“Given the choice between changing one’s mind and proving there is no need to do so, almost everyone gets busy on the proof.” ~ John Kenneth Galbraith, Economist

Last week, I traveled to Phoenix, Arizona with the Arkieva team to attend the Gartner Executive Supply Chain Conference. This year’s conference theme was ACT: Aspire, Challenge, and Transform in a Disruptive World. During the flight, I sat next to a business executive for a large chemical company. And as with most flights that are Wi-Fi enabled, most passengers were busy working on laptops and tablets, lost in our worlds; typing, responding to emails and acting as though our lives would change if we disconnected for a few hours.

When the flight attendants came around with refreshments and glanced over, I noticed the business executive was working on a spreadsheet. Much to my dismay, he pulled out his phone calculator and made a few calculations on his phone and entered the values on his spreadsheet.

I’ll be the first to admit that I shouldn’t have pried, but I was so dazzled by the fact that highly critical company financial calculations were being made using a phone calculator. Let’s forget about using a fancy software solution, what happened to using Excel formulas?

Are You Ready for a Disruptive Supply Chain?

While discussions on disruptive supply chains center on innovative technology solutions such as IoT-enabled devices, 3D printing, self-driving cars, and the like, it’s evident that there is another type of disruption that’s needed in today’s business that is more focused on organizational change. Businesses that get too comfortable and think along the lines of the infamous saying; “if it ain’t broke, don’t fix it,” often miss the chance to revolutionize the way their business operates as technology changes. The missing piece however in some cases is not the inability to plan, or even lack of access to funds for research and development. Sometimes, it’s just mere organizational culture changes that are needed. If a business doesn’t operate with an inherent organizational structure that has embedded curiosity for continuous improvement; you may leave ‘good as good as good enough.’ Or as described in our blog on the cost of doing nothing, you don’t do anything because change is too cumbersome, painful – and simply disruptive.

Going back to the example of using a calculator vs. an Excel spreadsheet, there is technically nothing wrong with making calculations with a calculator. Most Excel formulas, on the other hand, allow for better tracking, give you errors when formulas are not formatted properly, and generally are much better suited for performing complex calculations. While this is true, using an Excel spreadsheet or a more advanced supply chain solution would involve some amount of change and a possible learning curve. And to reiterate the point made by Economist John Kenneth, we prefer to find the proof on why we don’t need to change rather than making steps to change.

[ 5 Spooky Excel Error Tales That Could Become Your Nightmare ]How Do You Manage Disruptive Change?

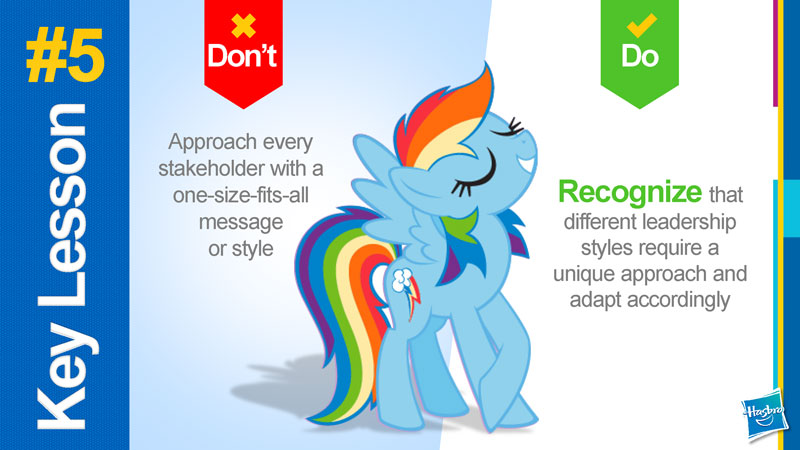

The disruptive technology centered discussions at the Gartner Supply Chain Executive Conference featured a session presented by Ken Chadwick Research VP at Gartner and Kathryn Hanford, Vice President, Business Process Management at Hasbro. The session discussed how Hasbro handled change management and resolved possible change conflicts.

Through this process, they identified Seven dos and don’ts for driving leadership alignment:

- Don’t: Start with process pain points or short-term goals

Do: Focus on the business strategy and benefits – work from the outside in

- Don’t: Assume the program sponsor is the owner or driver

Do: Identify all the key stakeholders and their role in the program

- Don’t: Assume stakeholders understand the program

Do: Reinforce and reiterate program objectives and milestones

- Don’t: Assume ownership equals accountability

Do: Create mechanisms for accountability and ways for stakeholders to shine through measurement

- Don’t: Approach every stakeholder with a one-size-fits-all message or style

Do: Recognize that different leadership styles require a unique approach and adapt accordingly

- Don’t: Assume the job is done

Do: Prepare yourself and your team for a marathon, not a sprint

- Don’t: Rely on one-way communication with stakeholders

Do: Provide opportunities for constructive feedback throughout the process

Finally, it’s easy to get accustomed to what is; get comfortable, ignore the inevitable need for change and stay a mediocre state.

Change is difficult.

When you think about creating a disruptive supply chain think about people, process, then technology. Without the right mindset, an established process, and roadmap to guarantee success, you set up your business for a possible failure when you implement a new technology solution.