Last post, I talked about the different mindsets as one goes through the planning, scheduling and execution of a family’s vacation to Florida. My attempt was to try and highlight the differences between the three stages. In this post, I will try and pull those concepts into supply chain planning.

In a supply chain related to manufacturers, there are many planning decisions to make. For instance, what should ideally be made where, how much raw materials to buy in advance to take advantage of a price break or when to plan for a maintenance shutdown so that the impact on customer service is minimal? Assuming that a business is somewhat limited by the geography of supply and demand network, the planning process will dabble with these questions. As demand and supply conditions change, the answers will change accordingly.

In modern businesses, this is typically done via a process of sales and operations planning, a process through which a business decides how they want to run their business in the medium term (next 6-18 months).

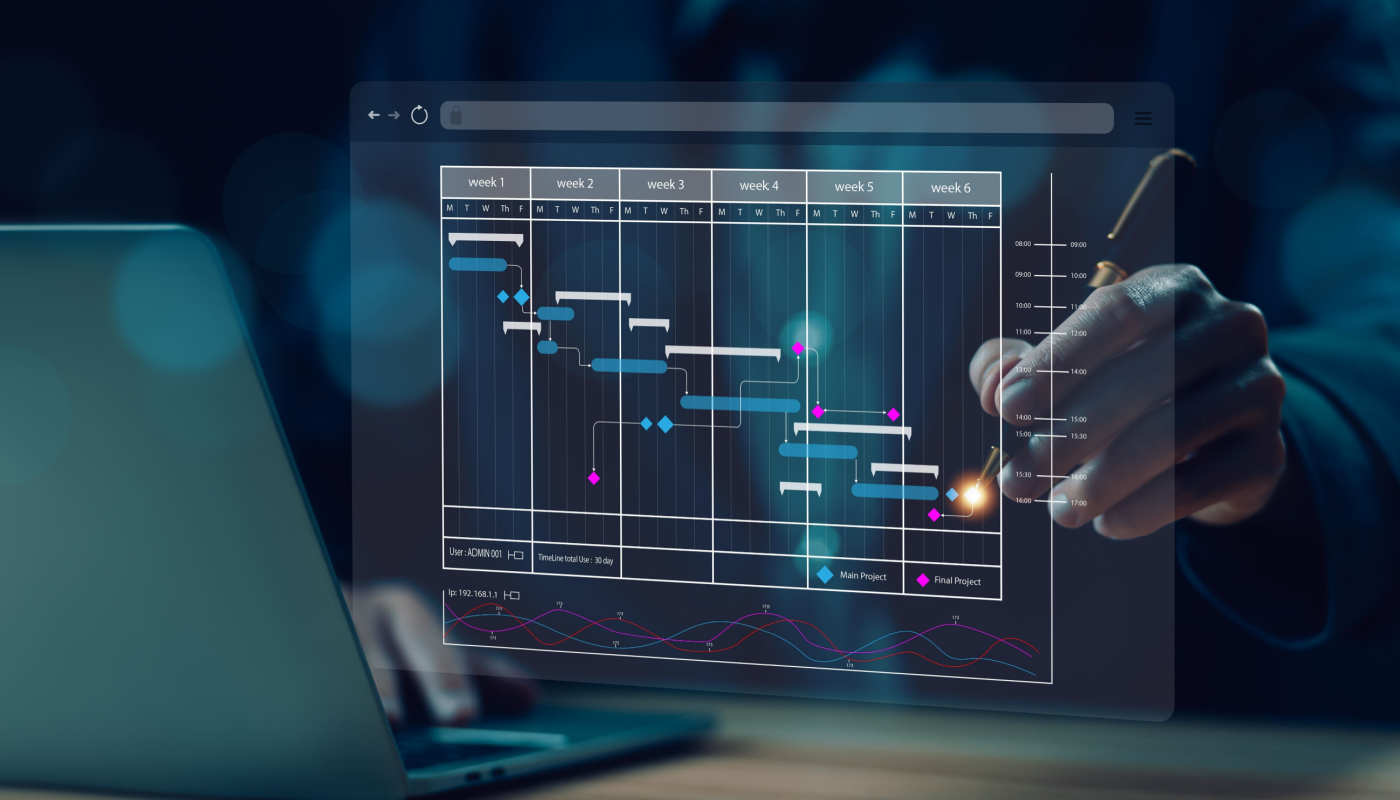

As we get to the short term, businesses still have the plans created above but they are also looking at the latest data conditions as they are changing. They use this data to schedule operations. This could be looking at the relative short term (10-45 days) and is quite flexible. However, while it reacts to the latest conditions, it tries to stay true to the plan. For example, if the plan was to pre-build inventory for future peak demand, the schedule tries to stay close to this plan.

Finally, we get to the very near term and this is where the execution happens. This is the time frame where a business is concerned with shipping out product on time, minimizing disruptions to the production via interjections by management or others in the organization with power to interrupt etc. As one can imagine, at this stage, there is a lot of reacting going on, unless by luck, everything goes as per the schedule, which happens, well, never.

On the one hand, near term is where the customer’s demand is satisfied and money is made and the proverbial rubber meets the road. On the other hand, the near term execution and even scheduling being so reactive, it only allows for firefighting, and small additional gains to the business. Planning is the stage where higher value answers can be found. One of my clients who uses models to do these three stages puts it this way: It is possible in planning to have a multi-million dollar solve; by the time you are in scheduling and execution, you are dealing with very small fractions of that.

Certain industries (food/CPG for example) and businesses of a certain size (< ~ $150M) have a very tough time making the shift from scheduling focused to planning focused. However, history of planning and scheduling suggests that while scheduling is important, planning is where the big value is created. Leaders of small and medium size enterprise should evaluate this for themselves and strive to learn from bigger companies who have already learnt this lesson and have the growth to show for it.

Like this blog? Follow us on LinkedIn or Twitter and we will send you notifications on all future blogs.