Simple Answer: Separating the vital few from the trivial many makes for more productive time to focus on what’s needed for revenue, lower cost to serve, with fewer resources.

The Typical Supply Chain Planner Scenario

As a Planner with over 800 SKUs to manage forecasts, inventory planning, safety stocks and deployment your calendar this week involves:

- Meetings with Sales/Marketing/Manufacturing for the new product launch

- Entering new product data into the product hierarchy and setting parameters

- Creating a forecast for the new product launch along with inventory builds and deployment

- Negotiating with the Master Scheduler to schedule past dues at the weekly scheduling meeting

- Discussing delivery issues with Manufacturing due to quality problems, machine breakdowns, or unexpected yield loss

- Allocating product due to port strikes, warehouse fire, lost shipments at sea, hurricane damage, flooding, railway delays or trucking issues

- Challenging customer orders with Customer Service to protect key customers due to product shortages

- Attending the pre-S&OP Meeting and preparing data for managers

- Participation in training efforts for the new Planner in Korea, China, or somewhere in Europe

- Updating the training manual to document forecasting, inventory planning and deployment procedures

So, with just these ten sample activities when do you have time to review stock outs, low inventory, high inventory, or review forecasts gone wrong and make the analysis to change parameters in the system?

A dashboard to deliver alerts every day would be helpful so you could focus on those issues critical to key customers, product delivery, and revenue. Of course, you could saunter through 800 forecast screens, and the accompanying inventory plans at each warehouse to see what’s there. In my previous post on “How to Track Your Inventory Stock Out Alerts” I went into detail on how to create different severity codes and alerts for managing inventory levels.

Back to our main question, how do you create a dashboard that has the critical information that you need?

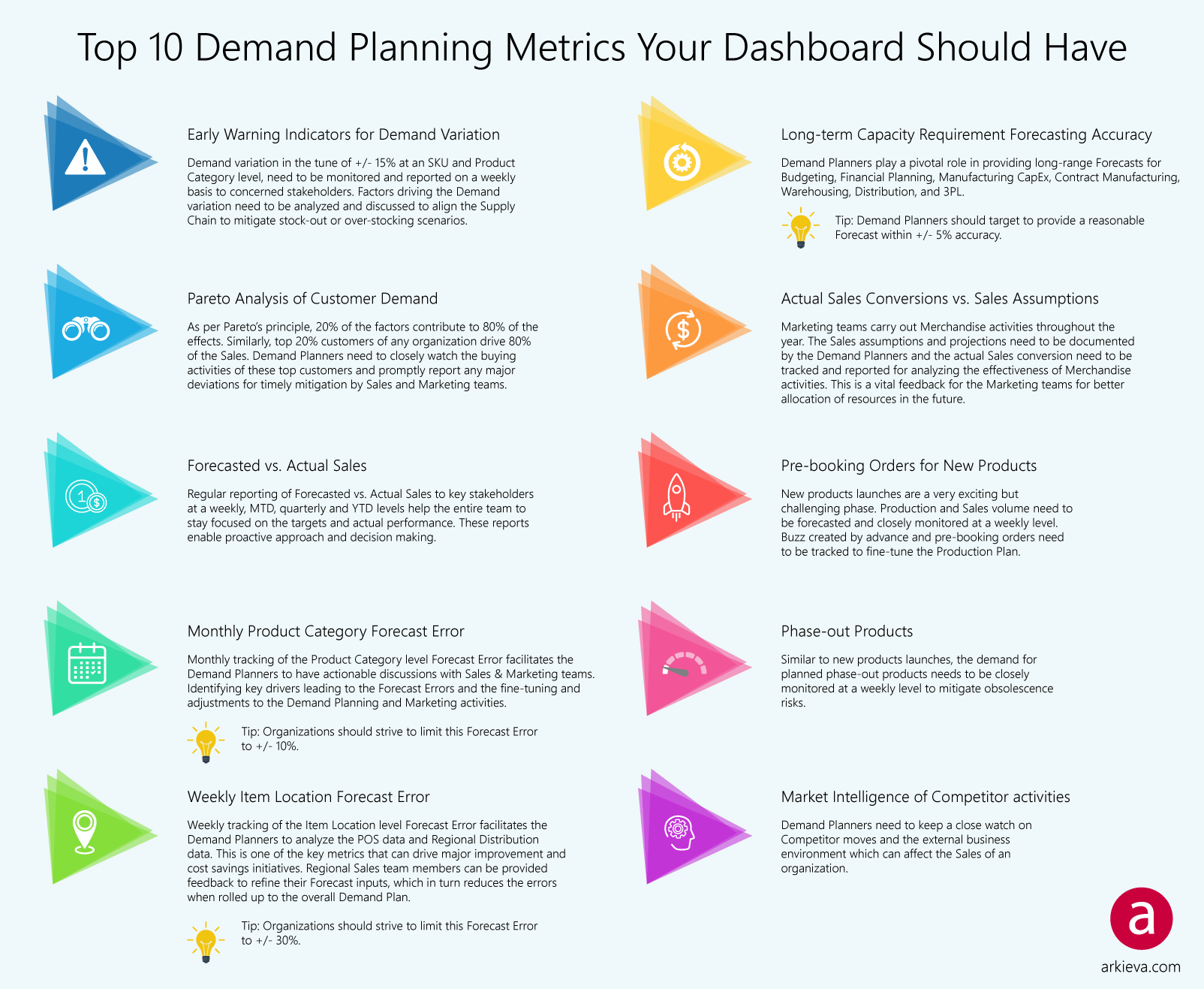

It’s easy to focus on the bells and whistles when it comes to creating an effective dashboarding process. In fact, you could end up with a dashboard that has so much information that you are unable to focus on the important tasks. For instance, the Arkieva “Top Demand Planning Metrics” blog post mentions some of the key demand planning dashboard metrics to track. You may however find that you only need a few critical elements on your dashboard.

In order to create a dash-boarding process that allows for quick analysis of critical information, your planning system needs to be setup to have the following features:

Planning System Dashboard Productivity Tips

- Variation Visibility: your planning system should make variation easily visible. Set up a customer/product segmentation screen that makes it easy to target key customers or new products (phase-in) or focus on old products likely to become obsolete or a costly write off. An ABC analysis of your products and customers can help with this process.

- Automatic Updates: Your dashboard should have the capability to be refreshed as needed without the need for IT intervention.

- Data Validation & Integration: Does the data in the system reflect changes made to transportation lanes, lead times, warehouses, and safety stocks for new and existing products? The easiest way to ensure a more accurate data process is to have your supply chain planning system integrated with your existing operational systems. This includes your transactional ERP systems or warehouse management systems.

- Ability to Quickly Analyze Information: Does the system list key customer-product combinations? Stock outs of these combinations? Severity of the stock out (customer orders with no product in-transit)? Stock out analysis of High Volume-Low Variability? Low Volume-High Variability? Your planning system should be setup to make it easy to quickly retrieve information.

Bottom line

Planning Dashboards that focus on critical issues not only saves precious time and money also means the ‘common’ Planner can do uncommon things. They spend less time fire-fighting and more time on prevention. Additionally, there will be more time to give quality attention to the ten sample tasks listed at the beginning. Well thought out alerts in the dashboard offering pre-planned analysis allows you to do more with less. And with automation, these get delivered every day.

Enjoyed this post? Subscribe or follow Arkieva on Linkedin, Twitter, and Facebook for blog updates.