

Finally, sustainable change requires management participation and support. Without active and constant support, improvements tend to fade away over time.

Of course this is just one opinion. I would love to know what you have to say on this topic. Please leave your comments below.

To request Supply Chain Planning for the Process Industry and learn more, please click here!

Like this blog? Follow us on LinkedIn or Twitter and we will send you notifications on all future blogs.