What-if scenario planning is an excellent technique that allows a planner to ask questions on the future. Given a working model that represents a business, a planner can quickly ask the questions that represent the range of possibilities in the foreseeable future which can render the current plan obsolete.

NOTE: For a detailed read on how to do what-if scenario planning, you can watch a series of videos on what-if planning. Also read our series on Sales and Operations Planning.

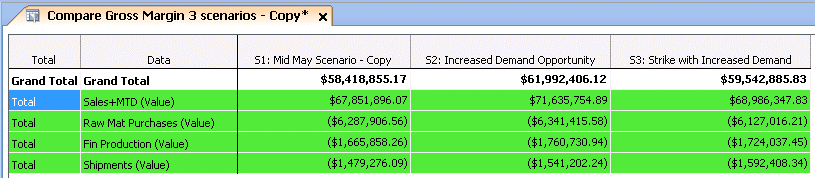

See below for an example of what a report comparing the margin impact of three different what-if scenarios might look like.

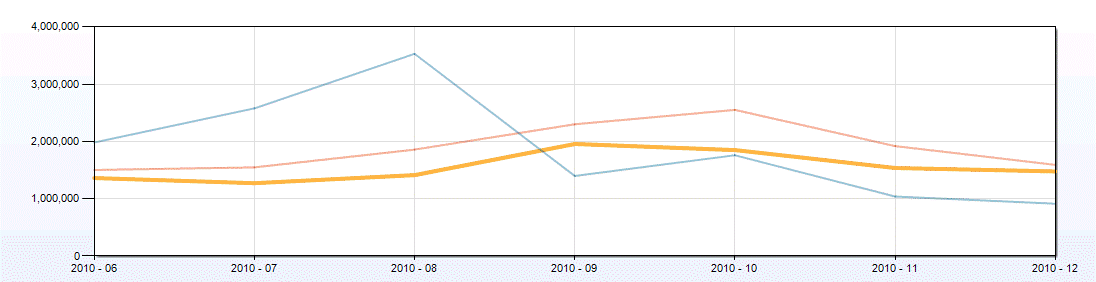

And below is another report comparing the impact of ending inventory based on these scenarios. Notice the spike in inventory in one scenario as compared to relatively flat inventory profiles in the other two scenarios.

To understand this better, let us look at an example. Say, a supply plan was created based on a forecast. However, a forecast is almost always wrong. So, a planner might want to do a what-if scenario that dealt with the question of the demand being too high or too low. In the case of demand being too high, a supply planning model that represents the business can be used to recommend which demand to meet and which to not meet (assuming the capacity is fully utilized). In the case of low demand, the same model might recommend which lines to shut down and when.

Similar examples can happen on the supply side. For example, a key question could be when to take a shutdown on a line. It might be possible to take it next month or the month after next. Again, a representative supply planning model will advise when the better time to take this shutdown is and what the impact might be in terms of missed demand or inventory build ups.

The what-if could be about an extra shift, rising raw material prices, a possibility of a shutdown of a particular shipping lane or a particular supplier going out of business. The list of things that could happen next month is potentially endless (although not all might have the same probability of happening).

Any S&OP process relies on the planner to run the what-if scenarios with the highest probability and bring the results to the S&OP meeting for discussion with the executives. A key question then is: What is a minimum number of scenarios that should be run every month? And what if any of those scenarios will actually happen.

Best practice shows that about 3 to 5 scenarios in each S&OP cycle are ideal. Any more and you risk spending too much time on them. Any less and you have not done due diligence. We are talking about what-if scenarios that deal with the variations in the steady state of the business. High/low demand or capacity, raw material price increase etc. are all examples of that.

Strategic or long term what-if scenarios are best handled through a different process which could be an opportunity to try out many of these scenarios. This is the process where you evaluate what-ifs around geo-political changes, major natural events etc. Bringing these types of scenarios into the S&OP process could be counter-productive because the users could feel they are irrelevant.

And what about the question whether a what-if scenario plan is of any use if that particular what-if scenario does not come to pass. There are two ways to answer this. First, while it might not happen this month, it could happen a couple of months down the road. Second, and possibly more important, the very experience of thinking through a what-if scenario can prepare one to think differently. It also allows a planner to exercise the what-if muscle so they can quickly evaluate a what-if situation when the real need arises.

Of course, you might totally disagree with my suggestions, in which case I am interested in hearing from you. Please provide your thoughts via comments section.

Like this blog? Follow us on LinkedIn or Twitter and we will send you notifications on all future blogs.