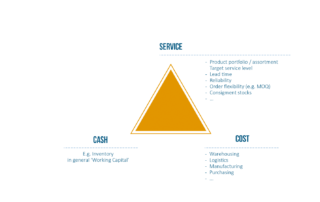

Balancing Cash, Cost and Service: The Supply Chain Triangle

When launching an inventory reduction program, success is contingent on keeping the Supply Chain Triangle in balance. However, keeping Cash, Cost and Service in balance may prove difficult for a traditional supply chain organization whether the business is a success or if it is struggling. Please read more to learn how to deal with pressure within the Supply Chain Triangle.