Though it sounds like a joke, many executive teams are exactly on this path. In this blog, we’ll define why and how to avoid an infamous future.

Effectiveness equals efficiency. The 1-dimensional view of Supply Chain.

In her book “Supply Chain Metrics that Matter”, Lora elegantly captures that many companies mistake efficiency for effectiveness. To my feeling, it’s much more widespread than we’re willing to admit. Look at your most recent budgeting process. I see many companies define strategies and budgets in an incremental and peanut butter approach like “we’d like you to reduce supply chain costs and inventories with 5% next year”. The 5% reduction stands isolated of any plans on the side of sales, product management or R&D. We look at supply chain as a cost. The only way seems down. This budgeting approach signals a lack of a well-defined business strategy, and a lack of alignment between the functional leaders. In this type of companies all executives strive to be world-class in their functional area, and the company may end-up being “world-class at nothing”.

Effectiveness equals efficiency or responsiveness. The 2-dimensional view of Supply Chain.

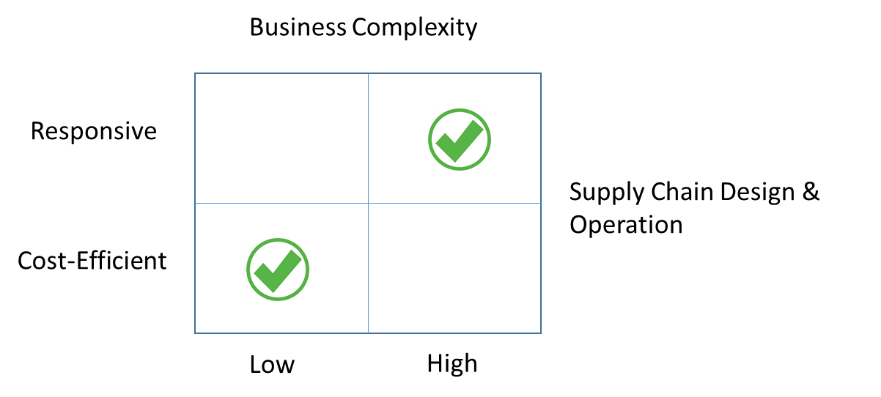

Chopra and Meindl (Chopra, S., Meindl, P., Supply Chain Management, Strategy, Planning and Operation, Fourth Edition, Pearson, 2010) extend the 1-dimensional view of the supply chain into 2 dimensions. They argument that in essence, a supply chain is either cost-efficient or responsive. The type of supply chain you need, depends on the complexity of your business.

I’ve seen multi-nationals comparing the supply chain KPI’s of business units, without accounting for the business complexity. The goal is simple: drive down costs, increase efficiency. The danger is obvious, on the long term a cost focus degrades responsiveness. If your supply chain is out-of-sync with the business complexity, you will be destroying business value faster than you’re creating by the lower cost.

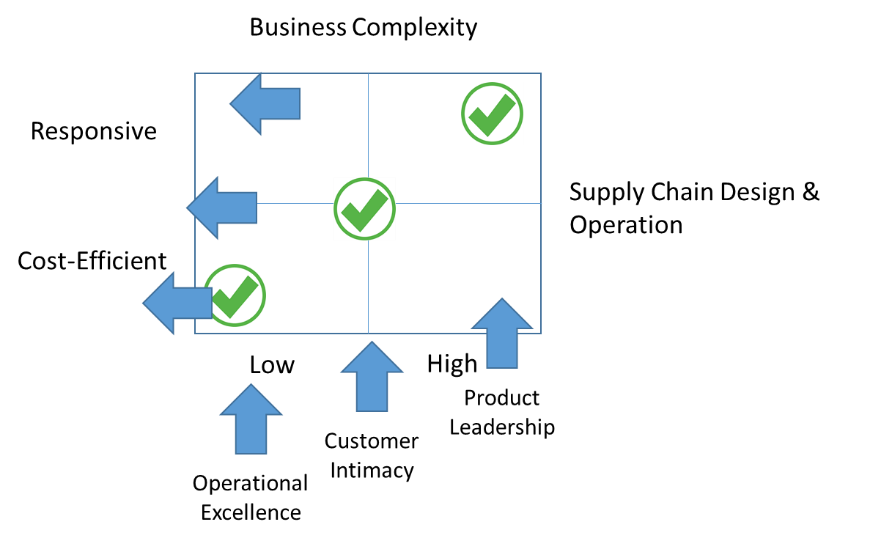

Simple as it is, we believe the basic principle that supply chains are either cost-efficient or responsive, that more responsiveness comes at a higher cost. The downside of the model of Chopra and Meindl is that the characterization of ‘business complexity’ is vague and imprecise. We like the model of Treacy & Wiersema to drive a strategic choice in the level of business complexity which in turn will help defining the level of responsiveness/cost-efficiency of its corresponding supply chain.

Measuring Business Complexity using Treacy & Wiersema

In our blog “Linking the Supply Chain Triangle to Strategy” we have first introduced the strategy model of Treacy & Wiersema (Treacy, M., Wiersema, F., The Discipline of Market Leaders, Basic Books, 1995). They argument that a business can excel in only 1 of 3 chosen strategies.

The product leader prevails by ensuring a continued stream of high performance and highly innovative products. As we have argumented in our blog we believe the supply chain of the product leader to be the most complex. Because the product leader sells his products at a significant premium, the higher supply chain cost is not an issue. It is a requirement to run this type of business.

The operational excellence or opex leader is the cost leader. He excels in the basics and translates simplicity in lowest overall cost which allows the lowest price in the market. In our previous blog we have positioned the opex leader to have the lowest complexity which allows to be run at the lowest cost.

The customer intimacy player will carry extra complexity to nurture the relationship with the customer. That extra complexity drives a premium from the customer but only to a level so that costs and complexity remain below those of the product leader.

When benchmarking supply chain costs, you should always account for the chosen business strategy. We’ve summarized that in Figure 2.

Supply Chain Excellence is effectiveness in supporting the business strategy

In summary, supply chain excellence is effectiveness in supporting the business strategy. If your business strategy is to be a cost leader, than for sure, cost efficiency is effectiveness. If your business strategy is to be a product leader, than excellence in different KPI’s like “New Product Introduction Cycle Time” will be pre-dominant. As mentioned in the introduction, we still see many executive teams caught up in a 1-dimensional view of supply chain which is cost-driven. The lack of an overarching business strategy and the lack of alignment may have these companies end-up as being “world class at nothing”!