When many companies produce products, they also produce by-products. Often, they have no use for these by-products and so they are discarded or sold off as scrap. But companies that embrace sustainability do not accept this fate. Some companies, like Herr’s Snacks, have found a way to turn their waste streams into revenue streams. At Herr’s, wastewater is used for irrigation, sludge for fertilizer, and potato skins for fodder for local farms. Suboptimal quality end products become cattle feed. Wait! There’s more! Steam generated from cooking the potatoes is recovered to heat the buildings. Starch is collected and sold to paper manufacturers. And those corrugated boxes used for shipping are used over and over and over again. Now that’s a circular supply chain!

Sure, these practices solve many environmental problems while simultaneously improving the bottom line, but they can also wreak havoc on manufacturing and production planning processes. Because of this, it is critical to integrate sustainability and circularity in your supply chain planning, indeed into your entire integrated business planning (IBP). We talked a few weeks ago about how some Arkieva clients are doing this with energy management. This week, we’ll see how to adjust your supply chain planning system when you re-route your waste.

One of Arkieva’s clients, whose mission is firmly planted in sustainability, found a way to take their by-products and turn them into sellable products. But converting the by-product into a finished product required some additional processing. The good news is that they already had the equipment they needed. The bad news is that they were using this equipment for their existing products. Suddenly, parts of the manufacturing process flow went from linear to circular because the by-products need to go back to an upstream process for further refinement. Production planning and scheduling just got a lot more complicated.

Trying to fit these jobs in after the primary products are scheduled is guaranteed to be inefficient and sub-optimal. Using an integrated supply chain management optimization tool, like Arkieva, clients can seamlessly balance the feeds, the needs, and any other constraints to provide an overall best-balanced plan. Arkieva’s optimization tools will look at the demand for all products and evaluate the routings and production requirements for the original products as well as the repurposed ones. The end result is a plan that is guaranteed to be the least cost (or highest profit if revenues are provided) solution that satisfies all prescribed business rules and priorities.

Sustainable practices can be adopted in all corners of a manufacturing operation, including ethical selection and sourcing of raw materials, energy-efficient buildings, and taking into account externalities through Triple Bottom Line accounting. Not all these initiatives have a direct impact on supply chain management, but when they do, it is important to use a tool that factors in the inherent trade-offs that come with it. By doing so, sustainability and circularity aren’t just “nice” to do; they can improve the bottom line – all three of them, in fact! Arkieva’s most sustainable clients understand that to get the most out of their sustainability efforts, they must manage their supply chain with these new processes integrated into the overall planning system.

If it sounds like these advancements might drive up overall costs and that worries you, then I challenge you to step back and look instead at the bigger picture. Broadening your product offerings also drives up costs (more inventory, more production, more R&D), but you shouldn’t shy away from expansion because it will cost more. The reason is that you get something for that investment – greater value to your customers and better bottom lines. Transitioning to a circular supply chain properly will drive down costs, reduce waste, expand your offerings, and improve your reputation, all without kicking the can of externalities down the road for someone else to address.

To truly succeed, supply chain management cannot be an afterthought to your overall Integrated Business Planning (IBP). Every decision (finance, sales & marketing, production, logistics, AND supply chain) affects the others. The interplay is demonstrated by Bram Desmet’s Supply Chain Triangle, where drivers that affect the three corners – cash, service, and cost – come from all functions of an organization. And the only way to truly succeed is to embrace the interplay and work towards a common goal with common performance indicators.

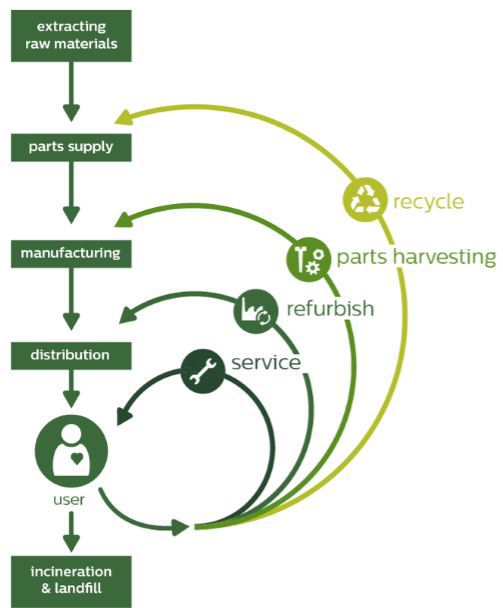

In the same vein, you cannot treat the circular aspect of the supply chain as an afterthought to linear supply chain planning. It needs to be integrated from start (design) to re-start (reuse). Gone is cradle-to-grave thinking; we must enter the age of a cradle-to-cradle mindset.

Enjoyed this post? Subscribe or follow Arkieva on Linkedin, Twitter, and Facebook for blog updates.